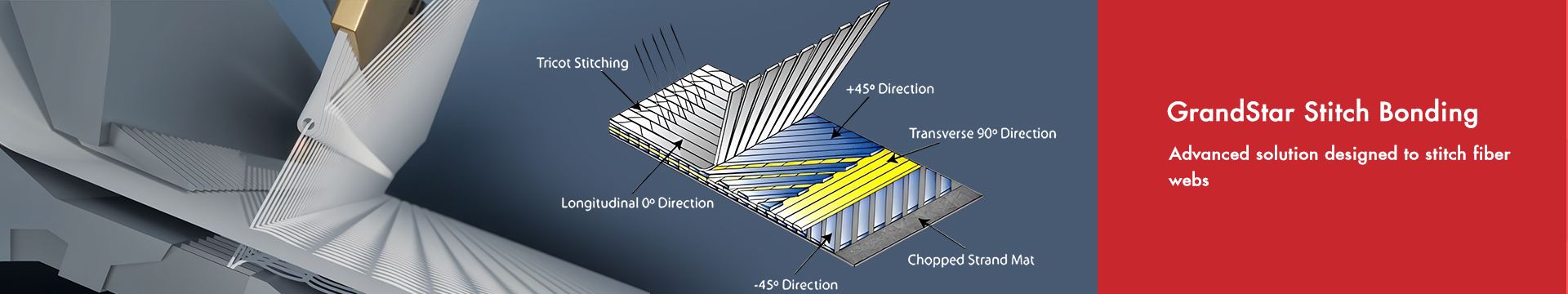

FB Stitch-Bonding Machine

| Stitch Bonding Machine For FB Fiber Web – Waro Knitting Machine | |

| Model No. | GS-FB1/FB2 |

| Bars Number | 1 and 2 Bars |

| Beam Size | 30inch EBC |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

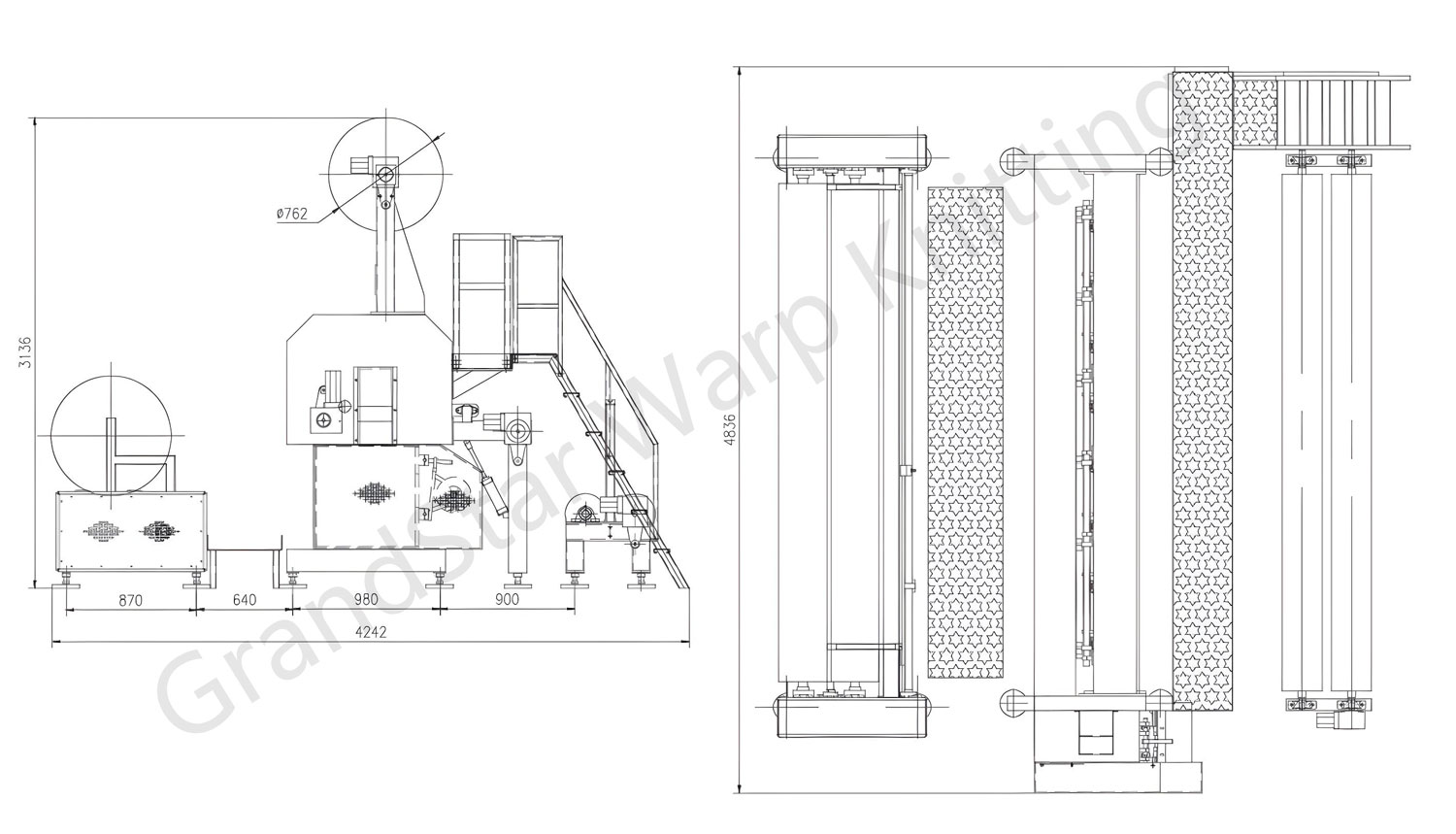

- TECHNICAL DATA

- TECHNICAL DRAWINGS

Working Width Options

- 2000mm, 2800mm, 3600mm, 4400mm, 4800mm, 5400mm, 6000mm

Gauge Options

- F7, F12, F14, F16, F18, F20, F22

Bars/Knitting Elements

- Compound needle bar

- Closing wire bar

- Knock-over sinker bar

- Supporting bar

- Counter-retaining bar

- 1 or 2 ground guide bars

Pattern Drive-N

- N-drive with a pattern disc

- Integrated tempi change gear drive

- Single pattern disc for enhanced functionality

Warp Beam Support

- 1 or 2 warp beam positions for sectional use

- Maximum flange diameter: 30

Yarn Let-Off Device

- Electronically controlled yarn let-off drive

- Geared motor with a frequency converter for precise control

Yarn Stop Motion

- Optional electronically controlled system

Fabric Take-Up

- Electronically controlled fabric take-up system

- Driven by a geared motor with a frequency converter

Batching Device (Standalone)

- Friction drive with a pressure roller

- Maximum batch diameter: 914mm (36 inches)

- Geared motor with integrated frequency converter

Advanced Motion Control

- Machine Control: Managed by an integrated computer system to oversee main drive, yarn feeding, and fabric take-up.

- Operator Interface: Intuitive touch screen for real-time production data display.

Electrical Equipment

- Speed-regulated drive with power-failure safety features.

- Single speed control for primary functions via frequency converter.

- Main Motor Power:

- 2000mm–4400mm width: 13 KW

- 4400mm–6000mm width: 18 KW

Training & Service

Installation & Training

Technical support is a cornerstone of our warp knitting machine services. These include detailed professional manuals, online guidance, instructional video libraries, and on-site training sessions tailored to specific customer needs.

Local Service

In regions without local service teams, we offer real-time online support as the first line of assistance. Should further intervention be required, we dispatch engineers from the nearest service hub directly to the customer’s facility to provide hands-on support.

Application

The Stitch-Bonding Machine is ideal for producing the following:

- Stitch-Bonded Fabrics: Durable and versatile textiles for industrial and consumer applications.

- Medical Bandages: High-quality fabric designed for medical and healthcare use.

- Clothing Interlining: Stable and durable interlining for garment construction.

- Curtain Fabric: Precisely stitched fabrics for interior design and furnishing purposes.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |