Waste Yarn Winding Machine

| Waste Yarn Winding Machine for Warp Knitting Machine | |

| Model No. | 1200 RPM |

| Application | For Waste Yarn Collection |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

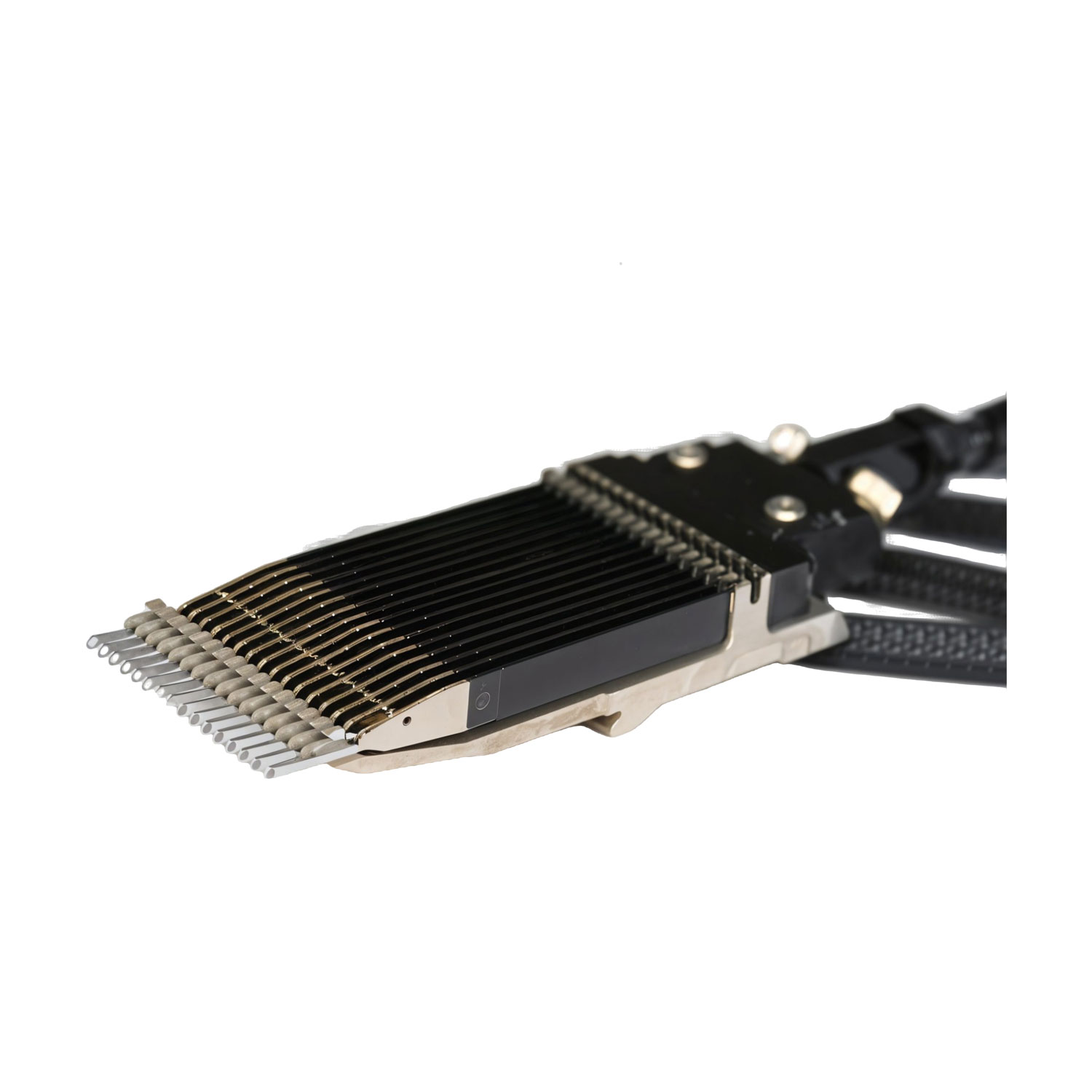

Superior Waste Yarn Winding Machine for Warp Knitting

In the fast-paced textile industry, efficiency, precision, and waste reduction are critical. Our waste yarn winding machine stands out as the ultimate solution for optimizing selvage yarn management in warp knitting. This machine offers unmatched advantages over conventional winding equipment.

🔹 Unparalleled Precision & Consistency

Unlike standard selvage yarn winders, our machine is engineered for exceptional winding precision. The advanced tension control system maintains uniform yarn tension throughout the process, eliminating inconsistencies that can compromise fabric quality. This feature significantly reduces material waste, making it the ideal choice for high-end textile manufacturers.

🔹 Optimized for Diverse Yarn Types

With adjustable speed and tension settings, our waste yarn winder accommodates a wide range of yarn types and thicknesses, from fine deniers to heavy-duty industrial threads. This adaptability ensures seamless integration into various warp knitting applications, providing unmatched flexibility for manufacturers.

🔹 Enhanced Automation for Maximum Efficiency

Equipped with an intelligent electronic monitoring system, the machine automatically detects and corrects irregularities, preventing yarn breakage and tangling. Features such as automatic stop mechanisms and real-time error detection further enhance operational efficiency, reducing downtime and labor costs.

🔹 Durability & Low Maintenance

Built with high-quality components, our selvage yarn winding machine offers exceptional durability and long-term reliability. The low-maintenance design minimizes the need for frequent servicing, ensuring uninterrupted production cycles and cost-effectiveness.

🔹 Eco-Friendly & Cost-Saving Solution

By optimizing waste yarn utilization, this machine contributes to a more sustainable manufacturing process. The efficient winding mechanism ensures that excess yarn is effectively recycled, reducing raw material wastage and operational expenses.

Application

💡 Why Choose Our Waste Yarn Winding Machine?

- Higher Productivity: Streamlined operations lead to increased output and reduced manual intervention.

- Superior Winding Quality: Advanced technology ensures flawless yarn winding for premium fabric production.

- Adaptability: Versatile settings allow processing of various yarn specifications.

- Smart Automation: Reduces operator workload while maximizing efficiency.

- Cost-Effective: Lower energy consumption and minimal waste reduce production costs.

📢 Elevate Your Warp Knitting Efficiency Today

Stay ahead in the textile industry with our high-performance waste yarn winding machine. Experience unparalleled precision, efficiency, and cost savings with cutting-edge automation and superior build quality. Contact us now to learn how our solution can enhance your production capabilities!

Product Specifications

| Specification | Details |

|---|---|

| Yarn Dtex | 15dtex-2000dtex |

| Diameter | Outer diameter = 200mm, Inner diameter = 105mm |

| Winding Speed | 0~1200 RPM/MIN |

| Yarn Tension | 0~100CN |

| Tension Roller Route | 120mm |

| Ceramic Eyelet | Ceramic components made of alumina |

| Power Supply | AC 100V-240V |

| Power | 20W |

| Plug | EUROPEAN/BRITISH |

| Size | 280x200x210 |

| Weight | 7kg |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |