Reed Needle

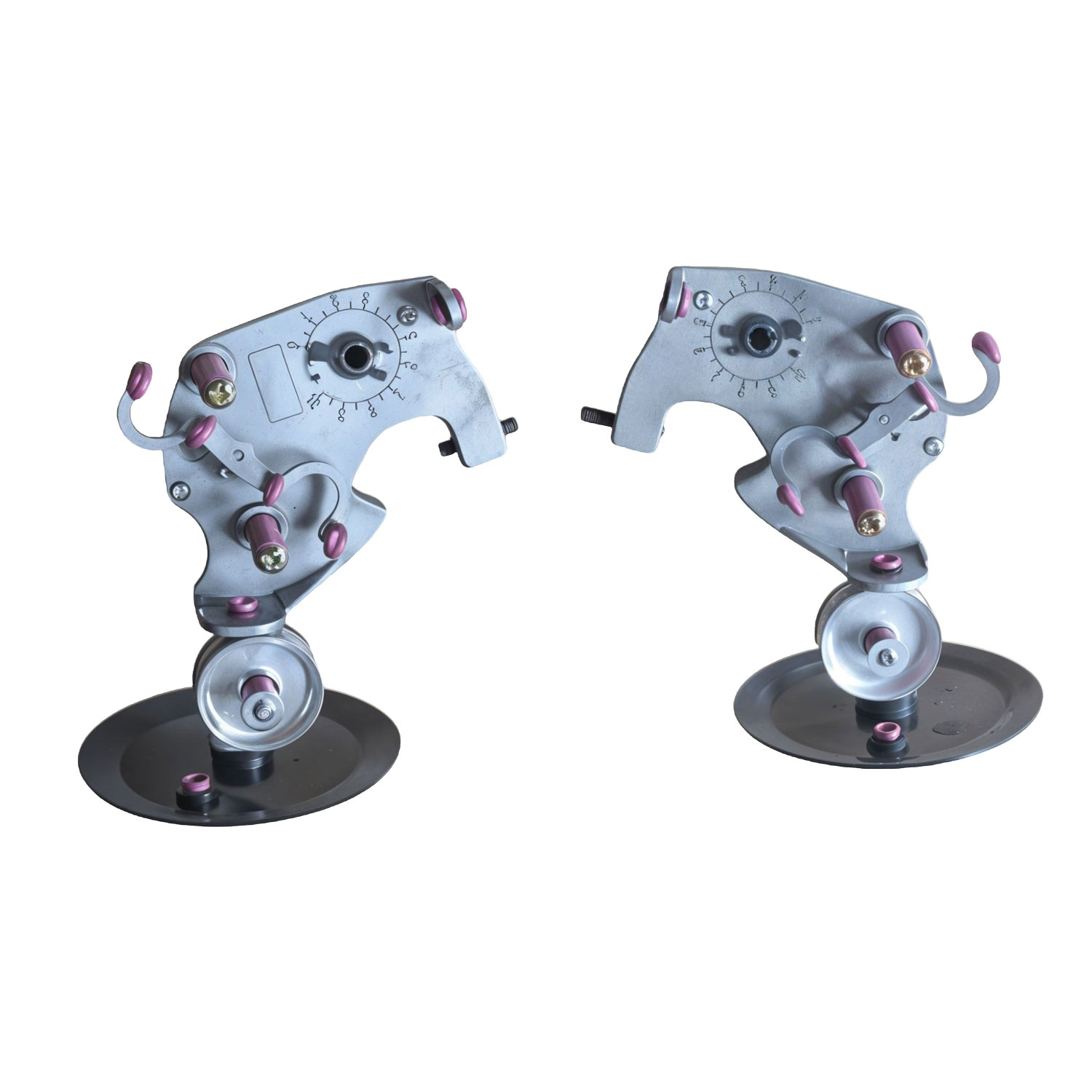

| Reed Needle For Warping Machine | |

| Model No. | E22/E24/E26/E28/E30/E32/E34 |

| Application | For Detecting Yarn Drop / Break |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

Premium Warping Machine Reed Needle – Superior Durability & Compatibility

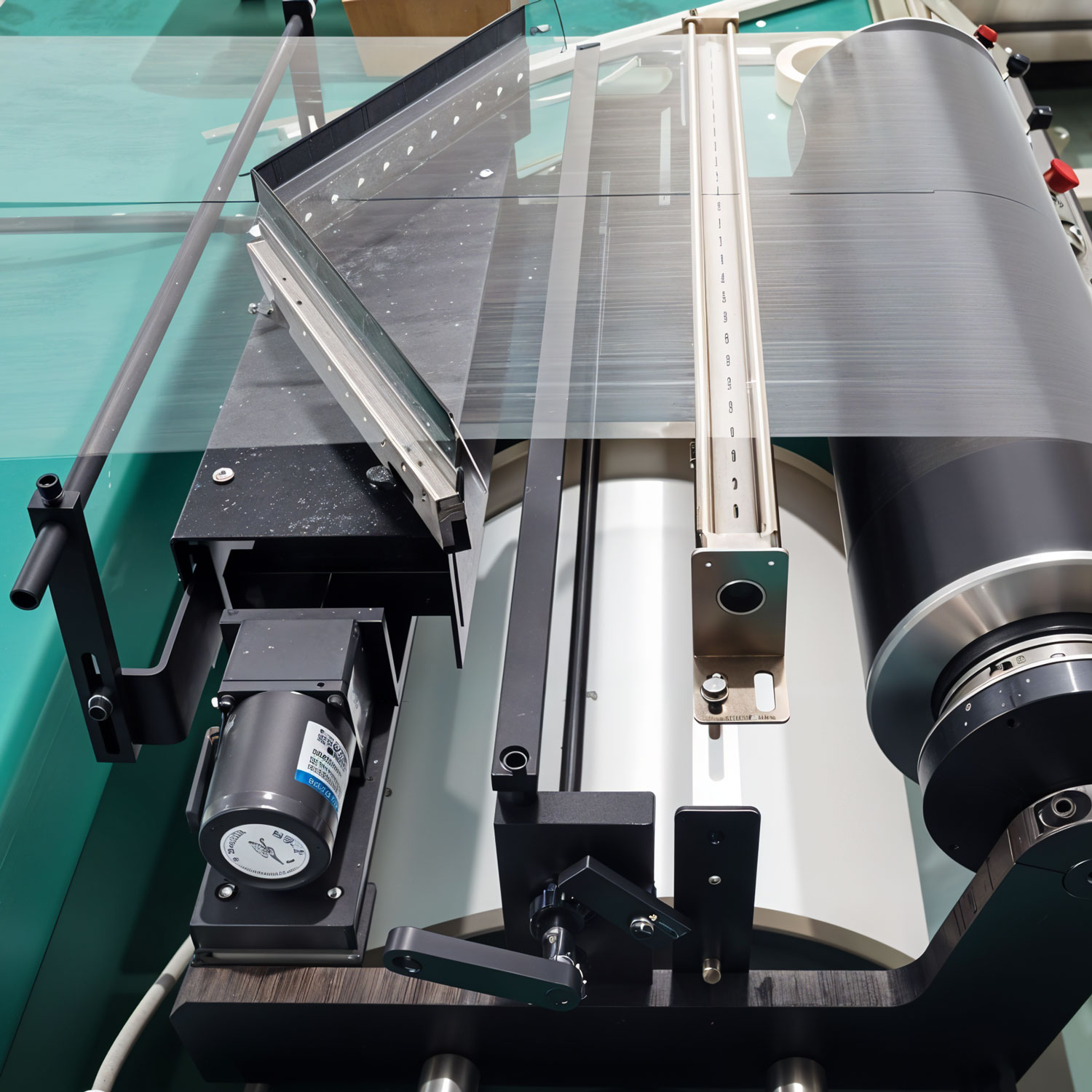

In warp knitting, the quality of warping machine reed needles is crucial for achieving high-precision yarn alignment and long-term machine performance. At [Company Name], we specialize in providing high-performance R-type reed needles designed for direct warping machines, split warping machines, and spandex warping machines.

Precision Engineering for Optimal Performance

Our reed needles are available in a wide range of gauges, including 22, 24, 26, 28, 30, 32, 34, and more, ensuring compatibility with various warping requirements.

Unlike standard alternatives, our reed needles feature premium electroplating technology, enhancing durability and resistance to wear. This advanced surface treatment extends the lifespan of the needles while ensuring smoother yarn guidance, reducing friction, and minimizing the risk of yarn breakage.

Unmatched Material Quality & Customization

To meet diverse industry demands, we offer two quality options:

- Standard tin-coated needles – A cost-effective solution for standard applications.

- Enhanced tin-coated needles – Featuring higher-grade tin plating for superior resistance to oxidation and corrosion, ideal for high-speed, long-duration operations.

Compared to competitors, our needles provide a more consistent finish, reducing machine downtime and maintenance costs while optimizing the efficiency of warping processes.

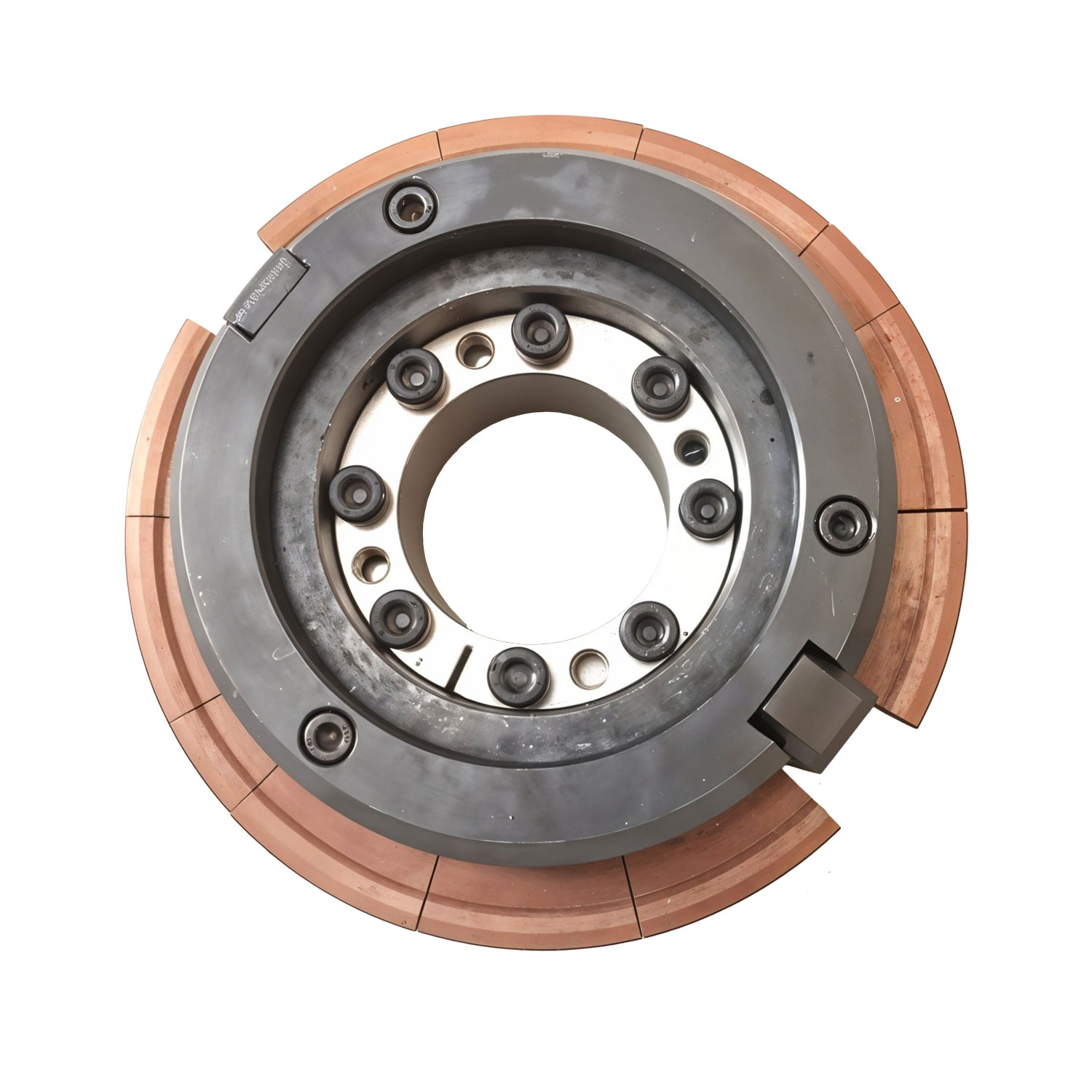

Seamless Compatibility with Leading Warping Machines

A key advantage of our warping machine spare parts is their broad compatibility. Our reed needles are designed to seamlessly fit both Chinese-brand warping machines and Karl Mayer warping machines.

Whether you operate a domestic or imported machine, our precision-engineered components guarantee smooth integration and enhanced operational stability.

Upgrade Your Warping Process Today

By choosing our high-quality warping machine reed needles, manufacturers can achieve superior warping precision, longer service life, and improved machine efficiency— giving them a competitive edge in the textile industry.

Application

- Electronics Manufacturing: Crucial for identifying areas of static electricity that can harm intricate circuits or equipment during construction or during the performance of tests.

- Pharmaceuticals: Assists in assuring that static electricity does not cause any problems with either the production of drug products or packaging.

- Textile Industry: Ideal for observing static in manufacturing processes of textiles to avoiding formation of defects in the fabrics or harm to equipment.

- Packaging: Essential especially when the packaging material is sensitive to static such as foodstuff and even in microchippers.

- Clean Rooms: Makes sure that the flow of static electricity is well controlled in clean places, which can affect product performance or contaminate it in case of any little charge.