Forged Beam For Warp Knittin

| Forged Beam For WarpKnitting Machine | |

| Model No. | 21×21 30×21 41×42 30×42 |

| Application | Filament Yarn |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Forged Warping Beams – The Key to Superior Warp Knitting Performance

In the highly competitive textile industry, achieving precision, durability, and efficiency in warp knitting operations is essential. Forged warping beams have emerged as the preferred choice over conventional alternatives due to their unparalleled strength, superior yarn tension control, and contribution to fabric quality. Whether for high-speed production or specialty fabric applications, investing in forged warping beams can significantly enhance the overall knitting process.

Why Forged Warping Beams Matter in Warp Knitting Machines

Warp knitting relies on precise yarn handling, and the quality of the warping beam directly influences the efficiency and consistency of the entire process. Unlike standard cast or welded beams, forged warping beams offer exceptional durability and tension stability, minimizing variations in fabric production. This not only improves fabric quality but also extends machine lifespan and reduces operational costs.

Key Advantages of Forged Warping Beams Over Competitors

1. Unmatched Strength and Durability

Forged warping beams are produced through an advanced forging process that refines their internal grain structure, making them stronger and more resilient than cast or welded alternatives. This process eliminates weak points, ensuring the beams can withstand extreme yarn tension and continuous high-speed operation without deformation or failure.

2. Superior Yarn Tension Control for Precision Knitting

Inconsistent yarn tension leads to defects in fabric structure. Forged warping beams provide precise and uniform tension distribution, ensuring flawless fabric formation. Their high structural integrity minimizes tension fluctuations, allowing warp knitting machines to operate with greater consistency and efficiency.

3. Enhanced Productivity and Reduced Downtime

Unlike lower-quality beams that require frequent adjustments and replacements, forged warping beams significantly reduce machine downtime. Their superior mechanical properties ensure smooth operation, leading to higher output rates and optimized production cycles, giving textile manufacturers a competitive edge.

4. Exceptional Fabric Quality with Fewer Defects

Fabric quality is directly influenced by warp yarn stability. Forged warping beams maintain consistent yarn tension across the entire knitting width, preventing defects such as uneven stitches or distortions. This results in premium-quality textiles that meet stringent industry standards.

5. Versatility for Various Yarn Types and Applications

Whether working with natural fibers, synthetic yarns, or technical textiles, forged warping beams provide unmatched adaptability. Their robust construction supports diverse yarn properties, making them an ideal choice for manufacturers looking to expand their product offerings without compromising quality.

Why Choose Forged Warping Beams for Your Warp Knitting Machines?

For textile manufacturers aiming to maximize efficiency, reduce maintenance costs, and improve fabric quality, forged warping beams are the ultimate investment. Their combination of strength, precision, and longevity makes them an essential component for high-performance warp knitting.

Upgrade your warp knitting capabilities today with forged warping beams and experience the difference in production efficiency and fabric excellence.

Application

Forged Beam: Applications and Key Features

High-Strength Construction

Forged beams are made from premium-grade materials such as cast aluminum or steel, ensuring exceptional durability and wear resistance. This robust construction extends the beam’s lifespan, even under high-load conditions.

Precision Engineering

Designed with a perfectly balanced structure, forged beams minimize vibration and ensure consistent warp tension. This precision enhances fabric quality and optimizes machine performance in high-speed operations.

Lightweight Design

Despite its strength, the forged beam remains lightweight. This feature simplifies handling, reduces machine load, and improves overall efficiency in textile production.

Corrosion Resistance

Special coatings or treatments protect the beam from humidity and chemicals, preventing corrosion and ensuring long-term reliability in various textile environments.

Standard and Custom Sizes

Available in a range of diameters and working widths, forged beams cater to diverse machine specifications, providing seamless integration across different textile processes.

Machine Compatibility

Engineered for versatility, forged beams are compatible with warp knitting, weaving, and warping machines, enabling smooth and efficient operation across multiple textile applications.

Applications of Forged Beam

Warp Knitting Machines

Used to maintain consistent tension and alignment of warp yarns, ensuring high-quality fabric production.

Weaving Machines

Facilitates the smooth unwinding of warp yarns in weaving applications, suitable for technical and decorative fabrics.

Textile Manufacturing

Essential for apparel, automotive textiles, home furnishings, and industrial fabric production, supporting high-efficiency output.

Technical Textiles

Ideal for heavy-duty yarn applications such as filtration fabrics, protective gear, and geotextiles, ensuring strength and stability.

High-Speed Operations

Designed for modern, high-speed machines, forged beams enhance production stability and reduce downtime, increasing manufacturing efficiency.

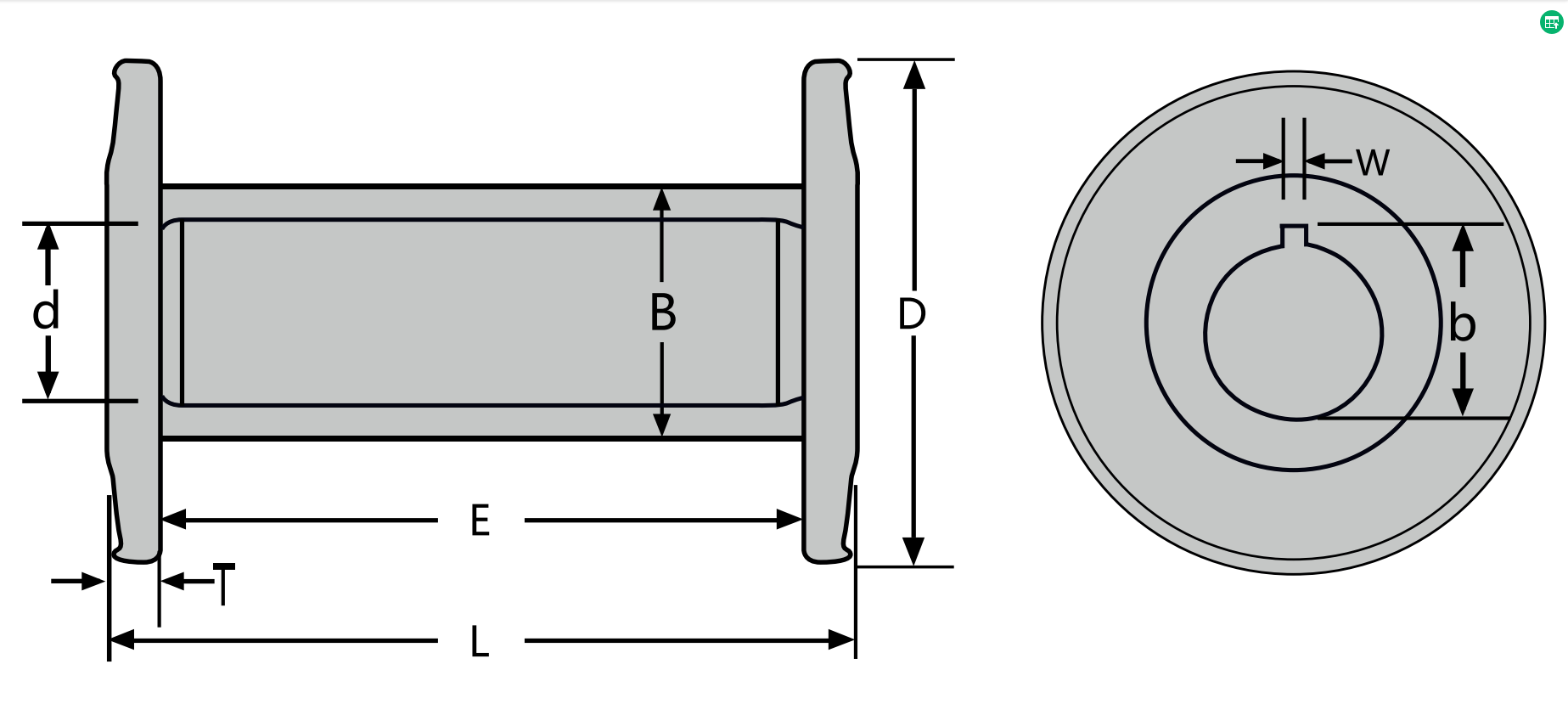

Product Specification Table

| Item | Specification (DxL Inch) | DXE | L (mm) | B (mm) | T (mm) | d (mm) | W (mm) | b (mm) | Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|

| J-001 | 8″x8″ | 200×165 | 203 | Φ100 | |||||

| J-002 | 10″x8″ | 254×174 | 204 | Φ100 | 15 | Φ70.5 | 14 | 75 | 4.4 |

| J-003 | 14″x14″ | 355×317 | 355 | Φ110 | 19 | Φ70.5 | 16 | 78 | 10.0 |

| J-004 | 17″x14″ | 432×300 | 355 | Φ118 | 27.5 | Φ70.5 | 20 | 77 | 17.0 |

| J-005 | 18″x14″ | 450×300 | 360 | Φ150 | 30 | Φ90.0 | 16 | 98 | 21.0 |

| J-006 | 21″x21″ | 535×470 | 540 | Φ200 | 35 | Φ152.7 | 20 | 161 | 38.0 |

| J-007 | 26″x21″ | 660×470 | 540 | Φ260 | 35 | Φ152.7 | 20 | 161 | 68.0 |

| J-008 | 30″x21″ | 762×470 | 540 | Φ260 | 35 | Φ152.7 | 20 | 161 | 72.0 |

| J-009 | 30″x21″ | 762×470 | 540 | Φ300 | 35 | Φ152.7 | 20 | 161 | 88.0 |

| J-011 | 31.5″x21″ | 800×470 | 540 | Φ300 | 35 | Φ152.7 | 20 | 161 | 95.0 |

| J-012 | 34.5″x21″ | 880×470 | 540 | Φ300 | 35 | Φ152.7 | 20 | 161 | 105.0 |

| J-013 | 40″x21″ | 1000×470 | 540 | Φ300 | 35 | Φ152.7 | 20 | 161 | 130.0 |

| J-014 | 42″x21″ | 1060×470 | 540 | Φ300 | 35 | Φ152.7 | 20 | 161 | |

| J-015 | 21″x42″ | 535×992 | 1062 | Φ300 | 35 | Φ152.7 | 20 | 161 | 50.0 |

| J-016 | 30″x42″ | 762×977 | 1066 | Φ300 | 44.5 | Φ152.7 | 20 | 161 | 124 |

| J-017 | 40″x42″ | 1000×977 | 1066 | Φ300 | 44.5 | Φ152.7 | 20 | 161 | 170 |

| J-018 | 31.5″x46.5″ | 800×1091 | 1180 | Φ300 | 44.5 | Φ152.7 | 20 | 161 | 130 |

| J-019 | 40″x46.5″ | 1000×1091 | 1180 | Φ300 | 44.5 | Φ152.7 | 20 | 161 | 180 |

| J-020 | 21″x21″ | 532×482 | 540 | Φ200 | 29 | Φ152.7 | 20 | 161 | 58 |

| J-021 | 21″x21″ | 532×490 | 540 | Φ200 | 25 | Φ152.7 | 20 | 161 | 78 |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |