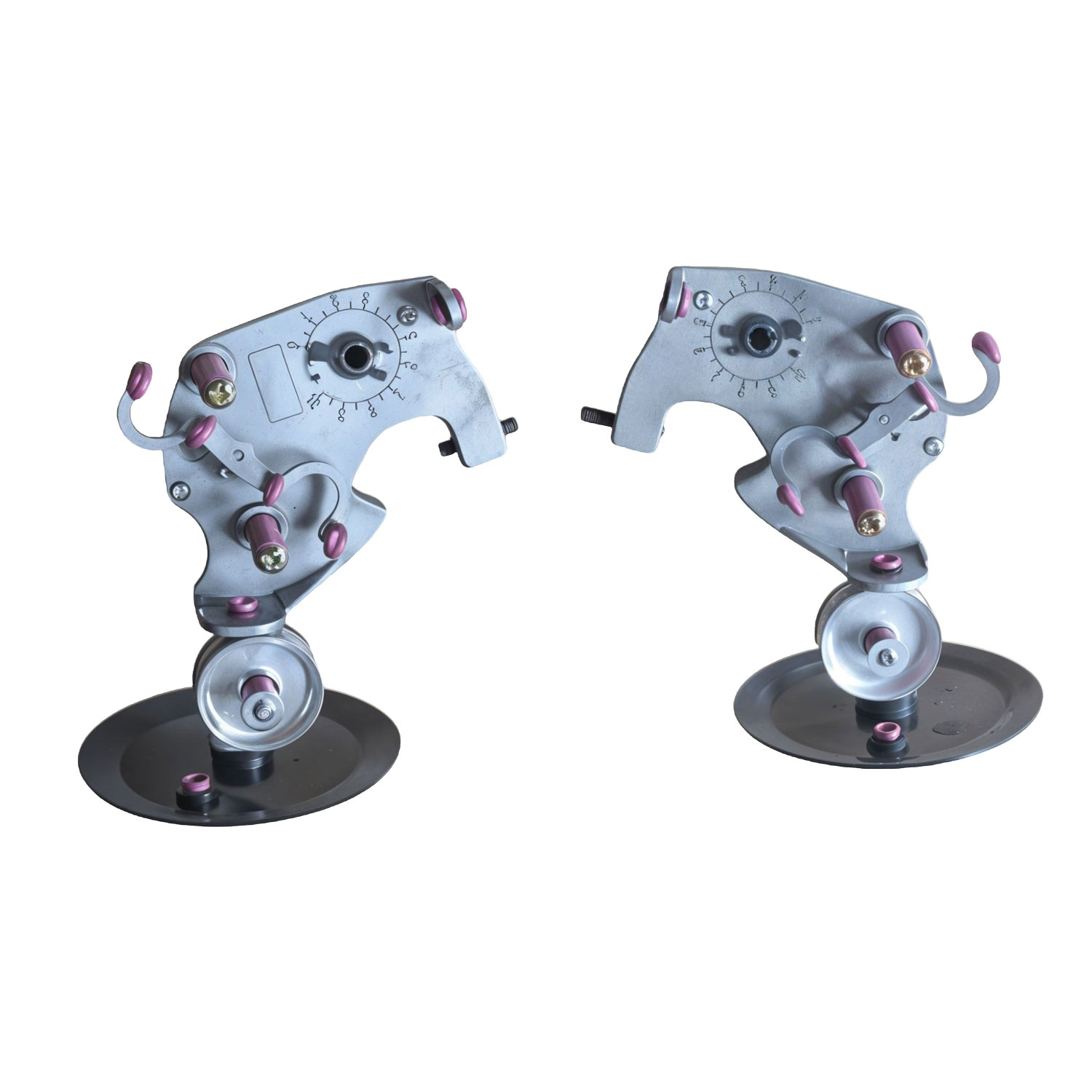

Warping Static Eliminator

| Warping Static Eliminator For Warping Machine | |

| Model No. | Static Eliminator |

| Application | For Detecting Yarn Drop / Break |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Warping Static Eliminator: Enhancing Efficiency and Yarn Quality in Warping Processes

In modern warp knitting production, static electricity is a common yet often overlooked challenge, especially when dealing with synthetic fiber filaments. The Warping Static Eliminator is an advanced solution designed to eliminate static charges generated by friction, ensuring smooth, uninterrupted operation and significantly improving yarn handling efficiency.

Unmatched Performance in Eliminating Static Electricity

Unlike conventional methods, which may provide inconsistent results, our Warping Static Eliminator utilizes a high-voltage discharge principle to deliver precise and efficient static neutralization. By applying a high voltage to the discharge electrode, it polarizes the surrounding air within a 30–50mm range, generating positive and negative ions that actively neutralize the static charge on the filaments. This process prevents yarn kinking, pilling, and breakage, ensuring superior yarn quality and reducing material waste.

Optimized Placement for Maximum Effectiveness

The versatility of our Warping Static Eliminator sets it apart from standard industry solutions. It can be strategically positioned in key areas of the warping machine where static electricity is most likely to affect performance, such as:

- Above the fixed-width reed bracket – Ensuring stable yarn alignment.

- Near the tension device – Preventing uneven tension caused by static buildup.

- Warp break stop device – Enhancing real-time monitoring and reducing breakage.

- Rear reed and length measuring roller – Improving accuracy and consistency in warp measurement.

Advantages Over Competitors

🔹 Higher Efficiency

Our static eliminator achieves faster and more thorough charge neutralization than conventional systems, reducing yarn handling disruptions.

🔹 Enhanced Production Stability

By preventing yarn-related defects, it significantly lowers machine downtime and enhances overall productivity.

🔹 Superior Adaptability

Its flexible placement options allow seamless integration into existing warping setups, offering greater convenience and operational efficiency.

🔹 Long-Lasting Reliability

Engineered with premium materials and cutting-edge technology, our static eliminator ensures consistent performance with minimal maintenance.

Upgrade Your Warping Process Today!

By choosing our Warping Static Eliminator, warp knitting manufacturers gain a competitive edge in production efficiency, yarn quality, and cost-effectiveness. Upgrade your warping process today and experience a seamless, high-performance operation!

Application

- Electronics Manufacturing: Crucial for identifying areas of static electricity that can harm intricate circuits or equipment during construction or during the performance of tests.

- Pharmaceuticals: Assists in assuring that static electricity does not cause any problems with either the production of drug products or packaging.

- Textile Industry: Ideal for observing static in manufacturing processes of textiles to avoiding formation of defects in the fabrics or harm to equipment.

- Packaging: Essential especially when the packaging material is sensitive to static such as foodstuff and even in microchippers.

- Clean Rooms: Makes sure that the flow of static electricity is well controlled in clean places, which can affect product performance or contaminate it in case of any little charge.