Push Rod

| Push Rod For Warp Knitting Machine | |

| Model No. | Push Rod |

| Application | For Machine Bar’s Movement |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Superior Push Rod Solutions for High-Performance Warp Knitting Machines

Push rods are essential components in warp knitting machines, directly impacting machine stability, precision, and durability. At GrandStar Warp Knitting, we engineer push rods with advanced materials and superior craftsmanship, ensuring optimal performance in high-speed and high-precision knitting applications.

Carbon Fiber Push Rods for Tricot Warp Knitting Machines

Tricot warp knitting machines demand exceptional quality and precision, and our push rods are designed to meet these high standards. Unlike conventional options, our push rods are made from carbon fiber, offering significant advantages over standard metal or composite rods.

- Lightweight & High Strength: Carbon fiber ensures reduced weight while maintaining exceptional rigidity, minimizing vibration and enhancing knitting accuracy.

- Durability & Extended Lifespan: Our push rods are designed for long-term use, resisting wear and deformation even under continuous high-speed operation.

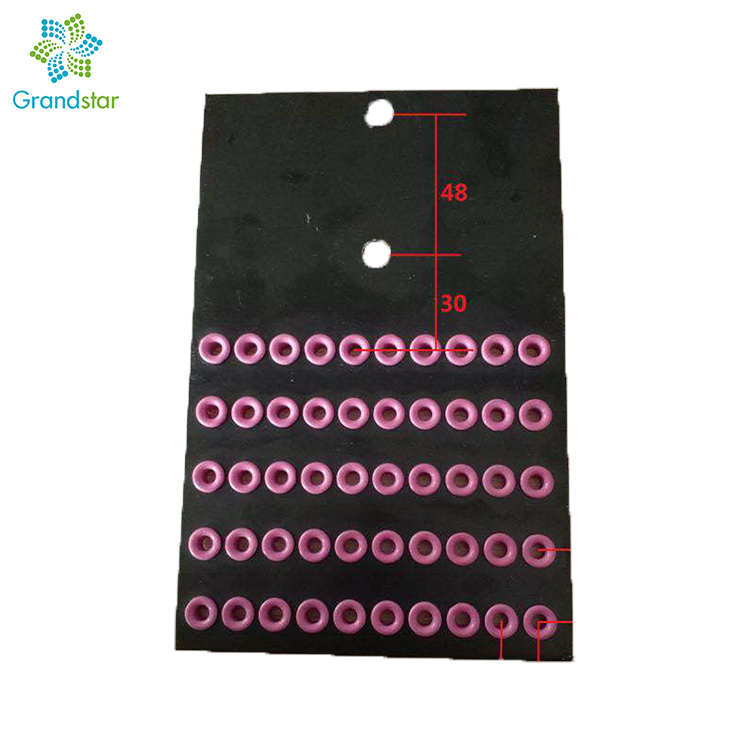

- Precision Engineering: Available in two diameters (D20 and D25) to match diverse machine requirements, with D18 rod heads made from imported high-performance material for superior wear resistance and extended service life.

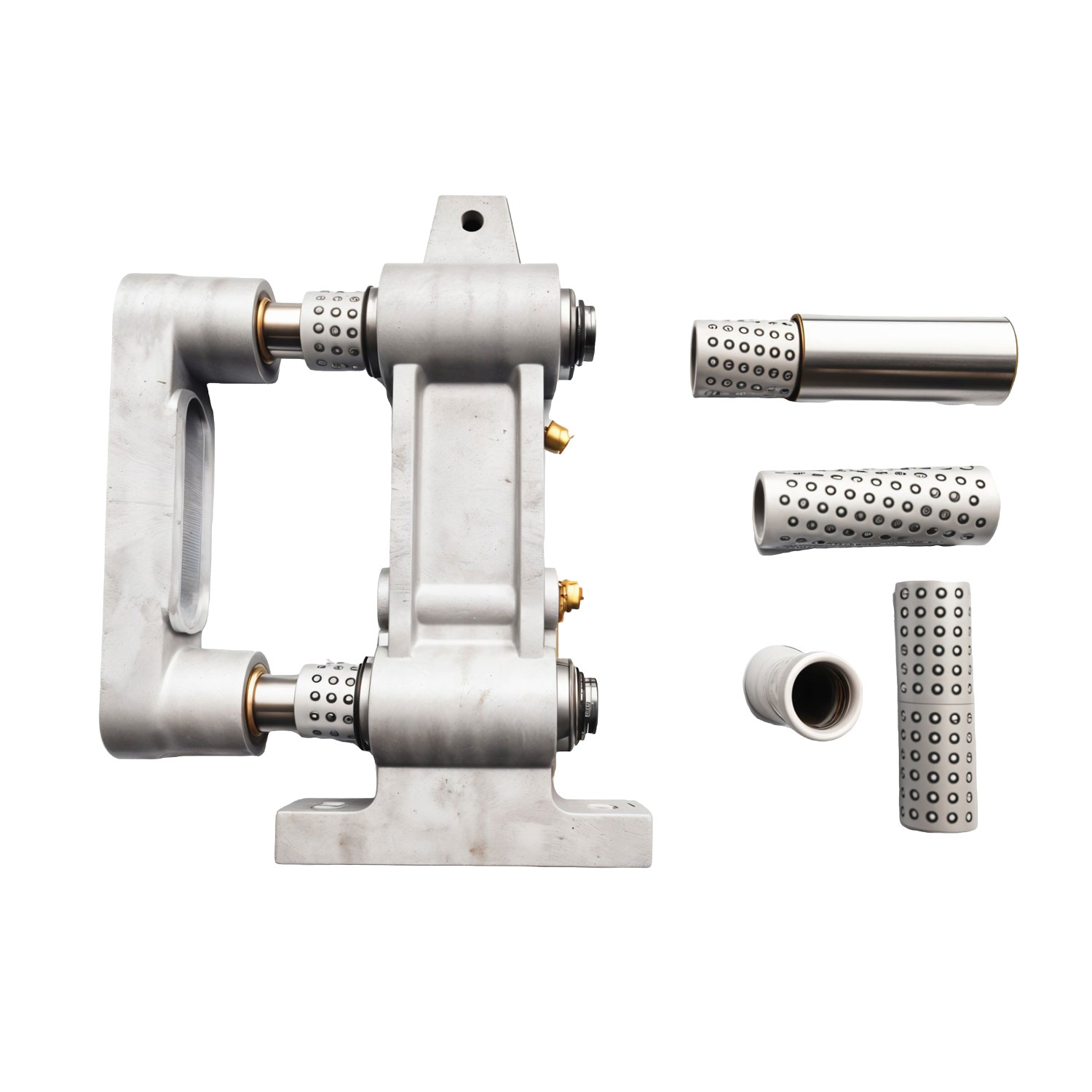

High-Quality Push Rods for Double Needle Bar Warp Knitting Machines

The quality of push rods in double needle bar warp knitting machines varies significantly in the market. While some manufacturers opt for cheaper plastic head push rods, these compromise durability and operational stability.

At GrandStar Warp Knitting, we provide premium push rods specifically designed for RD-type warp knitting machines, offering the following advantages:

- Rustproof & Reinforced Design: Our push rods feature an electroplated exterior, providing superior corrosion resistance and enhanced structural strength compared to conventional options.

- High-End Imported Rod Head Material: Unlike plastic alternatives, our push rod heads use premium materials, ensuring greater durability, improved wear resistance, and a longer operational lifespan.

- Optimized Performance for RD Machines: Designed for high-efficiency double needle bar knitting, our push rods enhance machine performance, reducing maintenance frequency and ensuring consistent, high-quality fabric production.

Why Choose GrandStar Warp Knitting Push Rods?

- ✅ Industry-Leading Materials – Carbon fiber and electroplated finishes outperform traditional push rod materials.

- ✅ Extended Service Life – Imported rod heads and premium construction minimize wear, reducing replacement costs.

- ✅ Proven Stability & Performance – Trusted by professional manufacturers worldwide for precise, high-speed knitting operations.

By choosing GrandStar Warp Knitting push rods, you ensure maximum efficiency, superior durability, and an optimized knitting process—setting your production apart from the competition.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |