Direct warper for filament yarn

| Direct Warper for filament yarn – Warping Machine / Warp Preparation | |

| Model No. | GS-DS 50-40 DNC |

| Application | Filament Yarn |

| Beam Size | Max 50*40″ |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

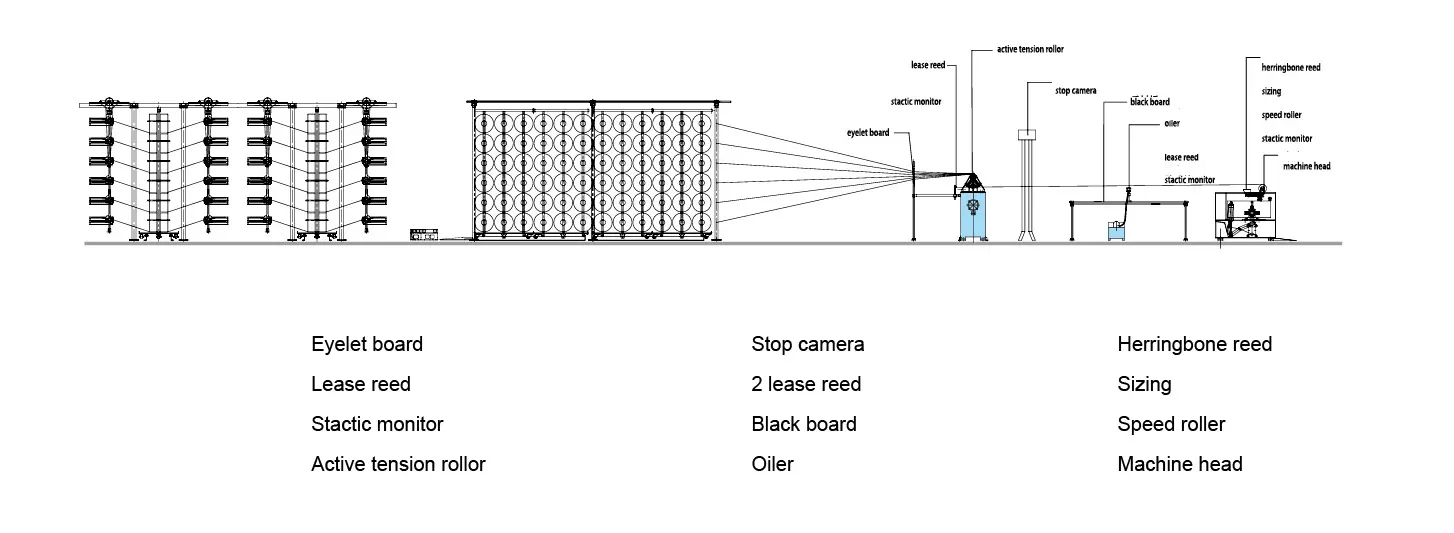

Key Features and Technical Specifications

Model Variants:

- GS-DS 50/32 DNC

- GS-DS 50/40 DNC

Technical Facts:

| Feature | GS-DS 50/32 DNC | GS-DS 50/40 DNC |

|---|---|---|

| Maximum Speed | 1200 m/min. | 1200 m/min. |

| Maximum Yarn Tension | 540N | 540N |

| Pressure Roller | Available | Available |

| Levelling Roller Unit | Yes | Yes |

| Tandem Warping Device | Available | Available |

| High-Tenacity Device | Available | Available |

| Maximum Yarn Tension (High-Tenacity) | 1600N | 1600N |

| Maximum Speed (High-Tenacity) | 600 m/min. | 600 m/min. |

Training & Service

Installation & Training

Our technical support covers warp knitting machine training via manuals, videos, online resources, and on-site programs in over 20 countries, with teams in five key regions.

Local Service

Grandstar ensures machine longevity with on-site services across Turkey, India, Vietnam, Indonesia, and the USA, combined with professional maintenance routines.

Application

- Filament Yarn Processing:

This machine is perfect for direct warping of filament yarns, including synthetic, polyester, and nylon yarns, ensuring precise tension and consistent quality. - High-Tenacity Yarn Warping:

With its high-tenacity device, it can handle yarns with up to 1600N tension, making it suitable for heavy-duty textile applications such as industrial fabrics and technical textiles. - Textile Weaving Preparation:

It prepares warp beams efficiently for weaving operations, offering uniform tension and alignment critical for high-quality fabric production. - Specialty Fabrics Production:

The tandem warping device allows for processing specialty yarns, enabling the production of customized fabrics for industries such as automotive, aerospace, and home furnishings.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |