Laser Stop Device for Warp Knitting

| Laser Stop Device for Warp Knitting Machine | |

| Model No. | 1/2/3/4/5/6/7/8/9 Bars |

| Application | For Yarn Breaking Detection |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Revolutionizing Warp Knitting Efficiency: The Advanced Laser Stop Device

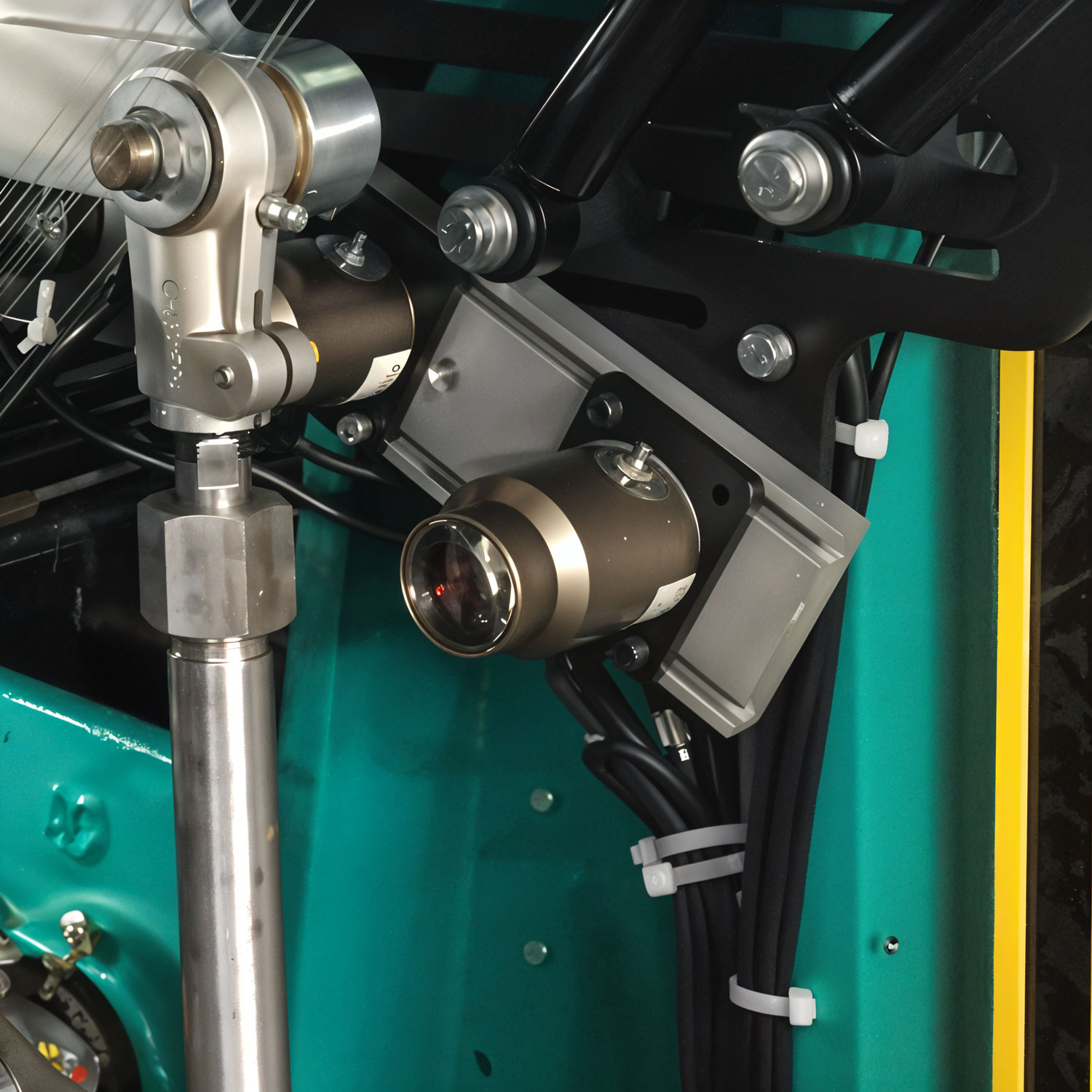

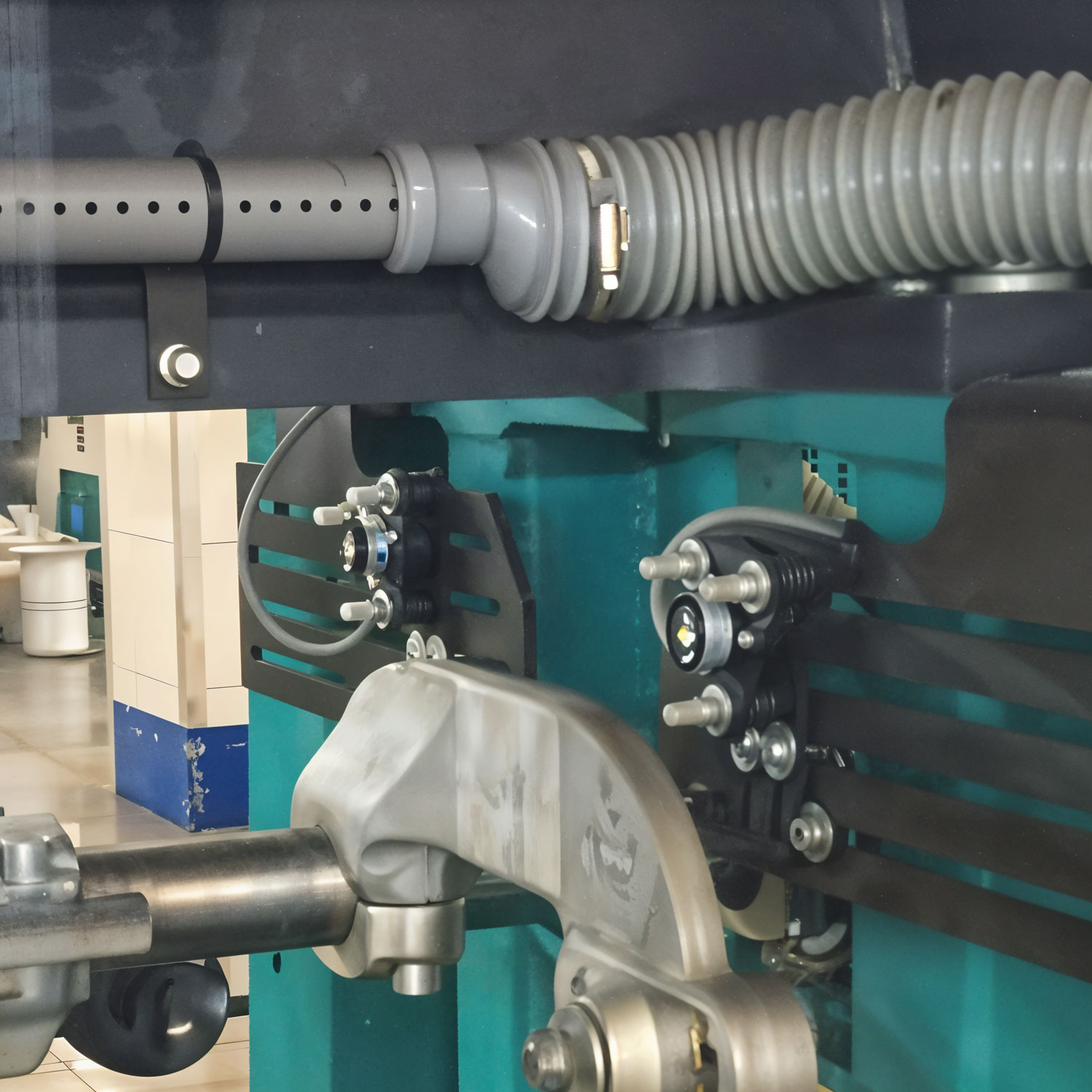

In the fast-evolving world of warp knitting, efficiency and precision are paramount. Our Laser Stop Device is an advanced, one-to-eight-head laser-controlled yarn break detector engineered to outperform traditional mechanical sensors. Designed to meet the growing market demand, this innovative solution significantly enhances operational stability while minimizing labor dependency—making it the ultimate upgrade for warp knitting machines such as TM2, TM3, HKS3-M, and double Raschel bar machines.

Unmatched Advantages Over Conventional Yarn Break Detection

Unlike conventional yarn break detection systems that rely on mechanical contact, our laser stop device provides a contact-free, high-precision monitoring solution. This revolutionary technology offers multiple advantages:

- Superior Accuracy: Detects yarn breaks instantly with laser precision, eliminating false detections caused by mechanical wear.

- Reduced Machine Downtime: Ensures seamless operation by preventing unnoticed yarn breaks, enhancing production efficiency.

- Universal Compatibility: Works flawlessly with Karl Mayer, LIBA, and all Chinese brand warp knitting machines.

- Labor Cost Reduction: Automates yarn break detection, minimizing the need for manual monitoring and intervention.

- Easy Installation & Operation: Simple plug-and-play setup tailored to customer-specific requirements with flexible control configurations.

Optimized for a Wide Range of Warp Knitting Machines

Our yarn break laser stop device is a must-have component for a variety of warp knitting machines, including:

- Tricot warp knitting machines

- Terry towel warp knitting machines

- Double needle bar warp knitting machines

- Warping machines

Whether you are running high-speed tricot machines or complex double Raschel bar machines, our laser stop system ensures unparalleled reliability, precision, and adaptability.

Customizable Solutions for Your Specific Production Needs

Understanding that every knitting facility has unique requirements, we offer tailor-made laser stop solutions. Each system includes:

- A central control box for seamless integration into existing machine configurations.

- Customizable laser detection heads that adapt to different machine types and production scales.

With our customizable configurations, you can optimize your warp knitting operations, achieving higher efficiency and reducing production costs.

Application

Why Choose Our Laser Stop Device?

As a leading warp knitting machine manufacturer, we are committed to delivering high-performance solutions that drive efficiency, reliability, and profitability. Our laser stop device is designed to enhance your production line with:

- Cutting-edge laser detection technology that surpasses traditional mechanical systems.

- Durability and long service life with minimal maintenance requirements.

- Broad compatibility with top industry brands and models.

- Proven performance in global warp knitting applications.

Enhance Your Warp Knitting Efficiency Today

Upgrade your warp knitting machinery with our state-of-the-art laser stop device. Contact us today to learn more about how our innovative solutions can redefine your production efficiency while reducing labor costs.

Precision and Efficiency: The Ultimate Solution for Warp Knitting Quality Control

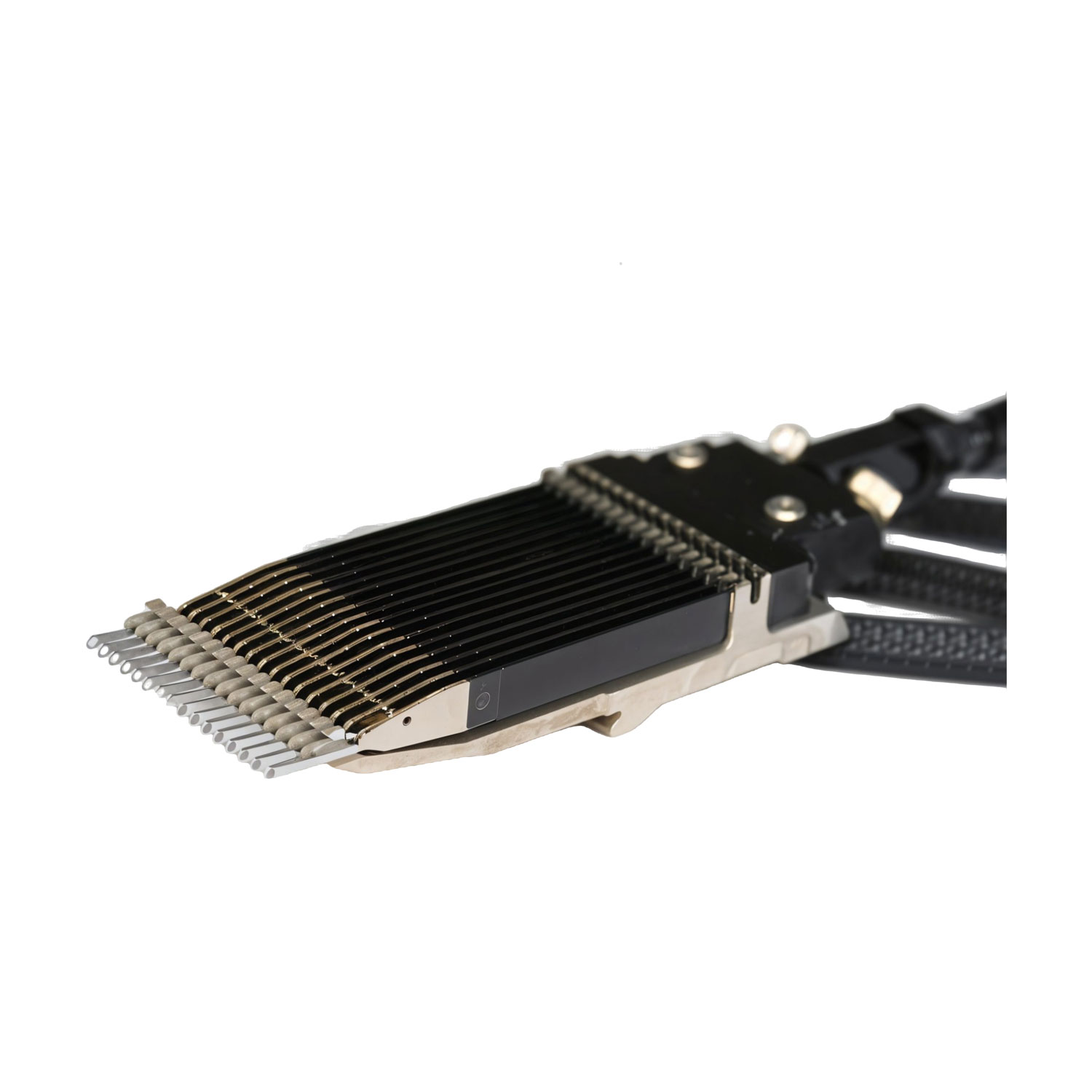

In the highly competitive warp knitting industry, precision and efficiency in quality control are crucial for maintaining superior product standards. Our advanced Warp Knitting Laser Inspection System sets itself apart from competitors with cutting-edge technology, exceptional sensitivity, and user-friendly operation.

🔹 Superior Voltage Stability for Uninterrupted Operation

Unlike conventional inspection systems that suffer from voltage fluctuations, our system operates seamlessly on a single-phase 220V working and activating voltage. This ensures stable performance and eliminates the risk of disruptions, giving manufacturers peace of mind during production.

🔹 Industry-Leading Working Width Adaptability

From compact operations to large-scale production lines, our system accommodates a remarkable working width of 60-400 inches. This far exceeds the limitations of standard inspection devices, making it the perfect choice for both small and oversized warp knitting fabrics.

🔹 Unmatched Sensitivity with 15D Detectable Titer

Detecting fine filament deviations is critical in high-precision textiles. Our system is engineered to identify filament irregularities as fine as 15D (denier), a level of accuracy that outperforms conventional inspection equipment. This ensures flawless quality control for the most demanding textile applications.

🔹 Customizable Laser Inspection with Up to 12 Components

Equipped with 1 to 12 laser components, our system offers unparalleled customization. Manufacturers can configure the inspection system based on their specific fabric types and defect detection requirements, achieving optimized performance for various textile applications.

🔹 Intelligent Sensitivity Adjustment via Intuitive Panel Control

Unlike traditional models with complex manual calibrations, our system features an intuitive panel-based sensitivity adjustment. This enables rapid, precise tuning, reducing downtime and enhancing production efficiency.

🔹 Reliable Relay Contact Output for Seamless Integration

Designed for hassle-free connectivity, our inspection system provides a relay contact output, ensuring smooth integration into existing production lines without requiring additional complex modifications.

🔹 Powerful Optional Fan System for Enhanced Performance

For operations requiring advanced airflow management, we offer an optional 750W fan power feature. This ensures stable operation in high-speed knitting environments, enhancing the durability and efficiency of the inspection system.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |