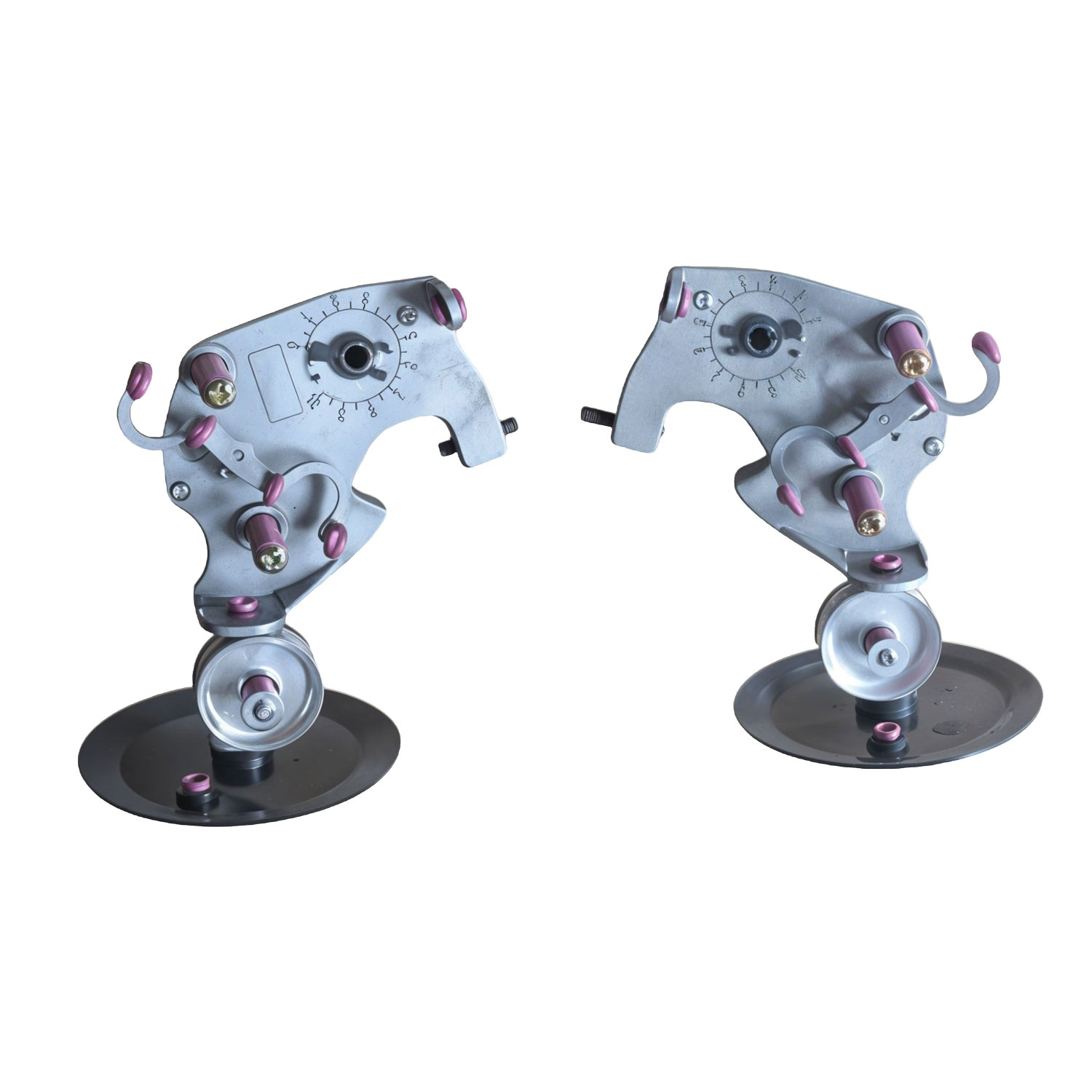

KFD Yarn Tensioner

| KFD Yarn Tensioner / Warp Knitting Machine Creel Parts | |

| Model No. | KFD |

| Application | For Waste Yarn Collection |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

KFD Yarn Tensioner – Unrivaled Precision for Warp Knitting Excellence

In modern warp knitting, precision tension control is the key to achieving high-quality fabrics. The KFD Yarn Tensioner stands out as an industry-leading solution, delivering unparalleled stability and efficiency that outperforms conventional tension devices. Engineered to regulate warp yarn tension with absolute accuracy, our advanced tensioner minimizes defects, enhances fabric uniformity, and optimizes machine performance.

🔹 Superior to Conventional Tension Devices

Unlike traditional mechanical tension systems that suffer from fluctuations and wear over time, the KFD Yarn Tensioner integrates a cutting-edge hydraulic control mechanism. This ensures consistent yarn tension across all knitting operations, eliminating irregularities and significantly improving fabric quality.

🔹 How the KFD Yarn Tensioner Revolutionizes Warp Knitting

At the core of our innovation is a hydraulic oil-based tension regulation system. This system continuously monitors and adjusts yarn tension in real time, providing unmatched stability throughout the knitting process. By leveraging advanced sensor technology, the KFD Yarn Tensioner guarantees:

- Precise and automated tension adjustments, reducing manual intervention.

- Minimized yarn breakage, enhancing operational efficiency.

- Optimized yarn feed for seamless fabric formation.

🔹 Key Advantages Over Competing Systems

Choosing the KFD Yarn Tensioner translates to significant benefits in warp knitting production:

✅ Enhanced Fabric Quality

Maintains consistent yarn tension, resulting in flawless, high-density warp-knitted fabrics with superior texture and strength.

✅ Increased Productivity

Reduces machine downtime by preventing yarn breakages, allowing for smoother, uninterrupted knitting operations.

✅ Cost Efficiency

Minimizes material waste and operational costs by eliminating excessive yarn loss and fabric defects.

✅ Versatile Adaptability

Adjustable to accommodate different yarn types and complex knitting patterns, ensuring superior performance across various textile applications.

Application

🔹 Versatile Applications in the Textile Industry

The KFD Yarn Tensioner is an indispensable component in diverse textile manufacturing processes, including:

- Warp Knitting: Guarantees uniform tension for high-performance technical textiles and intricate warp-knitted designs.

- Traditional Weaving: Optimizes yarn control in conventional weaving looms, enhancing durability and texture consistency.

- Circular Knitting: Ensures seamless, high-quality fabric production by regulating yarn tension with precision.

🚀 Elevate Your Warp Knitting Performance with KFD Yarn Tensioner

By integrating the KFD Yarn Tensioner into your textile production line, you gain a competitive edge with superior fabric quality, increased efficiency, and cost savings. Experience the next generation of warp knitting tension control—where precision meets performance.

KFD Tensioner for Different Materials

Explore our range of advanced tension sensors designed for various yarn types. Each sensor ensures precision and efficiency in warp knitting processes.

| Model | Material | Image | Range (cN) |

|---|---|---|---|

KFD-B |

Filament yarn | KFD-B Sensor | 2~20 cN / 3~24 cN |

KFD-2 |

Filament yarn | KFD-2 | 2~12 cN |

KFD-SP |

Spun yarn | KFD-SP | 6~60 cN |

KFD-Air |

Filament yarn, Technical yarn | KFD-Air | 10~100 cN / 30~230 cN |

OPTO-STOP |

Spun yarn | OPTO-STOP | – |

Disc Tense |

Spun yarn | Disc Tense | 5~70 cN |

Accutense 0° |

Glass | Accutense 0° | 2~35 cN |

Accutense 30° |

Glass, Technical yarn | Accutense 30° | 5~35 cN / 5~60 cN / 10~120 cN / 30~250 cN |

Accutense 90° |

Glass, Technical yarn | Accutense 90° | 5~35 cN / 5~60 cN / 10~120 cN / 30~250 cN |

ISOTENSE |

Filament yarn, Spun yarn | ISOTENSE | 0~30 cN / 0~70 cN / 6~160 cN |

Multitense |

Filament yarn, Glass, Technical yarn, Spun yarn | Multitense | 3~150 cN |

Megatense |

Filament yarn, Glass, Technical yarn | Megatense | 4~70 cN / 6~250 cN / 6~500 cN |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |