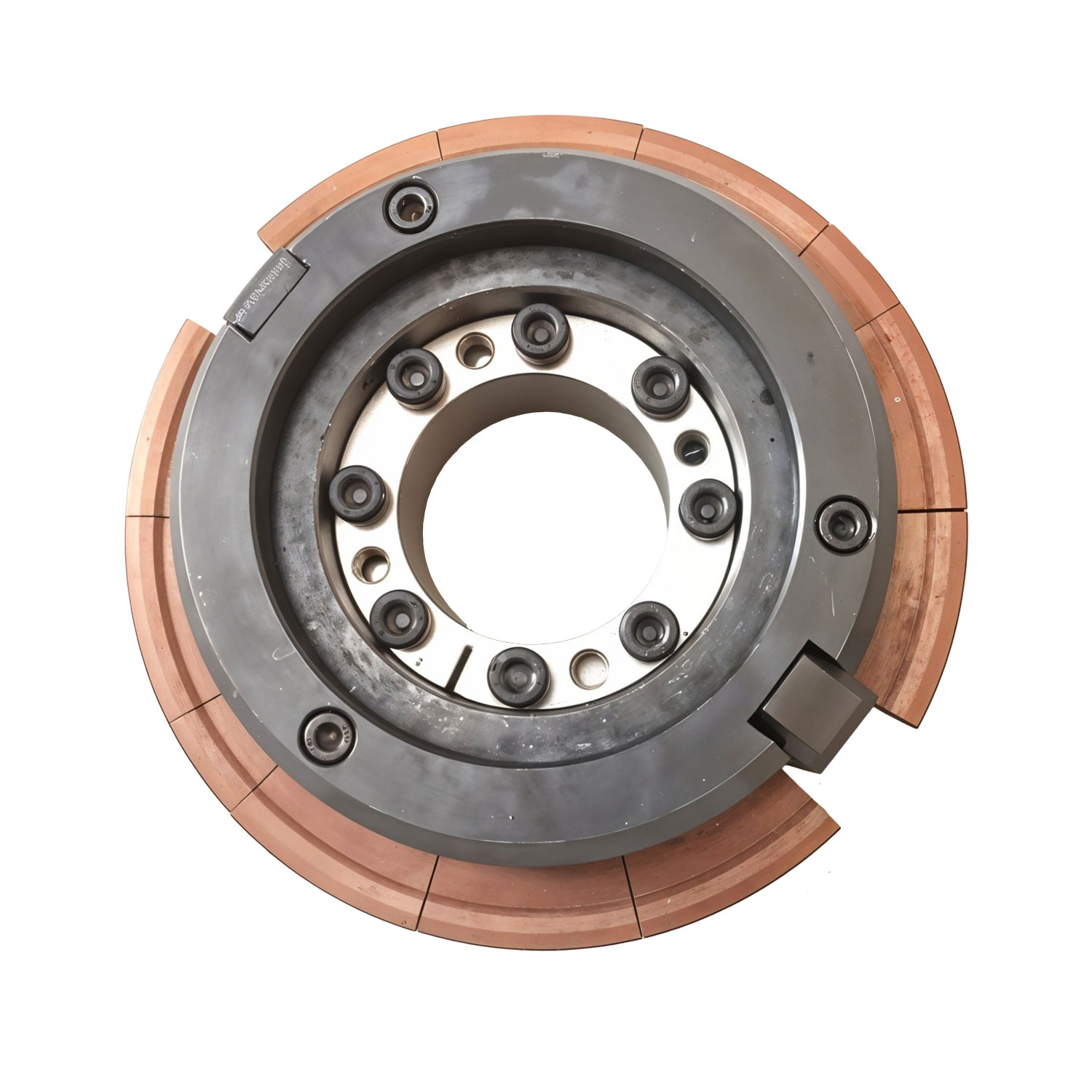

Beam Chuck

| Beam Chuck For Warping Machine | |

| Model No. | Beam Chuck |

| Application | For Beam Rolling |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Beam Chuck: Precision Engineering for Superior Warping Performance

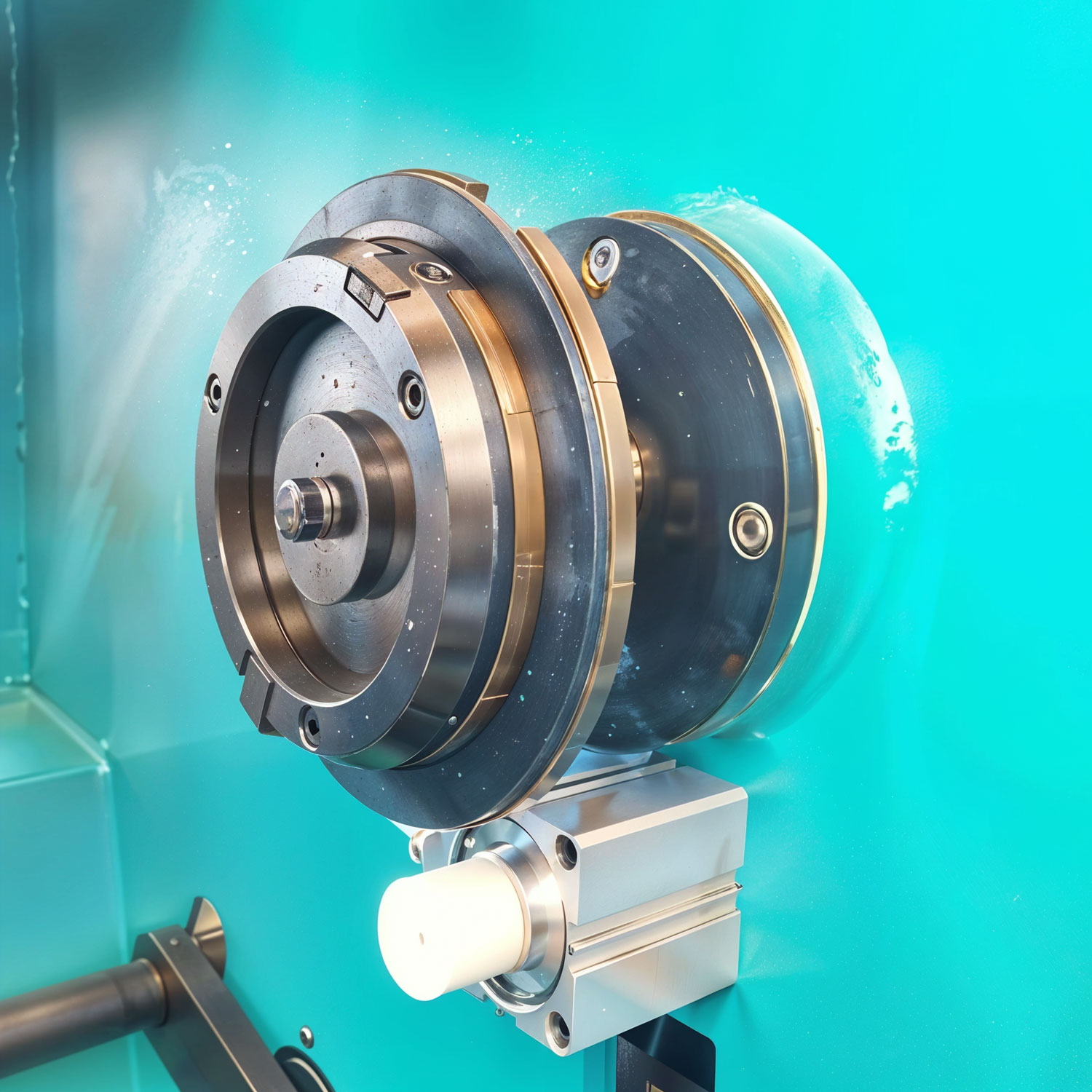

In the high-speed, high-precision world of warp knitting, the Beam Chuck plays a crucial role in ensuring smooth and efficient warping operations. Designed to support the beam on the warping machine, it is engineered to accommodate the demanding conditions of modern textile production.

Unmatched Stability and Precision

Unlike conventional chucks, our Beam Chuck is built for exceptional stability and precision engagement with the warping control system. This ensures seamless synchronization between the beam and yarn tension control, leading to consistent warping accuracy even at high operational speeds.

Heavy-Duty Load Bearing for Longevity

One of its standout advantages is its ability to support heavy beam heads with remarkable load-bearing capacity, reducing mechanical stress and extending machine lifespan. Additionally, its high-precision engagement mechanism optimizes the control of yarn tension and warping movement, minimizing variations that can lead to defects in fabric production.

Superior Performance Over Traditional Beam Chucks

- Enhanced operational efficiency – Ensures smooth and uninterrupted warping at high speeds.

- Lower maintenance costs – Engineered for durability, reducing wear and tear.

- Increased production stability – Reduces vibration and enhances synchronization.

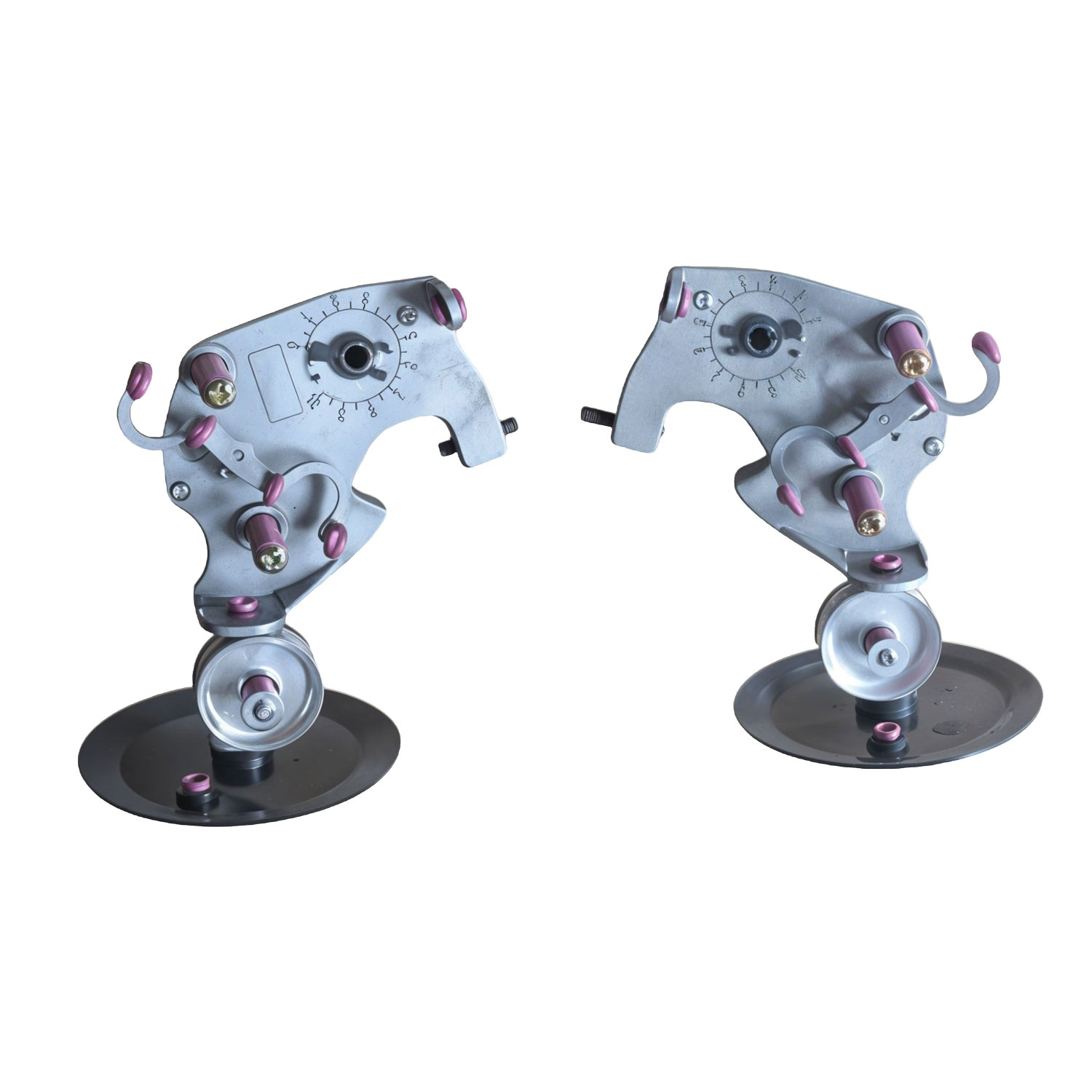

- Versatile application – Handles both delicate yarns and heavy-duty beams with ease.

Elevate Your Warp Knitting Operations

By integrating our high-performance Beam Chuck, warp knitting manufacturers can achieve smoother, faster, and more consistent production, setting new benchmarks in fabric quality and machine efficiency.

Application

- Manufacturing Machinery: Used in conveyors, assembly lines, and other manufacturing systems to ensure smooth rotation and functionality.

- Automotive Industry: Essential in vehicle engines, gearboxes, and transmission systems for efficient power transmission.

- Pumps and Compressors: Used in pumps and compressor systems, helping transfer force between the motor and rotating components.

- Textile Machinery: Crucial in spinning, weaving, and knitting machines where precise rotation is needed.

- Agricultural Equipment: Found in equipment such as harvesters, tractors, and plows to ensure efficient power transmission.