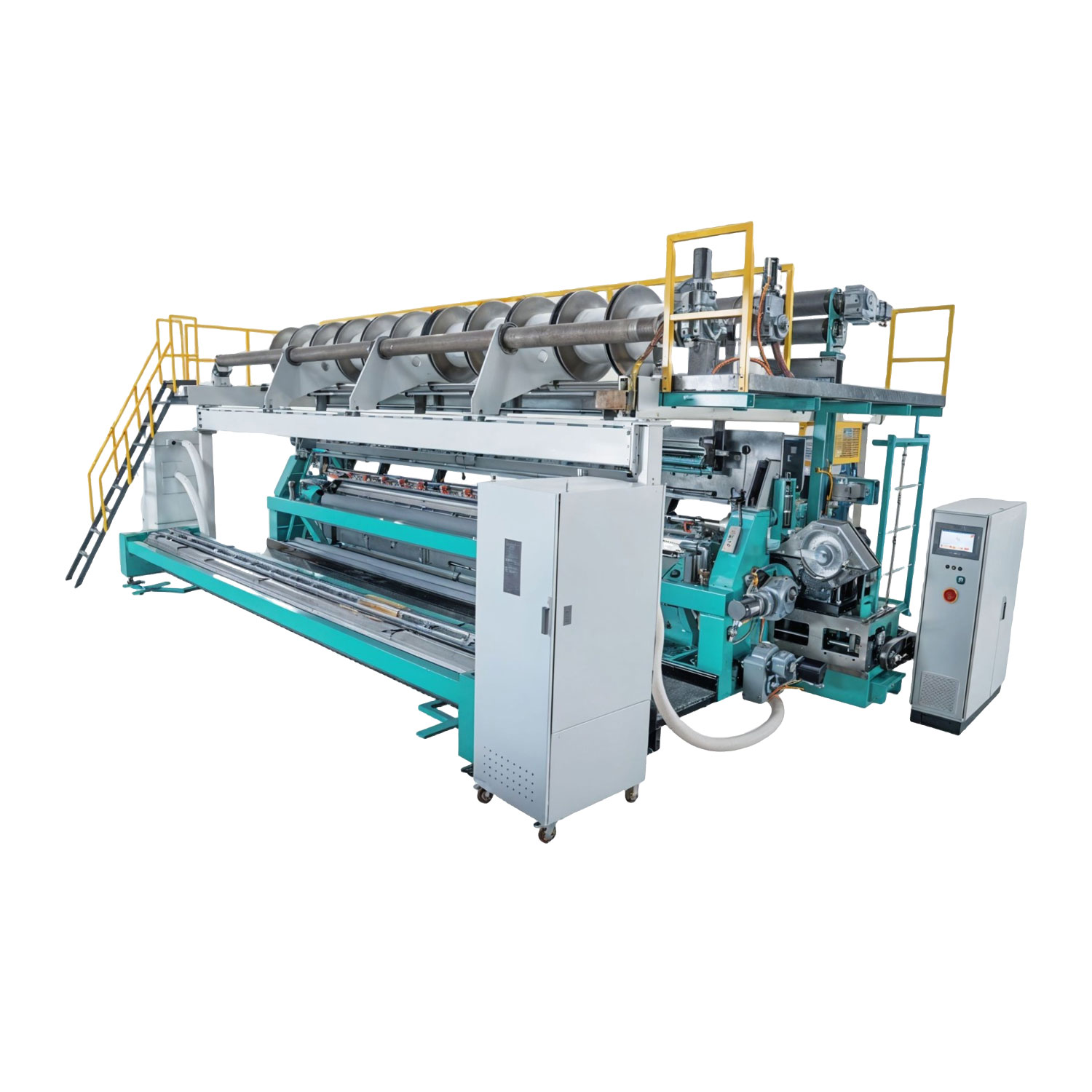

Tricot Warp Knitting Machine with 2 bars

| Tricot Machine with 2 guide bars HKS2 – Warp Knitting Machine | |

| Model No. | GS-HKS2 |

| Ground Bars | 2 Bars |

| Pattern Drive | Pattern Disc / EL Drives |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

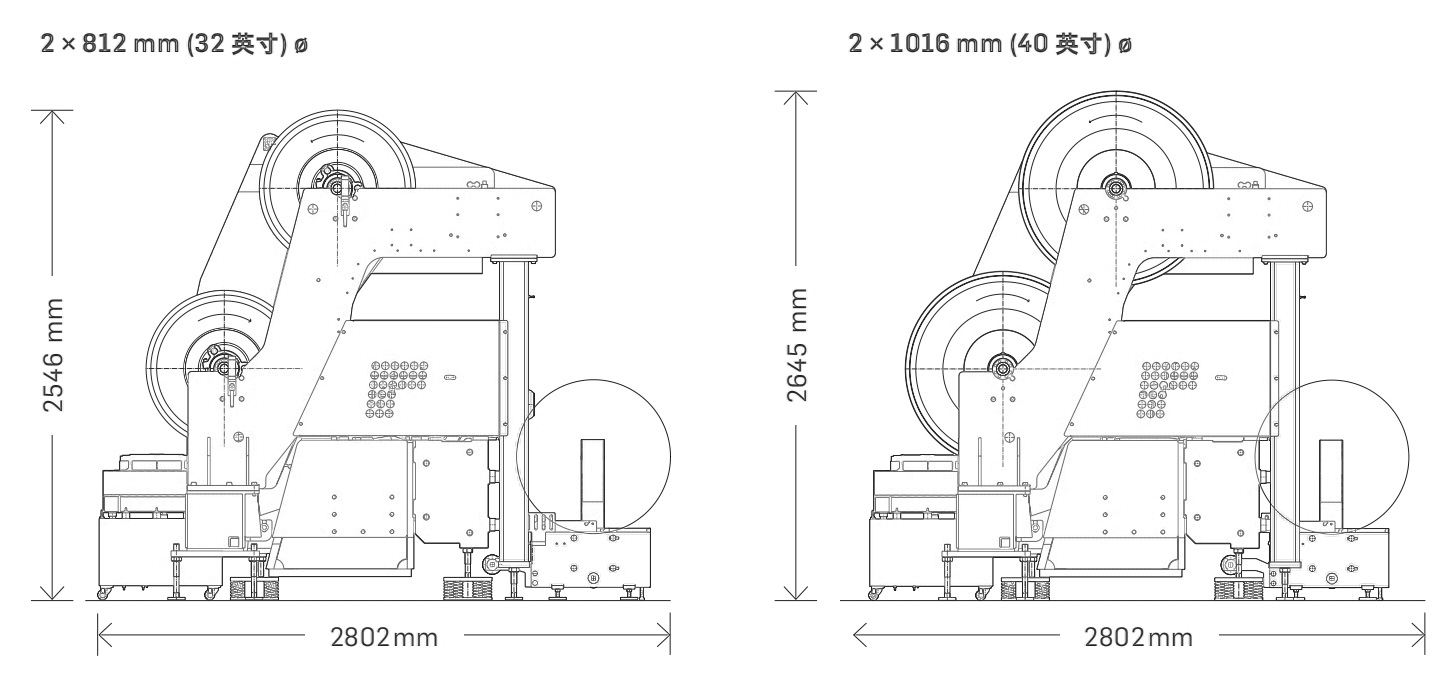

- TECHNICAL DRAWINGS

Working Width and Gauge:

- Working Widths:

- 7417 mm (292″)

- 8128 mm (320″)

- 8636 mm (340″)

- Gauges: E28 and E32, offering versatility for diverse textile requirements.

Bars / Knitting Elements:

- Individual Needle Bar: Equipped with compound needles for precision knitting.

- Slider Bar: Features plate slider units (½”) for stable operation.

- Sinker Bar: Includes compound sinker units to ensure consistent tension and alignment.

- Guide Bars: Two guide bars made of carbon-fiber-reinforced material, ensuring lightweight durability and reduced machine wear.

Warp Beam Support:

- Standard: 2 × 812 mm (32″) (free-standing).

- Options:

- 2 × 1016 mm (40″) (free-standing).

Operator Interface (GrandStar® Command System):

- An intuitive interface allowing operators to configure, control, and monitor machine functionality for seamless operations.

Integrated Monitoring Systems:

- Laserstop: Ensures real-time fault detection and prevents fabric defects.

- Integrated Camera: Enhances monitoring for consistent quality.

Yarn Let-Off Device:

- Each warp beam position includes an electronically controlled yarn let-off drive to maintain uniform tension and thread delivery.

Fabric Take-Up:

- Electronically regulated, with a geared motor and four rollers to ensure smooth and efficient fabric handling.

Batching Device:

- A separate floor-standing cloth rolling device for convenient and organized fabric collection.

Pattern Drive:

- N-Drive: Comes with two pattern discs and an integrated tempi change gear for precision pattern creation.

Electrical Equipment:

- Speed-Regulated Drive: Ensures stable performance during high-speed operations.

- Power Requirements:

- Total connected load: 25 kVA.

- Voltage: 380V ±10% (three-phase power supply).

- Main power cord: Minimum 4 mm².

- Ground wire: Minimum 6 mm².

Oil Supply:

- Oil/water heat exchanger for efficient temperature control and extended machine life.

Equipment Working Conditions:

- Temperature: 25℃ ± 3℃.

- Humidity: 65% ± 10%.

- Floor Pressure: 2000–4000 KG/㎡.

Training & Service

Installation & Training

Localized service teams in Turkey, India, and beyond, along with detailed training formats, reinforce our global technical support leadership.

Local Service

Our after-sales service spans Turkey, India, Vietnam, Indonesia, and the USA, with plans for expansion. In regions without local teams, real-time online support is the first line of assistance, followed by dispatching engineers for hands-on support if necessary.

Application

- Technical Textiles: Creates high-strength fabrics for industrial use, including geotextiles, filtration materials, and protective gear.

- Home Furnishings: Manufactures fabrics for upholstery, curtains, and decorative items with superior quality and durability.

- Lace and Mesh Fabrics: Ideal for creating delicate lace and mesh textiles for fashion, bridal wear, and specialty designs.

- Automotive Textiles: Produces durable and decorative fabrics for car seat covers, headliners, and trim components.

- Medical Textiles: Suitable for creating compression garments, bandages, and other healthcare-related fabrics.

| Working Width | Machine Width |

|---|---|

| 7417mm = 292″ | 9125mm |

| 8128mm = 320″ | 9825mm |

| 8636mm = 340″ | 10301mm |

Explore our world-class warp knitting machines tailored to your needs. Contact us for further details.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |