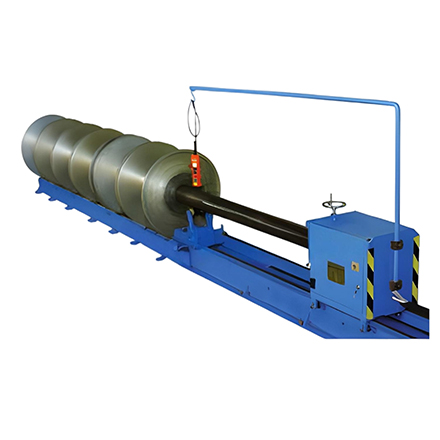

Beam Auto-Installation

| Category | Facilitate Machines | Beam Auto-Installation |

| Model No. | Beam Auto-Installation |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

· Automated Beam Loading

One of the components is the possibility to position the warp beams automatically and do not require manual adjustment. Reduces the physical demand on the operators thereby making their operations safer.

· Precision Alignment

Contemporary sensors and alignment systems are employed to guarantee that the warp beams are well aligned. Ensures equal distribution of the forces across the width of the fabric necessary for fabric production of standard quality.

· Fast and Efficient Process

Eases the process of conducting beam installation and makes the overall setup time a lot shorter compared to previous methods. Reduces aggregate time lost through production stoppage hence increases total machine efficiency.

· Integration with different sizes of beams

Arranged to contour beam diameter and weight, which provide capacity for various fabric production needs. Conveys warp beam sizes up to 6 × 812 mm (32”) independent of the frame.

· Operator-Friendly Interface

Combined with the GrandStar® Command System, providing the operating personnel with simple controls to operate and observe the beam installation. A set of instructions aids the operator, so the installation process runs without mistakes and errors.

Application

- alignment and tensioning automatically.

- Consistency: It helps to control the standard of fabric manufacture by preserving the right perpendicular and tension to the beams.

- Reduced Downtime: Reduces cycle time during changeover enhancing the availability of the machines.

- Labor Efficiency: Reduces the dependency level on manual labor while performing the operation so that the operators can work on the other aspects of production.

- Safety Assurance: Reduces the risks resulting from holding and turning large warp beams by hand.