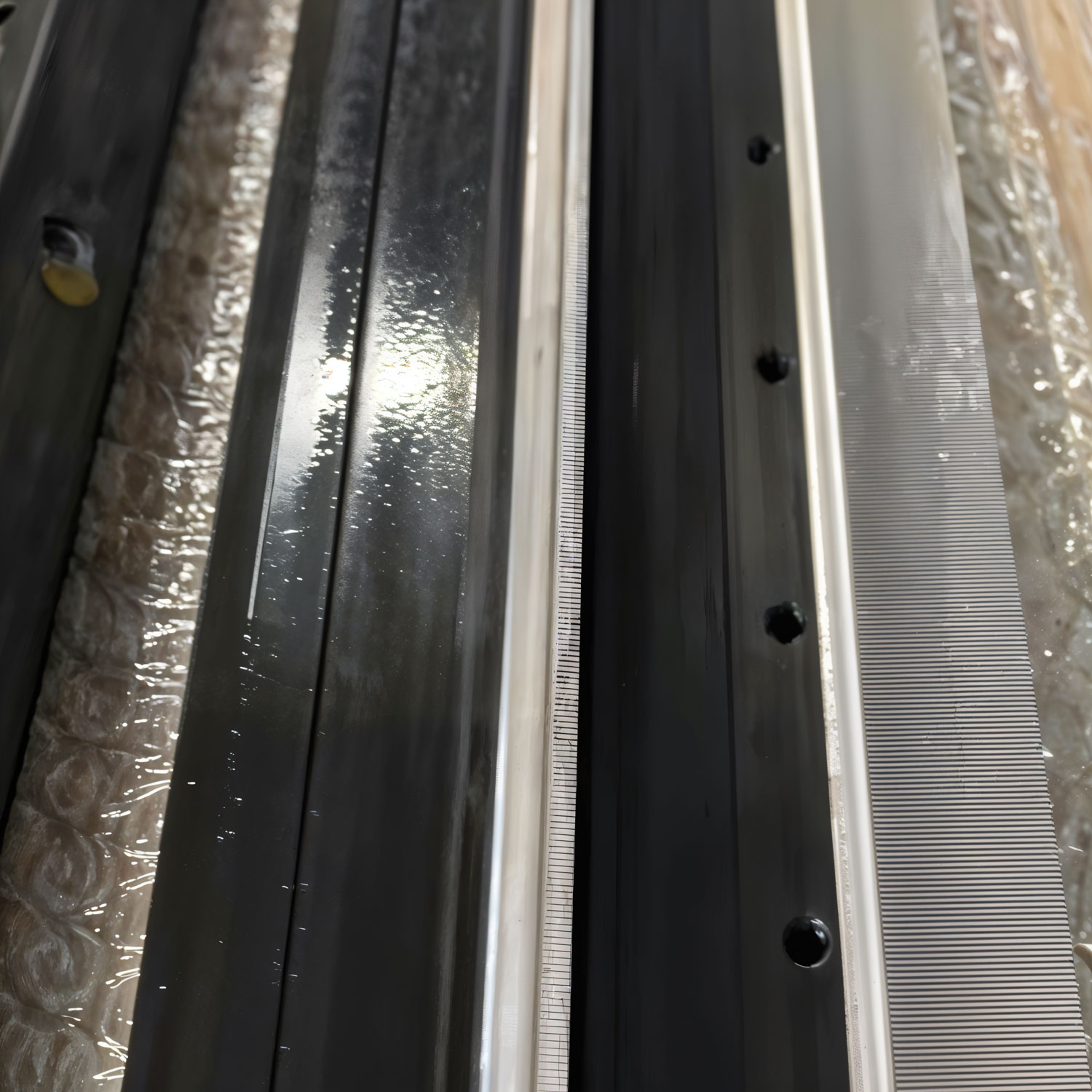

Needle Bar (Carbon-Fiber)

| Needle Bar For Warp Knitting Machine | |

| Model No. | Carbon-Fiber / Aluminum |

| Application | For Bar’s Movement |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

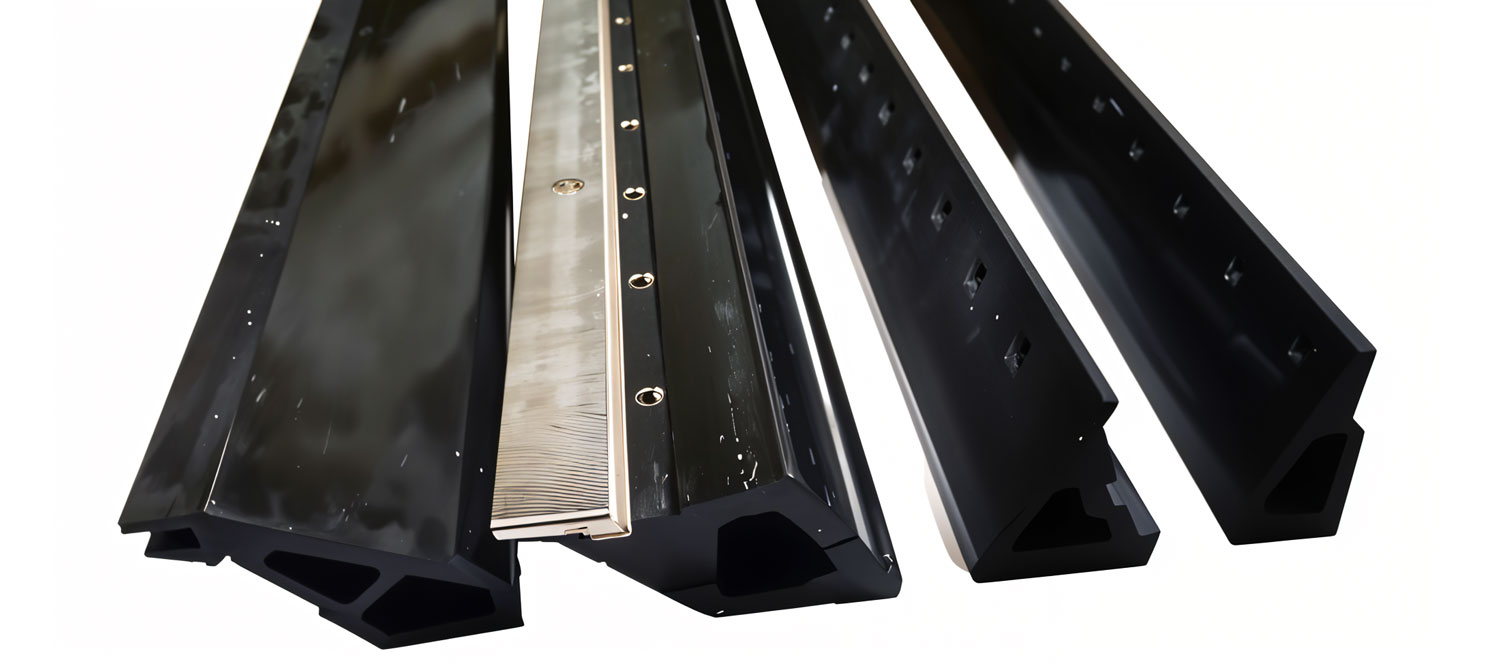

Premium Needle Beds and Needle Bars for Warp Knitting Machines

Precision, Durability, and Innovation

In warp knitting technology, the needle bed is a critical component that directly impacts machine performance, fabric quality, and production efficiency. At GRANDSTAR, we specialize in manufacturing high-precision needle beds and needle bars designed for superior performance across various warp knitting machines, including Karl Mayer, Liba, and Chinese-brand machines.

Unparalleled Material Innovation: Aluminum & Carbon Fiber

Unlike conventional manufacturers who primarily rely on aluminum, we have pioneered the use of high-strength carbon fiber needle beds, significantly enhancing durability, precision, and operational stability. Carbon fiber, compared to traditional aluminum-magnesium alloy, offers:

- Higher rigidity with less deformation over prolonged use

- Lightweight properties that reduce mechanical stress and enhance efficiency

- Greater wear resistance, ensuring a longer lifespan and lower maintenance costs

By integrating years of expertise and adhering to strict quality standards, our needle beds consistently outperform standard alternatives in the market, earning the trust of professional customers worldwide.

Comprehensive Solutions: Needle Beds for All Warp Knitting Machines

We manufacture compound needle beds, sinker needle beds, and tongue needle beds tailored for various machine types, including:

- Tricot warp knitting machines

- Terry towel warp knitting machines

- Double needle bar warp knitting machines

- Raschel warp knitting machines

- Weft insertion machines

Our precision-engineered needle beds ensure exceptional pattern accuracy, minimal vibration, and optimal fabric formation, making them the preferred choice for textile professionals demanding high-performance components.

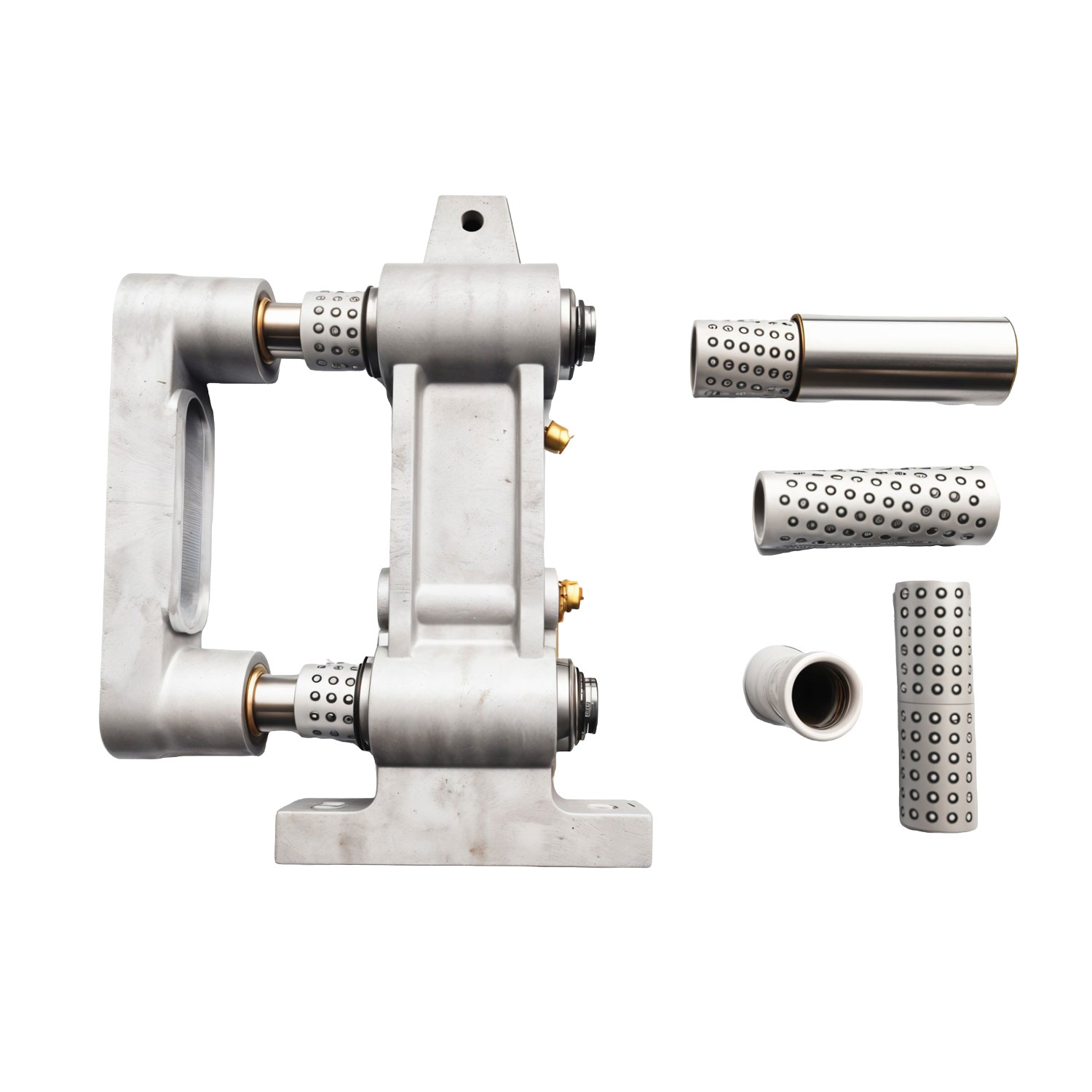

Advanced Needle Bar Technology: Precision for Every Application

Beyond needle beds, we offer a full range of high-precision needle bars, including:

- Compound needle bars

- Latch needle bars

- Guide needle bars

- Sinking needle bars

- Knock-over bars

With state-of-the-art production capabilities, our professional processing equipment can manufacture needle bars up to 400 inches in length, meeting the diverse requirements of both Tricot and Raschel warp knitting machines. The transition from traditional aluminum-magnesium alloy to carbon fiber needle bars further enhances strength, flexibility, and longevity, outperforming conventional alternatives in the industry.

Application

Why Choose Our Needle Beds & Needle Bars?

- ✅ Superior Material Innovation – Carbon fiber technology for higher precision and durability

- ✅ Versatile Compatibility – Designed for Karl Mayer, Liba, and Chinese-brand warp knitting machines

- ✅ High-Precision Manufacturing – Advanced processing for needle bars up to 400 inches

- ✅ Exceptional Quality Assurance – Stringent testing and decades of expertise ensure reliability and consistency

At GRANDSTAR, we don’t just supply components – we deliver performance-driven solutions that empower manufacturers to achieve higher efficiency, lower costs, and superior fabric quality.

📩 Contact us today to learn more about how our premium needle beds and needle bars can enhance your warp knitting operations.