Double-Jacquard Raschel RJPC 4/2F

| Double Jacquard Raschel machine RJPC 4/2F with fallplate for curtains / outerwear – Warp Knitting Machine | |

| Model No. | RJPC 4/2 F (EL) |

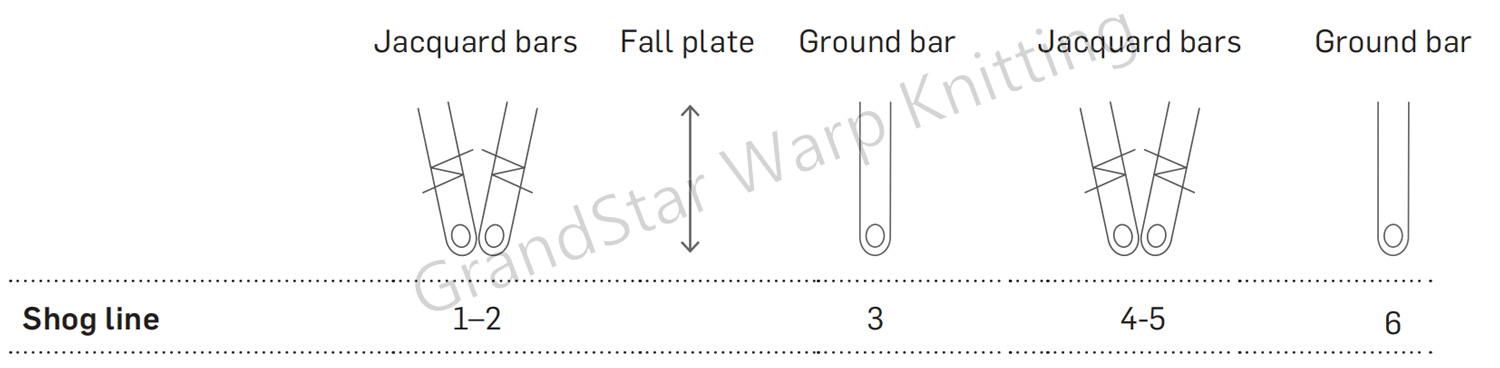

| Ground Bars | 4 Bars |

| Jacquard Bars | 2 Groups (4 Bars) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

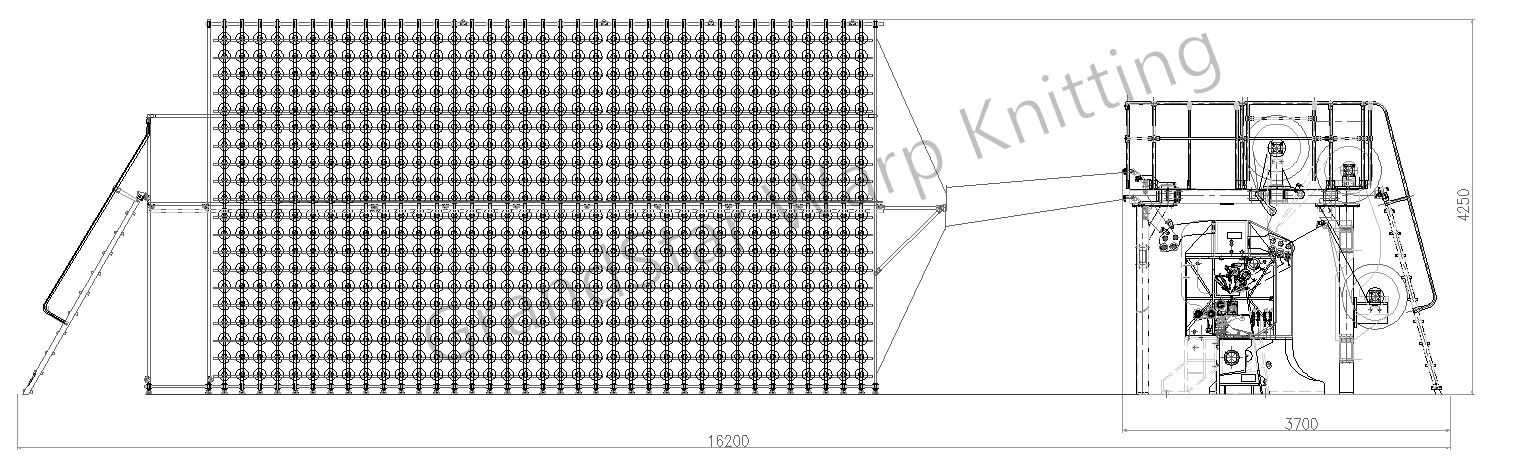

- TECHNICAL DRAWINGS

Working Width / Gauge:

With wheel dimensions of 4318 mm (170 inches), they come in E18 and E24 gauges.

Yarn Let-Off Device:

Three electric control equipments for ground guide bars that has the functionality of multiple speeds is seen.

Pattern Device EL:

Electronically controlled for all ground and Jacquard guide bars for the right patterning.

GrandStar® Command System:

Simplified operator interface for the convenient determination of the particular electronic machine features.

Fabric Take-Up:

Automated and furnished with four rollers with black rubberized surface and perforated with a gear-motor.

Batching Device:

Isolate, rolling unit with a maximum diameter of 685mm (27 inch).

Electrical Equipment:

Speed-controlled motor type with output of 7.5 KW total power and 380V ±10% three-phase power input.

Working Conditions:

Temperature: Temperature: 25±3℃, Humidity: 65±10%, Flooring Pressure: 2-4 kg/CM².

Creel:

Provision of yarn supply from a creel developed and designed to meet needs of the Jacquard machines.

Training & Service

Installation & Training

Technical support is a cornerstone of our warp knitting machine services. To ensure our customers maximize the performance of their machines, we provide comprehensive training programs in multiple formats. These include detailed professional manuals, online guidance, instructional video libraries, and on-site training sessions tailored to specific customer needs.

To date, we have conducted on-site training in over 20 countries and established dedicated local service teams in Turkey, India, Vietnam, Indonesia, and the USA. Our prompt and professional technical support has earned widespread acclaim, reinforcing our reputation for excellence in the global market.

Local Service

Our commitment to exceptional after-sales service extends to Turkey, India, Vietnam, Indonesia, and the USA, with plans to expand our local service teams to additional countries in the near future.

In regions without local service teams, we offer real-time online support as the first line of assistance. Should further intervention be required, we dispatch engineers from the nearest service hub directly to the customer’s facility to provide hands-on support.

Furthermore, we implement a proactive customer care program. Our engineers conduct regular visits—every 1-2 months—to inspect machine performance, advise on maintenance, and ensure the continued stability and efficiency of our machines. This proactive approach enables our customers to maintain optimal operational performance, safeguarding their investment.

Application

- Warp Knitting: Offers a range of fabrics used in fashion & sportswear industries as well as industrial applications.

- Technical Textiles: Appropriate for products such as mesh, net and filter.

- Home Textiles: When used, it is made into upholstery, curtains, and bedding.

- Industrial Fabrics: Effectively suited for automotive, medical, and protective fabric use.

- Jacquard Patterns: A good choice when creating detailed shapes and patterns especially when using materials with complex surface structures in mass productions

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |