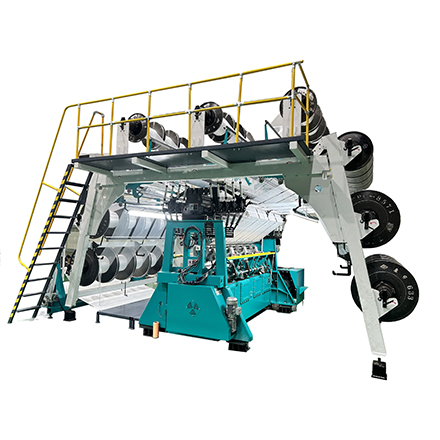

Jacquard Double Needle Bar Raschel 7/1

| Jacquard Double Needle Bar Raschel Machine – Warp Knitting Machine | |

| Model No. | GS-RDPJ 7/1 (EL) |

| Ground Bars | 6 Bars |

| Jacquard Bars | 2 Bar (1 Group) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

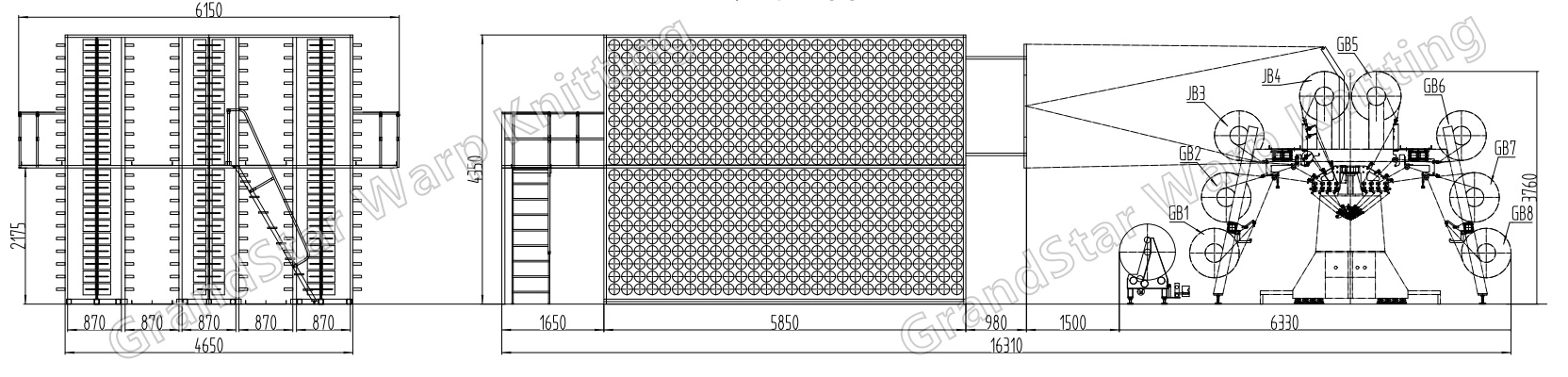

- TECHNICAL DRAWINGS

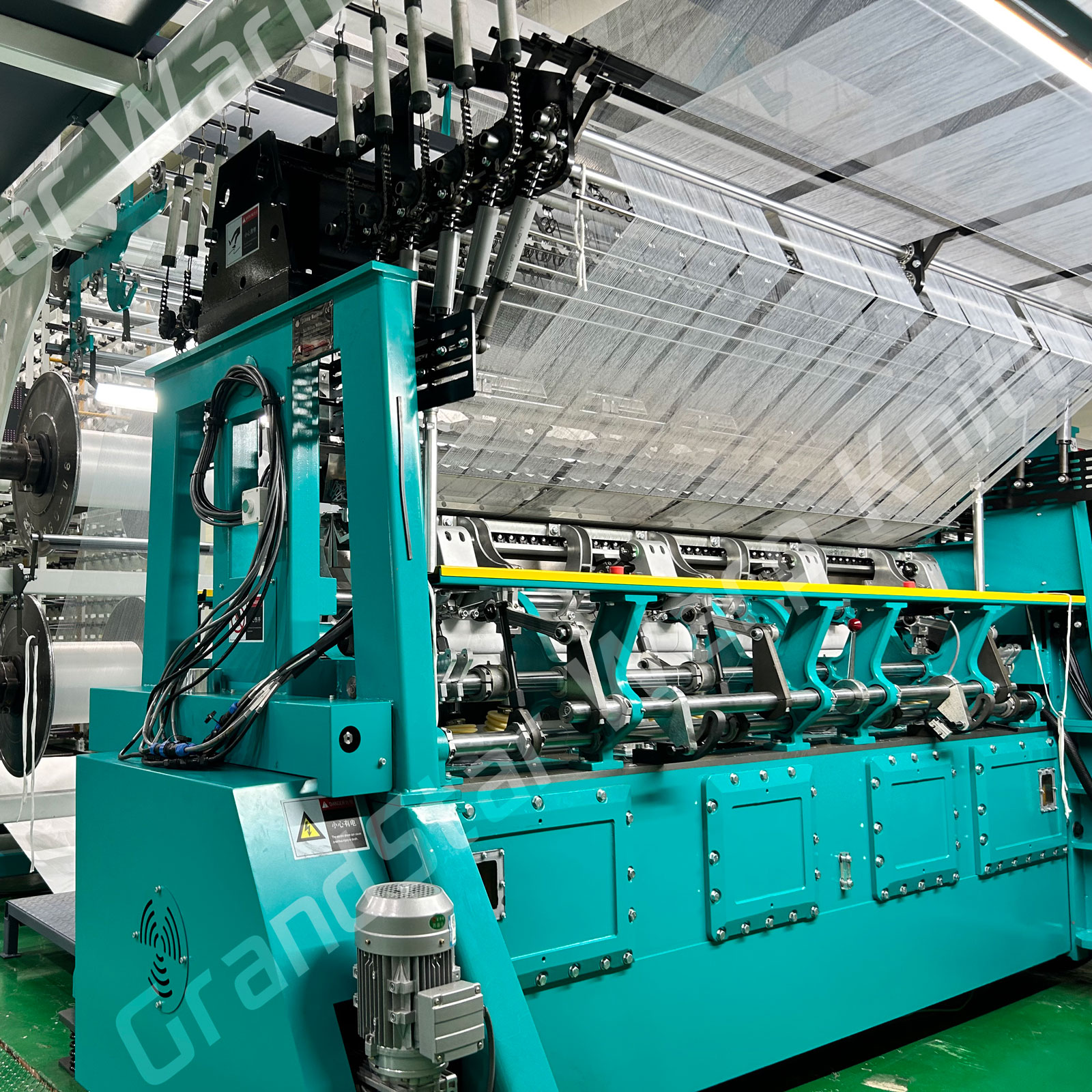

- Working Width / Gauge: 3454 mm (136″), available in E18, E22, E24, E28 gauges.

- Knock-over Comb Bar Distance: 2–12 mm, continuously adjustable. Central trick plate distance can be readjusted.

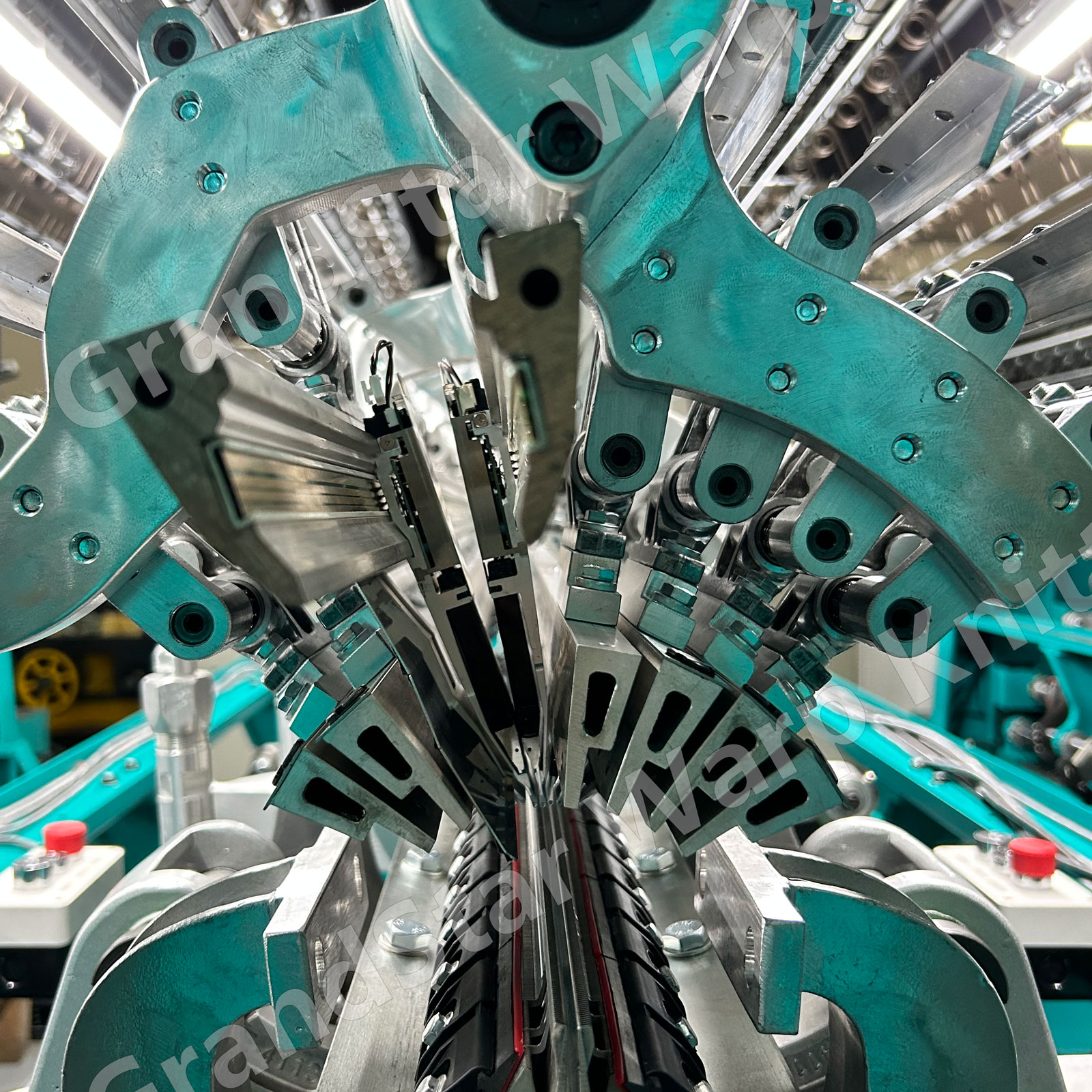

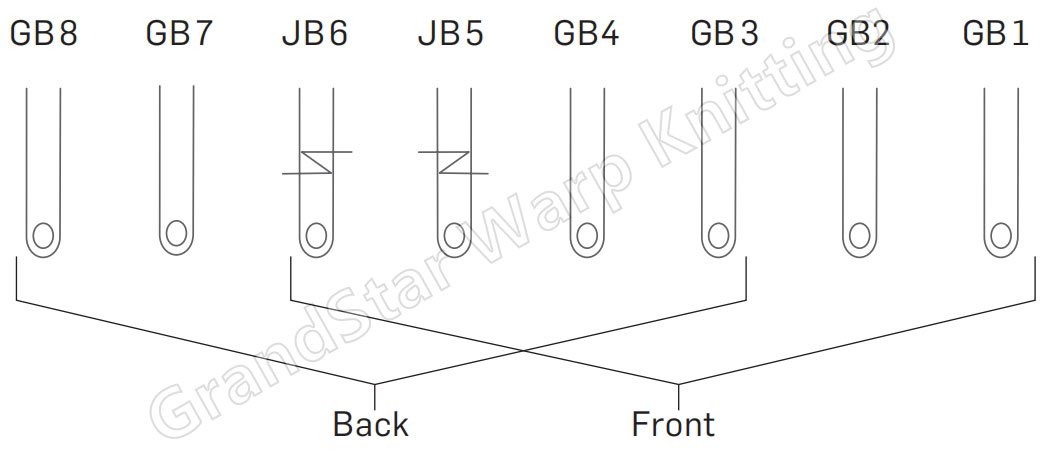

- Bars / Knitting Elements:

- Six ground guide bars

- One Piezo-Jacquard guide bar (split execution)

- GB3, GB4, JB5, and JB6 stitch forming on both needle bars.

- Two individual latch needle bars, two knock-over comb bars, and two stitch comb bars.

- Warp Beam Support: 7 × 812 mm (32″) free-standing.

- GrandStar® (GrandStar COMMAND SYSTEM): Operator interface for configuring, controlling, and adjusting the machine’s electronic functions.

- Yarn Let-off Device: One electronically controlled yarn let-off drive per mounted warp beam position.

- Fabric Take-up: Electronically regulated, driven by a geared motor with four rollers.

- Batching Device: Separate rolling device.

- Pattern Drive: Electronic guide bar drive EL, with all guide bars shogging up to 150 mm.

- Electrical Equipment: Speed-regulated drive with a total connected load of 7.5 KW.

- Voltage: 380V±10% three-phase power supply. Main power cord requirement: at least 4mm² three-phase four-core cable, ground wire at least 6mm².

- Oil Supply: Heating and cooling via circulating air heat exchanger with a filter and dirt-monitoring system.

- Working Conditions:

- Temperature: 25°C ± 3°C

- Humidity: 65% ± 10%

- Floor Pressure: 2000–4000 KG/㎡

Training & Service

Installation & Training

Local Service

LEARN MORE

Application

- Textile Manufacturing: Ideal for producing high-quality, intricate fabrics used in fashion, upholstery, and technical textiles.

- Jacquard Fabric Production: Suitable for complex, multi-patterned fabrics for apparel and home textiles.

- Industrial Fabrics: Useful in creating durable textiles for automotive and industrial applications.

- Home Textiles: Common in producing decorative fabrics for curtains, upholstery, and bedding with intricate jacquard patterns.

- Fashion and Apparel: Perfect for creating premium garments with sophisticated designs and patterns.

- Technical Textiles: Applied in the creation of fabrics used for filtration, protective clothing, and other specialized products.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |