Biaxial Warp Knitting Machine

| Chopped Biaxial Warp Knitting Machine For | |

| Model No. | GS-YRS3-MFI |

| Bars Number | 2 Bars |

| Beam Size | 30inch EBC |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

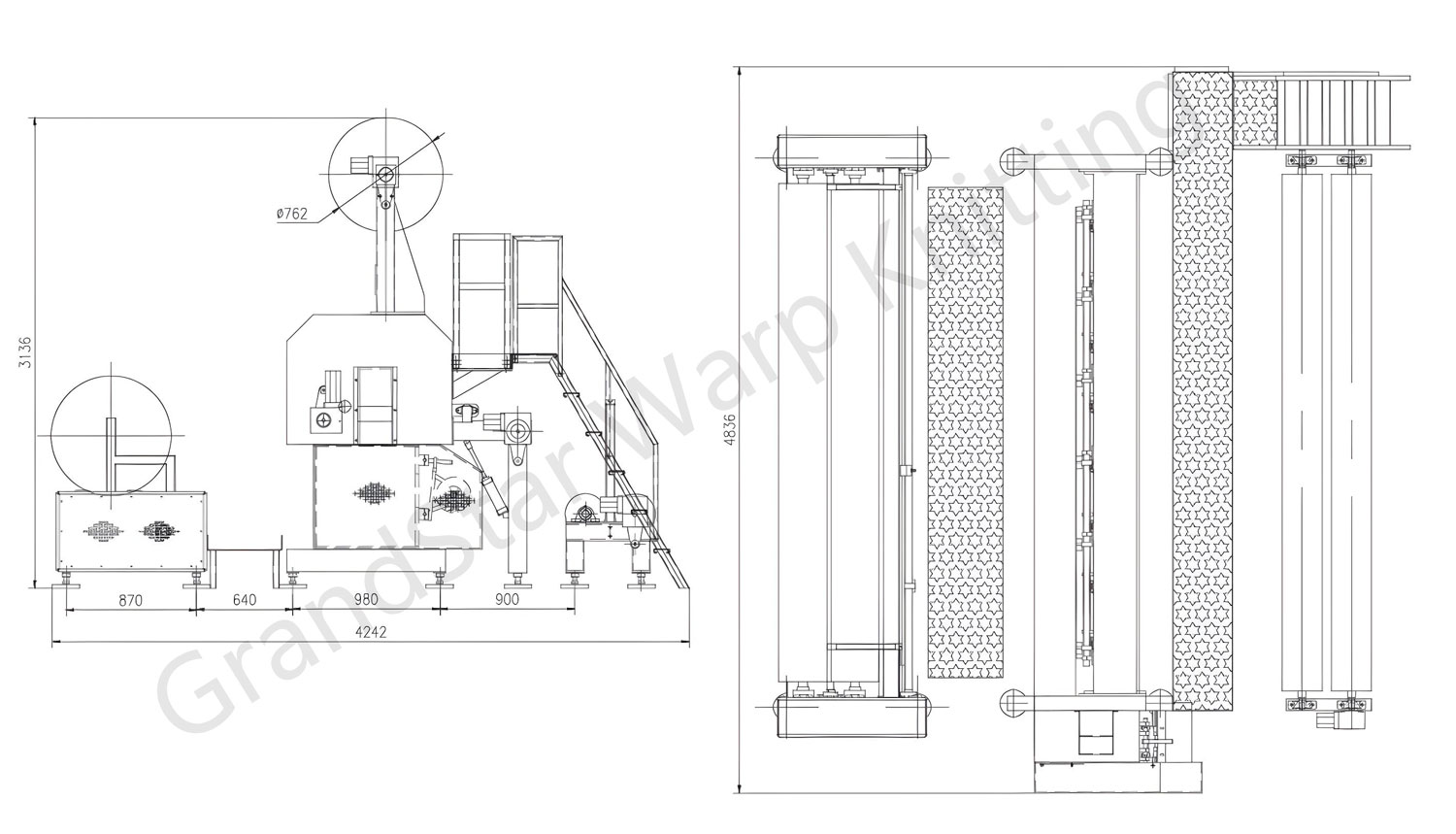

- TECHNICAL DATA

- TECHNICAL DRAWINGS

Chopped Biaxial Warp Knitting Machine

This warp knitting machine is mainly used for making composite textile for wind prower project,cabin cover and aerospace.

Working Width:

- 2565mm = 101″

- 4496mm = 177″

Gauge:

- E7

Bars/Knitting Elements:

- Compound needle bar

- Closing wire bar

- Knock over sinker bar

- Supporting bar

- Counter retaining bar

- 2 ground guide bars

Pattern Drive-N:

N-drive with pattern disc, integrated tempi change gear drive, 1 pattern disk.

Warp Beam Support:

2 warp beam positions for sectional use with a max flange diameter of 30.

Yarn Let-Off Device:

Electronically controlled yarn let-off drive for each mounted warp beam position, driven by geared motor and frequency converter.

Yarn Stop Motion:

Electronically controlled (optional).

Fabric Take-Up:

Electronically controlled fabric take-up, driven by a geared motor and frequency converter.

Batching Device (Standing Separately):

With friction drive by pressure roller, max batch diameter of 914mm (36 inches), driven by geared motor with integrated frequency converter, and controlled to match the stitch courses.

Chopper Device:

1 Chopper Device,Servo System Controlling.

Weft-insertion System:

Weft Insertion,Servo System Controlling.

Motion Control:

Machine control computer manages the basic functions such as main drive, yarn feeding, and fabric take-up.

Operator Interface:

Touch screen in the switch cabinet displays production data.

Electrical Equipment:

- Speed-regulated drive, power-failure safe, including inching motion function.

- Single speed control for the basic functions with a frequency converter.

- Main motor power:

- 2000mm-4400mm width: 13 KW

- 4400mm-6000mm width: 18 KW

Oil Supply:

Immersion lubrication in the crankcase with filter.

Operating Conditions:

Ambient temperature: 25°C (+/-2°C) at 65% relative humidity. Drafts must be avoided, and the machine should be protected against dust and fiber fly. Floor load: 2000-4500 kg/m² depending on the machine type and length. Operational vibrations must be considered during installation.

Training & Service

Installation & Training

Technical support is a cornerstone of our warp knitting machine services. To ensure our customers maximize the performance of their machines, we provide comprehensive training programs in multiple formats. These include detailed professional manuals, online guidance, instructional video libraries, and on-site training sessions tailored to specific customer needs.

To date, we have conducted on-site training in over 20 countries and established dedicated local service teams in Turkey, India, Vietnam, Indonesia, and the USA. Our prompt and professional technical support has earned widespread acclaim, reinforcing our reputation for excellence in the global market.

Local Service

Our commitment to exceptional after-sales service extends to Turkey, India, Vietnam, Indonesia, and the USA, with plans to expand our local service teams to additional countries in the near future.

In regions without local service teams, we offer real-time online support as the first line of assistance. Should further intervention be required, we dispatch engineers from the nearest service hub directly to the customer’s facility to provide hands-on support.

Furthermore, we implement a proactive customer care program. Our engineers conduct regular visits—every 1-2 months—to inspect machine performance, advise on maintenance, and ensure the continued stability and efficiency of our machines. This proactive approach enables our customers to maintain optimal operational performance, safeguarding their investment.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |