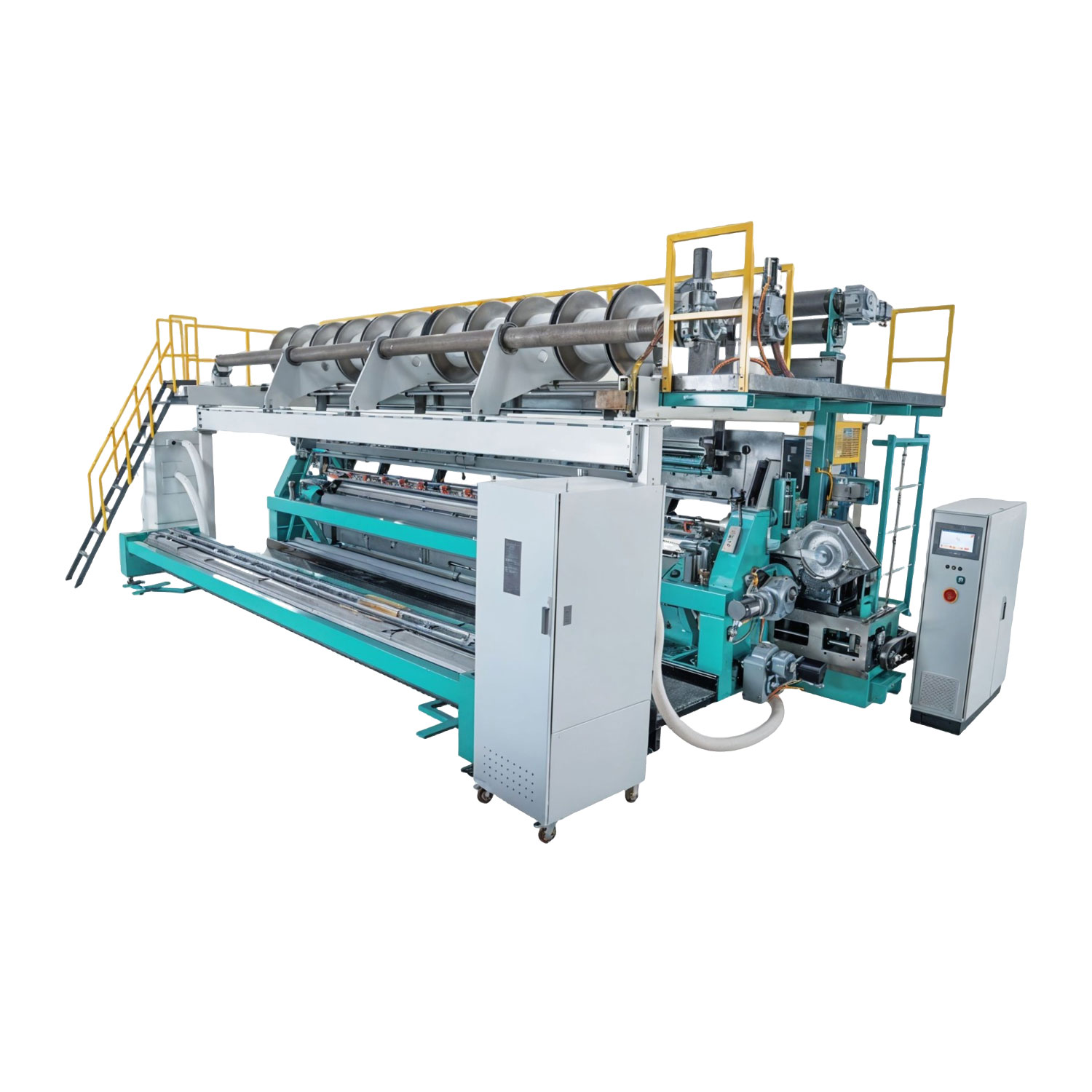

Tricot Knitting Machine with 3 guide bars

| Tricot Machine with 3 guide bars HKS3 – Warp Knitting Machine | |

| Model No. | GS-HKS3 |

| Ground Bars | 3 Bars |

| Pattern Drive | Pattern Disc / EL Drives |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

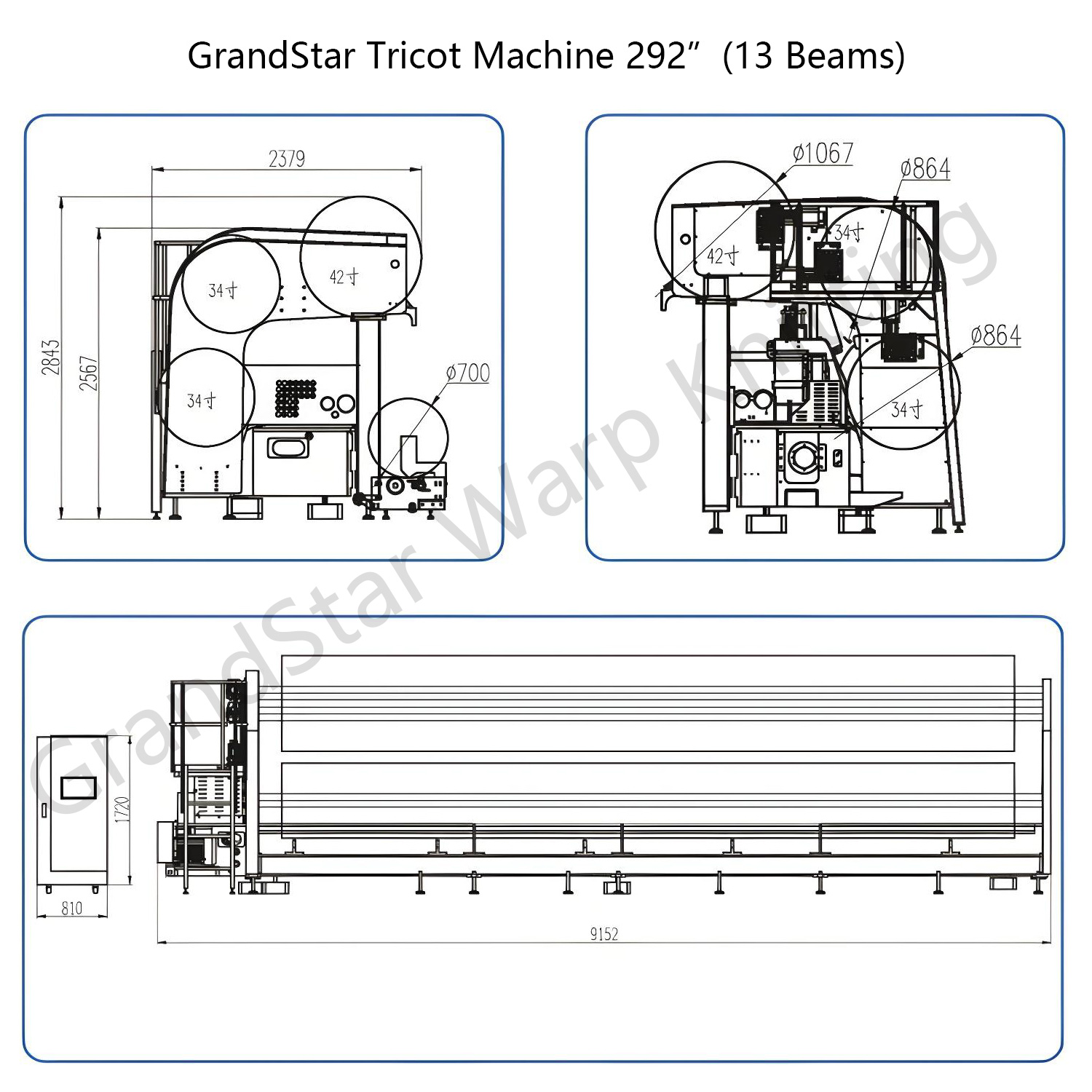

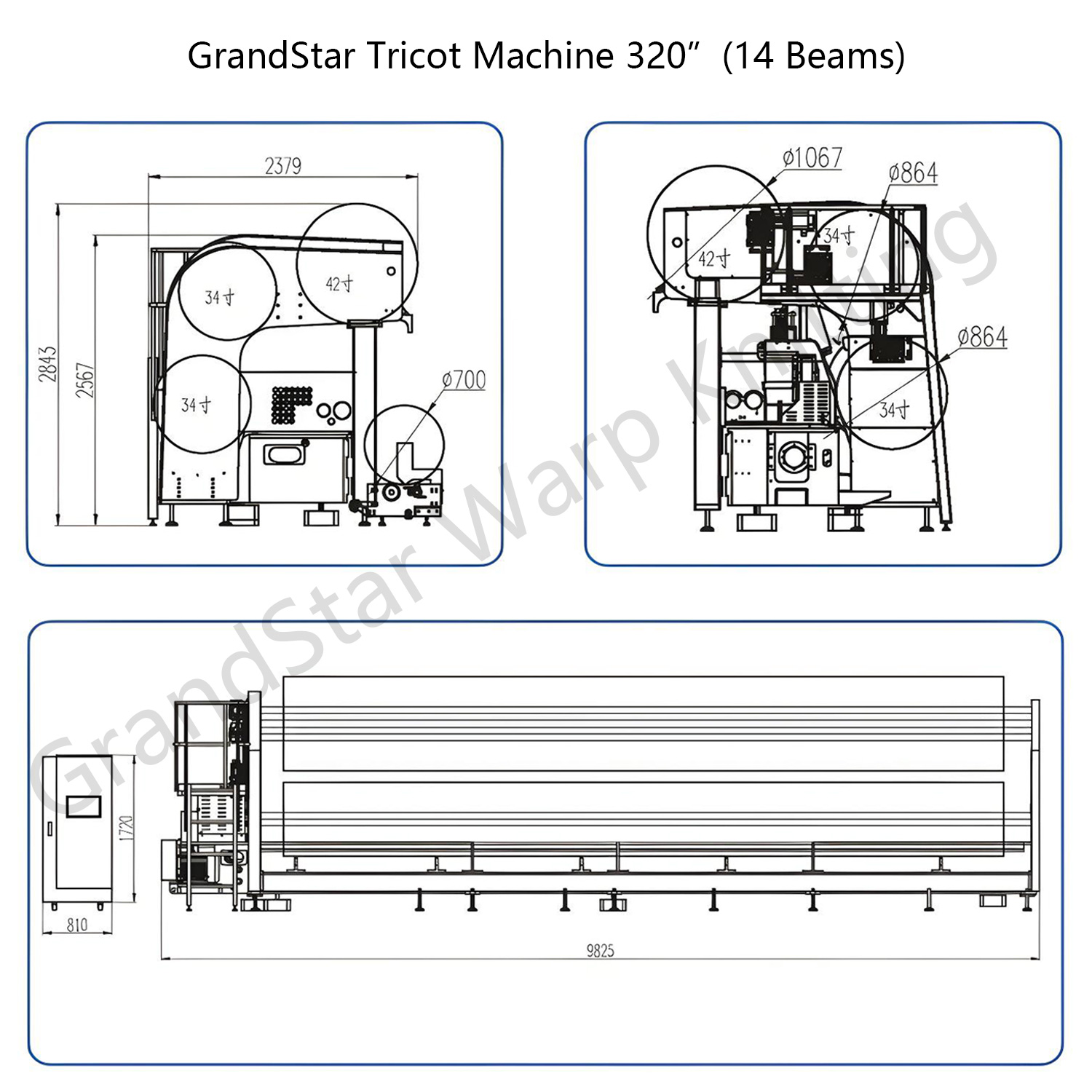

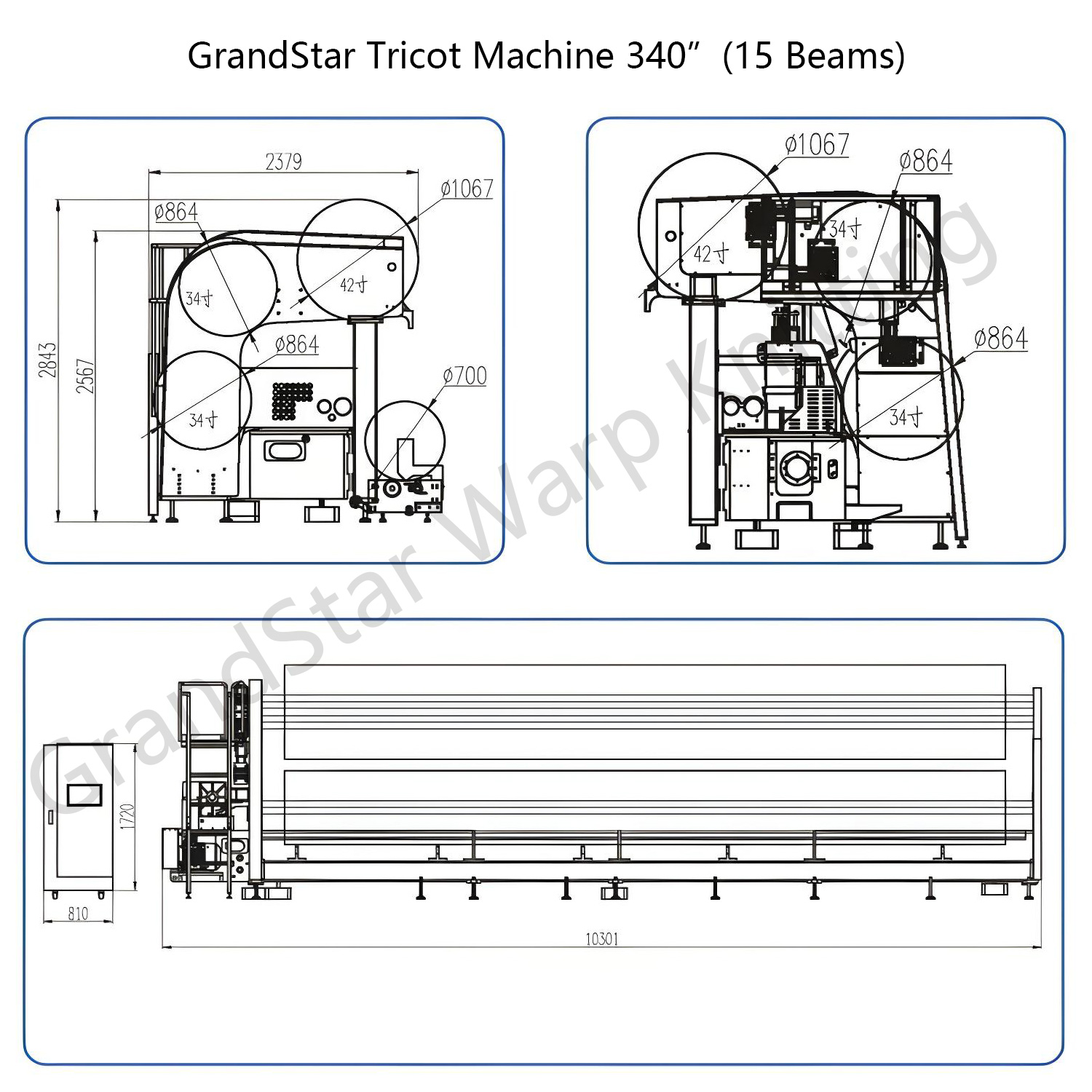

- TECHNICAL DRAWINGS

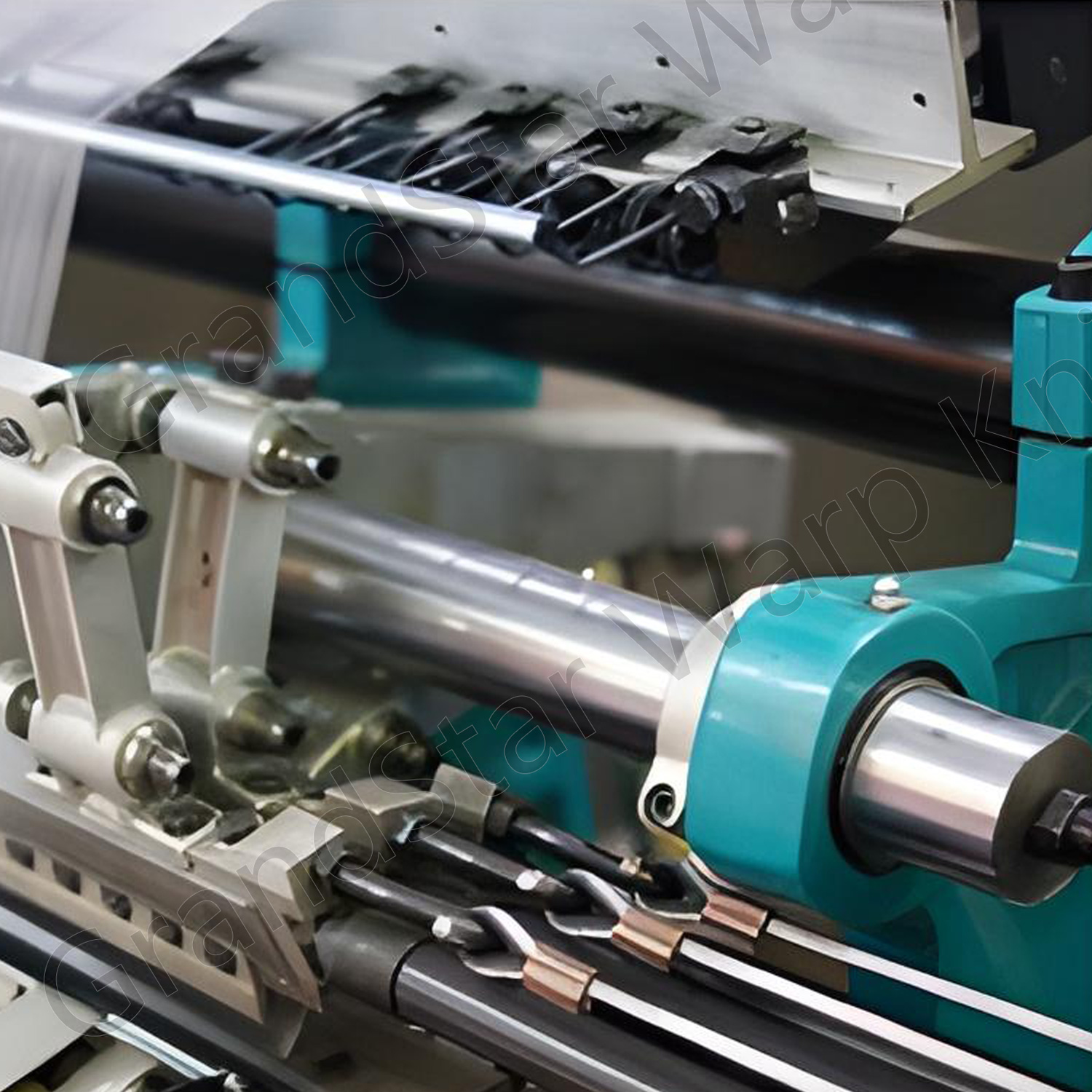

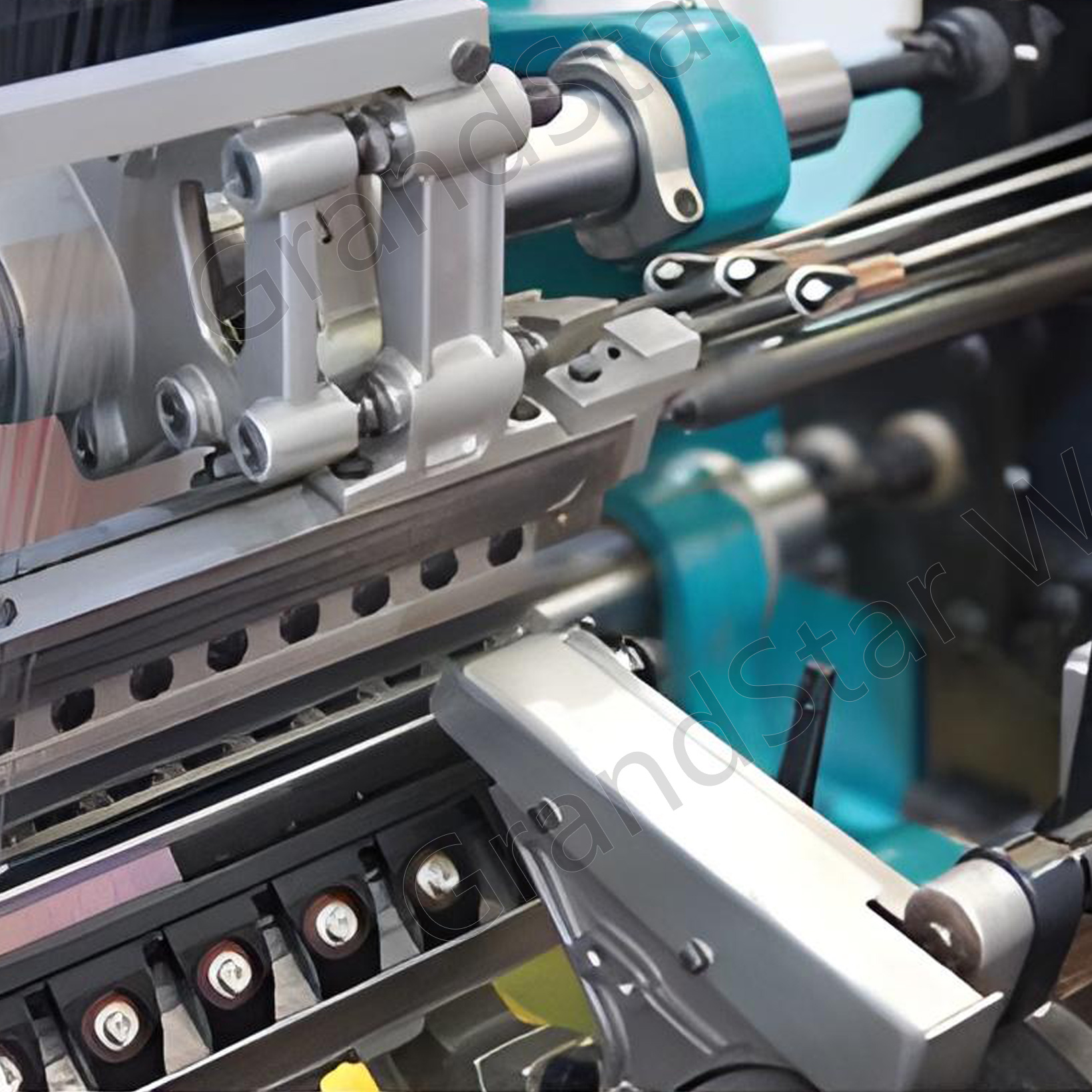

- Advanced Needle System: The machine has an advanced needle bar arrangement and compound needles to facilitate fabric formation tool. This design allows for control of the stitch to give different textures on the fabric produced.

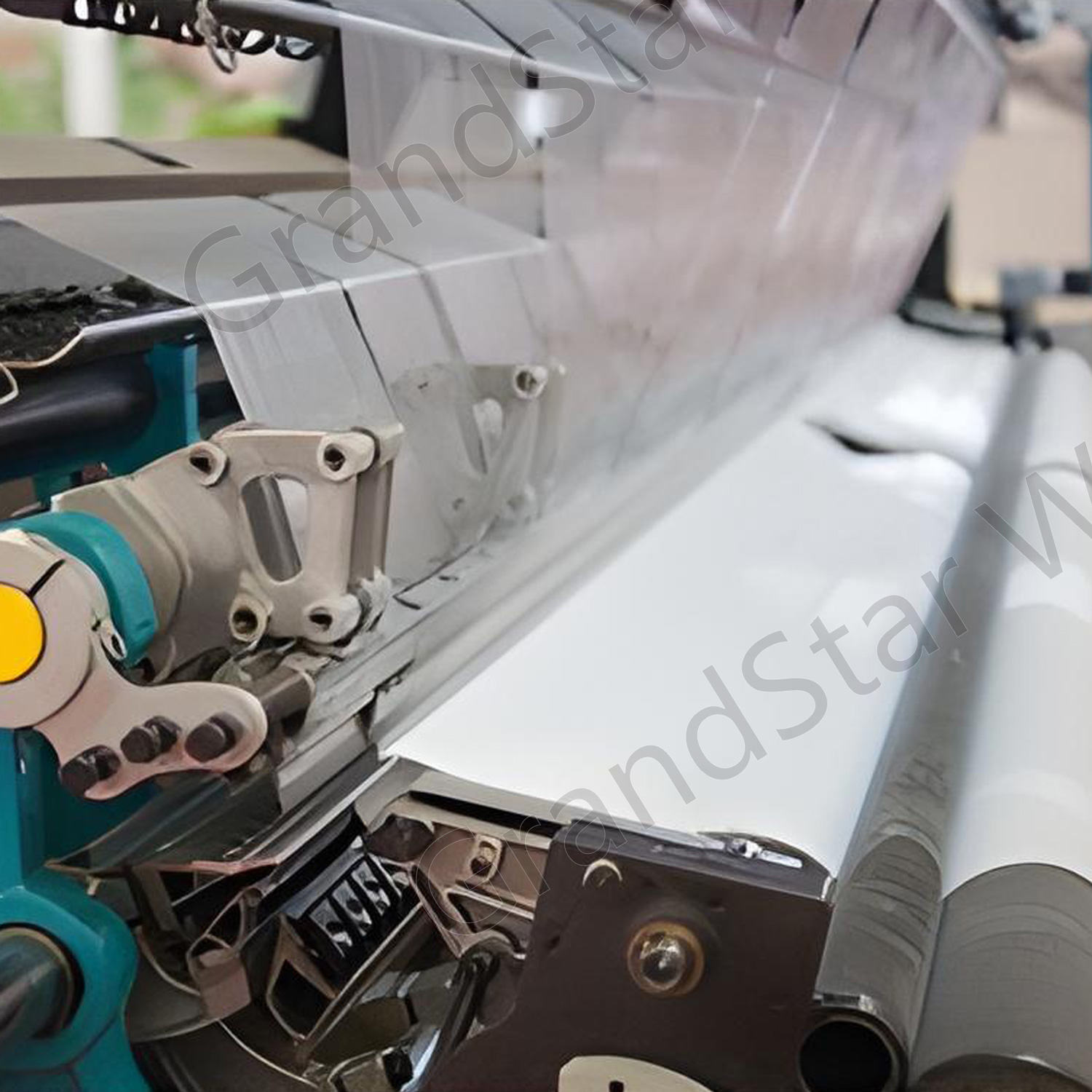

- Guide Bars and Shogging Mechanism: Self-operated with a number of guide bars, Tricot Knitting Machine can offer a high selective control of fabric patterns. The guide bars can slide at distances in order that they are able to create different pattern and surface roughness.

- Fabric Take-Up and Let-Off Systems: The fabric take up is also electronically controlled this way; therefore, the structure has an impressive tension control throughout the manufacturing process. The yarn let-off device is variable with each warp beam in order that the yarn tension is kept accurate throughout the knitting process to avoid the formation of unacceptable fabric contours.

- Integrated Monitoring Systems: Laserstop and camera integration are integrated into the machine for quality monitoring and control since any problem that is identified is addressed instantly. As a result, waste is eliminated, and fabrics are made in equal quality throughout the process.

- GrandStar® COMMAND SYSTEM: The advanced HMI enables simple and accessible manipulation of many machine electronic features and settings. This advanced system improves on the usage and the automation of the machine.

- Energy Efficiency: The advanced technology of speed-regulated drive system allows the machine to enjoy energy efficiency and operational output, making it both environmentally friendly and economically efficient appliance.

Training & Service

Installation & Training

From detailed manuals to local service teams, our support ensures warp knitting machine users maximize efficiency and output worldwide.

Local Service

Our after-sales service spans Turkey, India, Vietnam, Indonesia, and the USA, with plans for expansion. In regions without local teams, real-time online support is the first line of assistance, followed by dispatching engineers for hands-on support if necessary

Application

- Fashion Textiles: Perfect for fabrics used for apparels such as light weight and airiness.

- Technical Textiles: Applied for production of textiles in automotive, medical or construction industries which require material with high level of performance.

- Home Textiles: It is mostly used to in creation of upholstery fabrics, curtains and bedding material with larger patterns.

- Sportswear: Good for its functionality of producing high-performance fabrics that have moisture control in the technical wear segment.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |