How Warp and Weft Knitting Machines Benefit Seamless Innovation

Knitting technology has revolutionized the textile industry, enabling the production of diverse fabrics. Factories rely on advanced knitting machines to manufacture clothing, home textiles, and other essential products. But how exactly do these machines operate?

Seamless innovation is crucial in fabric production, enhancing speed, efficiency, and overall fabric quality. Many industries demand textiles that are durable, soft, and flexible. But how do knitting machines contribute to meeting these needs?

Warp and weft knitting machines are integral to modern textile manufacturing, ensuring smooth and efficient production. But what sets them apart? Let’s explore their mechanisms and significance in the industry.

Understanding Warp and Weft Knitting

Key Differences Between Warp and Weft Knitting

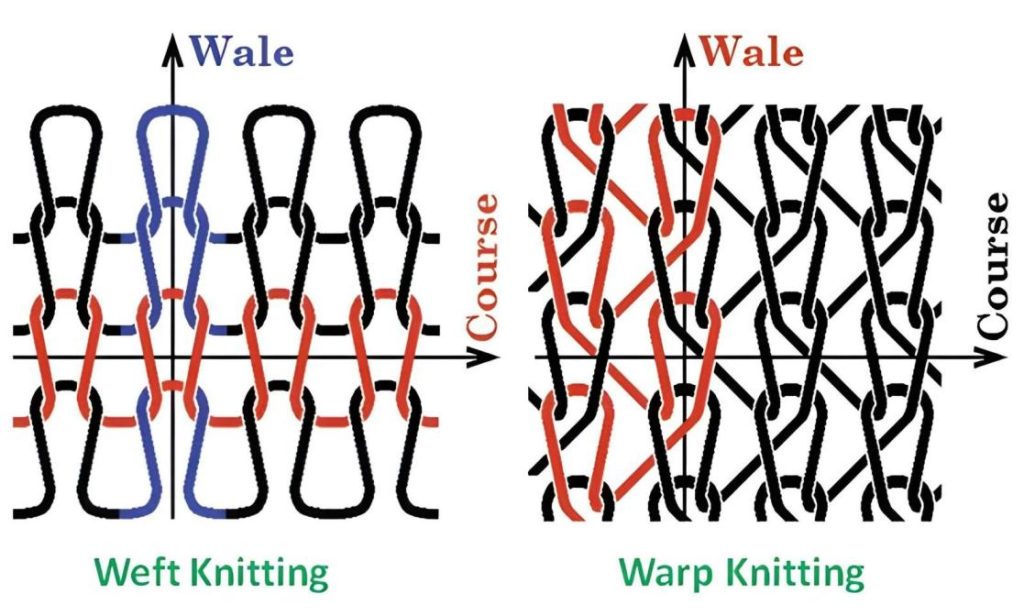

Warp and weft knitting are two important ways to make fabric. Each one has its own method. Each one creates a different type of fabric. Warp knitting uses many yarns at the same time. The yarns run up and down. This makes the fabric strong and stable. It does not stretch much. It is good for making lace, swimwear, and sportswear. Weft knitting uses one yarn at a time. The yarn moves side to side. This makes the fabric soft and stretchy. It is good for T-shirts, sweaters, and socks.

How Each Technique Contributes to Fabric Structure and Quality

Warp and weft knitting create fabrics with different qualities. Warp knitting makes firm and durable fabrics. The fabric holds its shape well. It does not easily unravel. It is great for making clothes that need to last. Weft knitting makes fabrics that stretch and feel soft. The fabric fits the body well. It is comfortable to wear. But it can lose shape over time. It can also unravel if a stitch is broken. Both types of knitting are useful. They help create different fabrics for different needs.

Advantages of Warp and Weft Knitting Machines

Enhanced Efficiency and High-Speed Production

Warp and weft knitting machines make fabric quickly. Factories can produce large amounts of fabric in less time. This helps meet high demand. It also lowers costs. Hand knitting is slow, but machines work fast. Warp knitting machines use many yarns at once. This speeds up the process. Weft knitting machines also work faster than hand knitting. Both machines help save time and effort.

Improved Fabric Durability, Elasticity, and Comfort

Warp and weft knitting machines make strong and comfortable fabrics. Warp knitting makes durable fabrics that last a long time. The fabric does not lose shape easily. It stays firm even after many washes. Weft knitting makes soft and stretchy fabrics. The fabric moves with the body. This makes it good for everyday wear. It is often used for casual and sports clothing.

Versatility in Textile Applications

Warp and weft knitting machines create many types of fabrics. Factories use them for clothing, home textiles, and industrial fabrics. Warp knitting is great for lace, mesh, and technical fabrics. Weft knitting is good for T-shirts, socks, and sweaters.

Grand Star’s Innovative Product

Grand Star has designed advanced knitting machines. These machines help factories produce high-quality fabrics. The Tricot Machine with Weft Insertion is one of its top products. It includes several modern features that improve speed, accuracy, and efficiency.

Tricot Machine with Weft Insertion

The individual needle bar is built for precision. It uses compound needles that help create smooth and even fabrics. These needles ensure that every stitch is strong and accurate.

The slider bar has plate slider units (½”). This feature helps control the movement of the knitting process. It allows for better stitch formation. The machine’s fabric take-up system is electronically controlled. A geared motor with four rollers moves the fabric smoothly. This system keeps the fabric in place while knitting.

Sinker Bar and Guide Bars

The sinker bar has compound sinker units. This ensures that the fabric remains stable while knitting. It helps prevent loose stitches and keeps the fabric uniform.

The guide bars control the yarn during knitting. They are made from carbon-fiber-reinforced materials. These materials are lightweight but very strong. They also reduce the weight of the machine. This makes the machine more efficient and long-lasting.

Weft-Insertion System and Yarn Let-Off Device

The weft-insertion system has a yarn-laying carriage. This carriage holds 24 yarn ends. It helps insert yarn smoothly and evenly into the fabric. The yarn let-off device ensures that the yarn feeds evenly. Each warp beam position has an electronically controlled let-off drive. This keeps the yarn at a uniform tension. It helps create consistent fabric quality.

Operator Interface (GrandStar® Command System)

The GrandStar® Command System allows operators to control the machine easily. It lets them adjust settings and monitor performance. They can configure all electronic functions without difficulty. This makes operation simple and user-friendly.

Batching Device and Pattern Drive

The batching device is a separate, floor-standing cloth rolling unit. It helps collect the fabric efficiently. This keeps the finished fabric organized and ready for further processing. The pattern drive system offers two options. The N-Drive has three pattern discs. It also includes a tempi change gear, which allows easy pattern adjustments. The optional EL-Drive has three electronically controlled motors. These motors allow all guide bars to move up to 50 mm. For special fabrics, the machine can extend up to 80 mm.

Impact on Various Industries

Grand Star’s advanced knitting machines help many industries. The fabrics produced are used in clothing, home textiles, and technical applications.

Fashion and Sportswear: Performance and Aesthetics

Fashion and sportswear need fabrics that look good and perform well. These fabrics must be soft, flexible, and breathable. Warp and weft knitting machines create strong yet comfortable textiles. Sportswear fabrics must also handle sweat and movement. Grand Star’s machines help make these fabrics quickly and efficiently.

Home Textiles: Strength and Softness Combined

Home textiles include bedsheets, curtains, and upholstery. These fabrics must be strong but also soft. Warp knitting machines make durable fabrics that last for years. Weft knitting machines create soft and stretchable fabrics. Grand Star’s machines allow manufacturers to make high-quality home textiles in large amounts.

Technical Textiles: Innovation in Medical and Industrial Fabrics

Technical textiles are used in medical and industrial fields. Medical fabrics need to be clean, breathable, and durable. Industrial fabrics must handle high pressure and wear. Grand Star’s machines create fabrics with high precision. These fabrics are used in hospitals, factories, and outdoor gear.

The Role of Technology in Seamless Innovation

Modern technology has improved knitting machines. Automation and smart systems help factories work faster and better.

Automation and Smart Knitting Machines

Automation makes knitting machines more efficient. Grand Star’s machines have advanced features for accuracy. The Laserstop system detects faults quickly. It stops the machine if there is an error. This prevents defects and reduces waste. The integrated camera monitors fabric quality. It ensures that every piece meets high standards. This helps factories maintain consistency.

Sustainability and Eco-Friendly Fabric Production

Sustainability is important in textile production. Factories need machines that use less energy and create less waste. Grand Star designs machines that are energy-efficient. These machines reduce fabric waste and use eco-friendly materials. Knitting technology is improving every day. Grand Star’s machines help factories produce high-quality fabrics while saving time and resources.

Upgrade Your Production with Grand Star’s Knitting Machines!

Grand Star makes advanced knitting machines. They help factories work faster and better. These machines create high-quality fabrics. The Tricot Machine with Weft Insertion has many useful features. It makes fabric strong, smooth, and even. It has a smart control system. It is easy to use. It saves time and reduces waste.

Many industries use these machines. They make fabrics for clothes, home textiles, and technical use. Strong fabrics last longer. Soft fabrics feel better. Improve your production today. Choose Grand Star. Get faster, better, and smarter knitting. Contact us now!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.