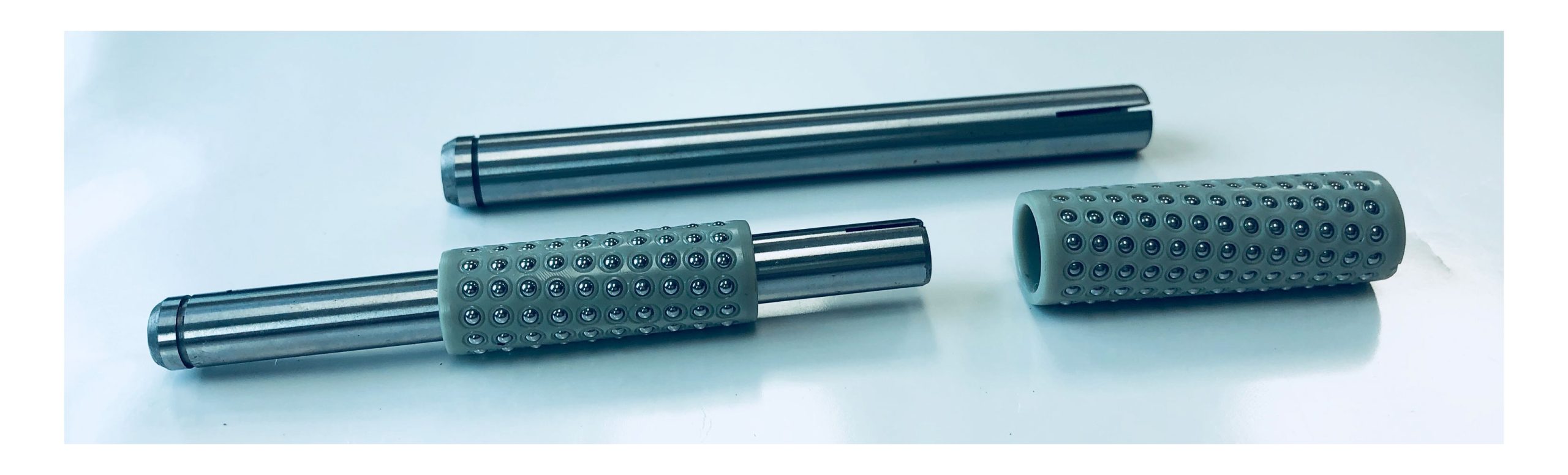

Ball Cage

| Ball Cage For Warp Knitting Machine | |

| Model No. | Ball Cage |

| Application | For Bar’s Movement |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Warp Knitting Machine Ball Cage: Enhancing Precision, Productivity, and Fabric Quality

Superior Performance in Warp Knitting Machines

In the highly competitive textile manufacturing industry, precision and efficiency are key to producing high-quality fabrics. The warp knitting machine ball cage plays a crucial role in optimizing machine performance, ensuring smoother operation, increased productivity, and superior fabric quality.

What Is a Warp Knitting Machine Ball Cage?

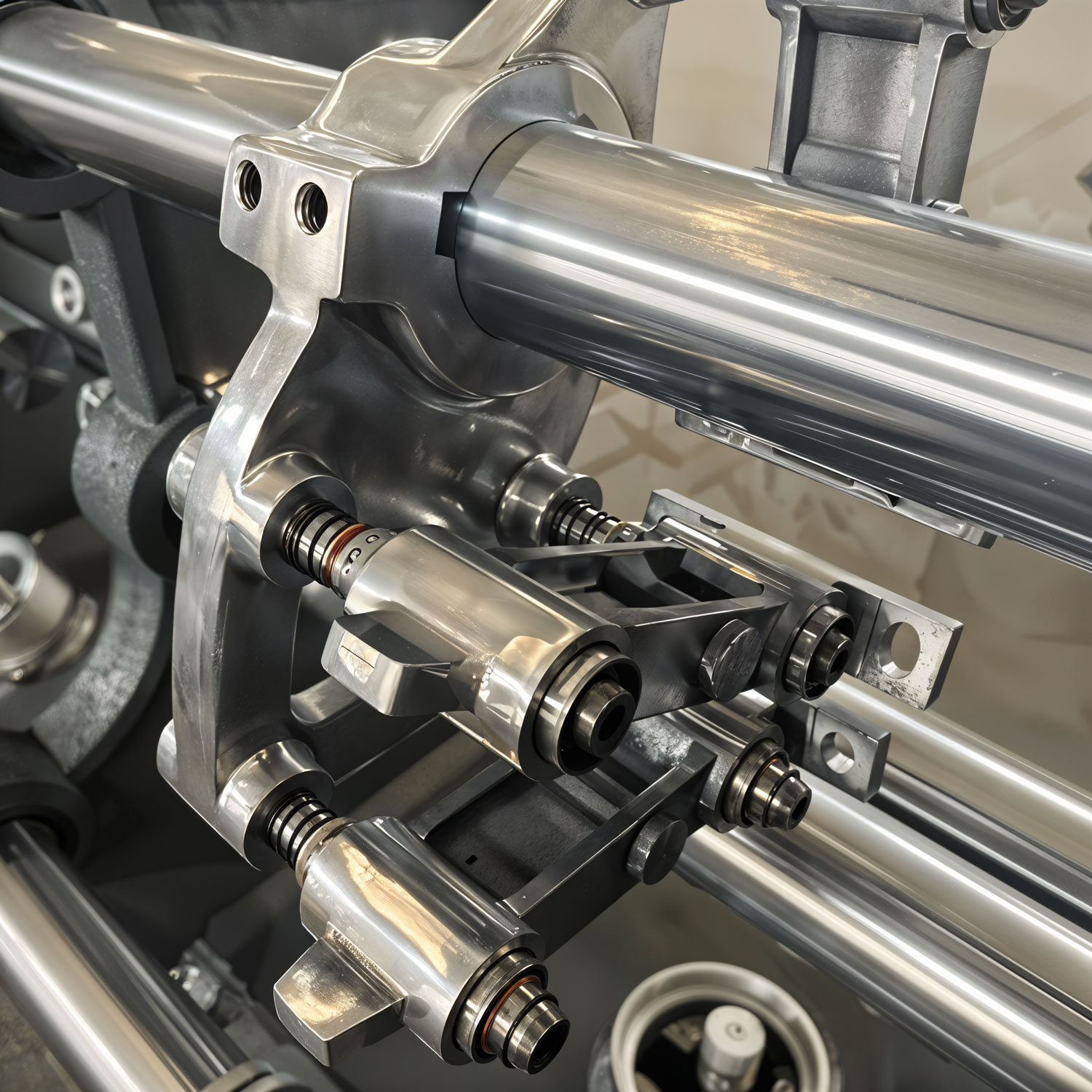

The warp knitting machine ball cage is a meticulously engineered component that provides stable and precise movement of the needle bar. Comprising high-precision ball bearings enclosed within a structured cage, it facilitates seamless and frictionless operation, eliminating challenges such as misalignment and uneven fabric tension.

How Does the Ball Cage Work?

Operating on the principle of minimizing friction while maximizing precision, the ball cage ensures:

- Ultra-smooth needle bar movement

- Reduced lateral deflection

- Perfect alignment for consistent loop formation

By preventing excessive wear and breakage, it enhances machine longevity and operational efficiency, making it an indispensable component for modern high-speed textile production.

Key Advantages Over Competitors’ Systems

1. Increased Productivity and Operational Efficiency

With a high-performance ball cage system, warp knitting machines can operate at higher speeds without sacrificing accuracy. Benefits include:

- Higher knitting speeds and increased production output

- Lower risk of needle breakage, reducing downtime

- Extended machine lifespan and reduced maintenance costs

2. Superior Fabric Quality With Impeccable Precision

Ensuring precise needle positioning, the ball cage results in:

- Consistent fabric tension and flawless stitch formation

- Minimized defects such as skipped stitches

- High-end textile quality meeting global industry standards

3. Expanded Design Possibilities and Versatility

With enhanced needle guidance, manufacturers can produce:

- Intricate patterns and delicate textures

- Innovative textile solutions for high-end markets

- Differentiated products in a competitive industry

Application

Why Choose Our Warp Knitting Machine Ball Cage?

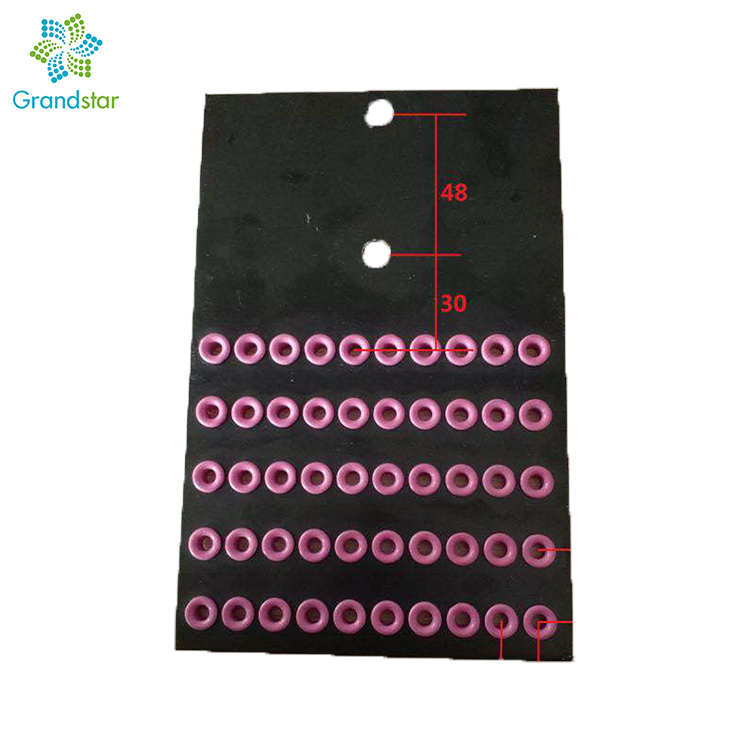

At GrandStar Warp Knitting, we integrate industry-leading ball cage technology to ensure unmatched precision, efficiency, and fabric quality. Our ball cage systems feature:

- Durable materials for extended lifespan

- Advanced engineering to minimize friction

- Precision ball bearings for superior needle guidance

Conclusion

Investing in a high-performance warp knitting machine ball cage ensures a more efficient, reliable, and high-quality textile production process. Upgrade to GrandStar’s precision-engineered warp knitting machines and experience the difference in speed, quality, and innovation.

Order Specification Form

Fill in the required specifications accurately before submission

| No. | Inner Diameter (mm) | Outer Diameter (mm) | Length (mm) |

|---|---|---|---|

| 1 | 24 | 32 | 110 |

| 2 | 24 | 32 | 96 |

| 3 | 23 | 31 | 90 |

| 4 | 18 | 25 | 90 |

| 5 | 24 | 32 | 85 |

| 6 | 12 | 17 | 53 |

| 7 | 12 | 17 | 51 |

| 8 | 12 | 17 | 43 |

| 9 | 10 | 15 | 50 |

| 10 | 10 | 15 | 43 |

For custom sizes or special requirements, please contact our sales team.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |