Double Raschel Knitting Machine 6 Bars For Spacer

| Double Needle Bar Raschel Machine For Spacer – Warp knitting Machine | |

| Model No. | GS-RD6/1-12 EN |

| Ground Bars | 6 Bars |

| Bars Distance | 1-12 mm |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

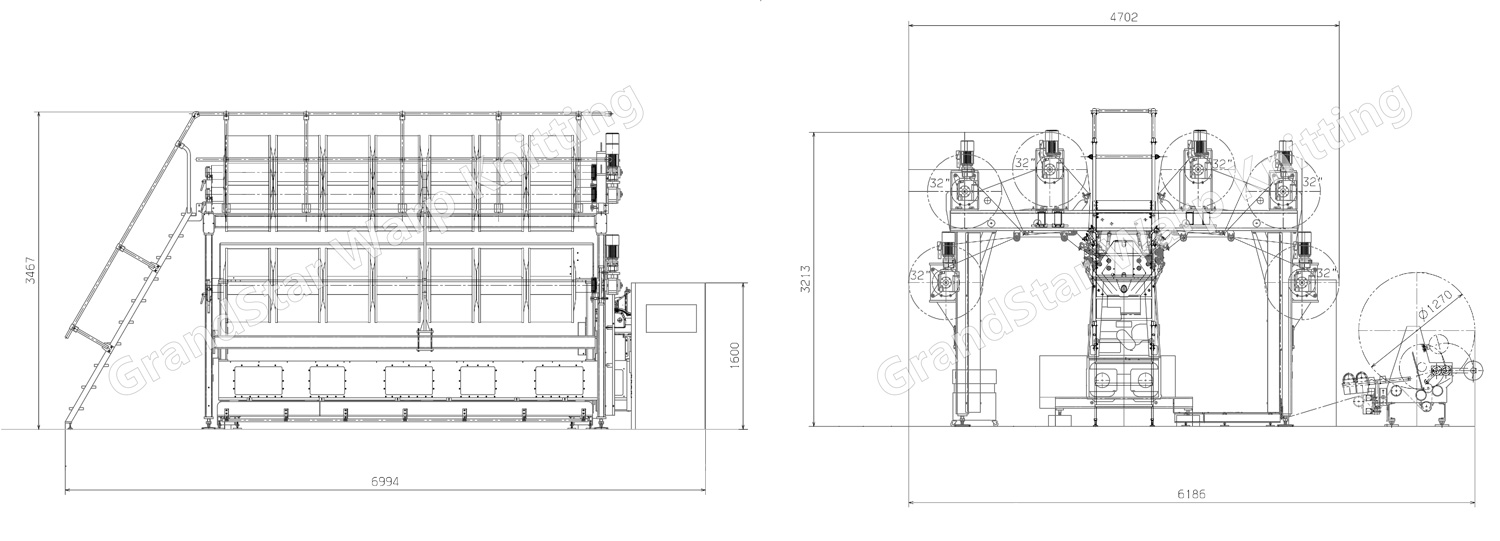

- TECHNICAL DRAWINGS

Working Width / Gauge

- Sizes Available:

- 2540 mm (100”)

- 3505 mm (138”)

- 5334 mm (210”)

- Gauge Options: E18, E22, E24

Comb Bar Distance

- Adjustable from 1–12 mm for precise fabric customization.

- Central trick plate with easy distance readjustment.

Knitting Components

- Needle Bars:

- Two needle bars equipped with latch needle units.

- Comb Bars and Stitch Bars:

- Two knock-over comb bars and two movable stitch comb bars.

- Ground Bars:

- Six ground bars, including GB3 and GB4 for stitch forming on both needle bars.

- Optional: Individual needle bars for specific production needs.

Support Systems

Warp Beam Support

- Six warp beams with a capacity of 812 mm (32″) in a free-standing design.

Fabric Take-Up

- Electronically regulated, gear motor-driven system with four rollers for consistent fabric winding.

Batching Device

- Includes a separate rolling device for easy fabric collection.

Control Systems

GrandStar® Command System

- A user-friendly interface that enables operators to configure, control, and adjust the machine’s electronic features efficiently.

Yarn Let-Off Device

- Each warp beam is equipped with an electronically controlled yarn let-off drive for consistent tension and smooth operation.

Pattern Drive

- EN-Drive system with seven electronic guide bar drives.

- Shog Distance: Ground (18 mm), Pile (25 mm).

- Optional: EL electronic guide bar drive with shogging up to 150 mm.

Electrical Requirements

- Power Specifications:

- Connected Load: 7.5 KW

- Voltage: 380V±10% (three-phase power supply)

- Wiring Needs:

- Main Power Cord: ≥4mm² three-phase four-core power cord

- Ground Wire: ≥6mm² for enhanced safety

Oil Supply and Maintenance

- Heating and cooling systems utilize a circulating air heat exchanger.

- Equipped with a dirt-monitoring filter for cleaner operations and reduced maintenance.

Operating Conditions

- Temperature: 25℃±3℃

- Humidity: 65%±10%

- Floor Pressure: 2000–4000 KG/㎡

Training & Service

Installation & Training

Technical support is a cornerstone of our warp knitting machine services. To ensure our customers maximize the performance of their machines, we provide comprehensive training programs in multiple formats.

Local Service

Our commitment to exceptional after-sales service extends to Turkey, India, Vietnam, Indonesia, and the USA, with plans to expand our local service teams to additional countries in the near future.

Application

- Automotive Industry: Spacer fabrics are used in car seat covers, headliners, and interior upholstery due to their cushioning properties.

- Medical Applications: Common in mattresses, bandages, and other breathable and hygienic materials.

- Furniture: Used for ergonomic and comfortable seating solutions.

- Geotextiles: Fabrics for construction, landscaping, and erosion control.

- Filtration: Used in water, air, and industrial filtration systems.

- Protective Clothing: Lightweight and durable textiles for industrial safety apparel.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |