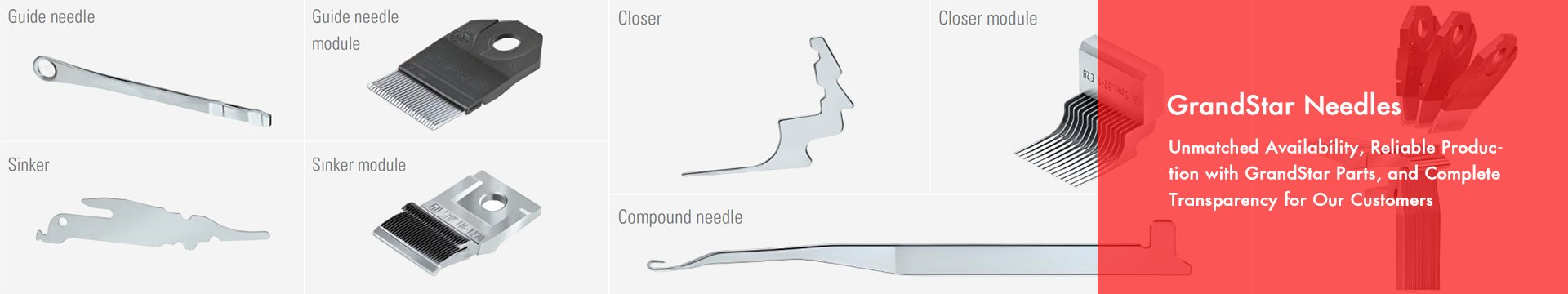

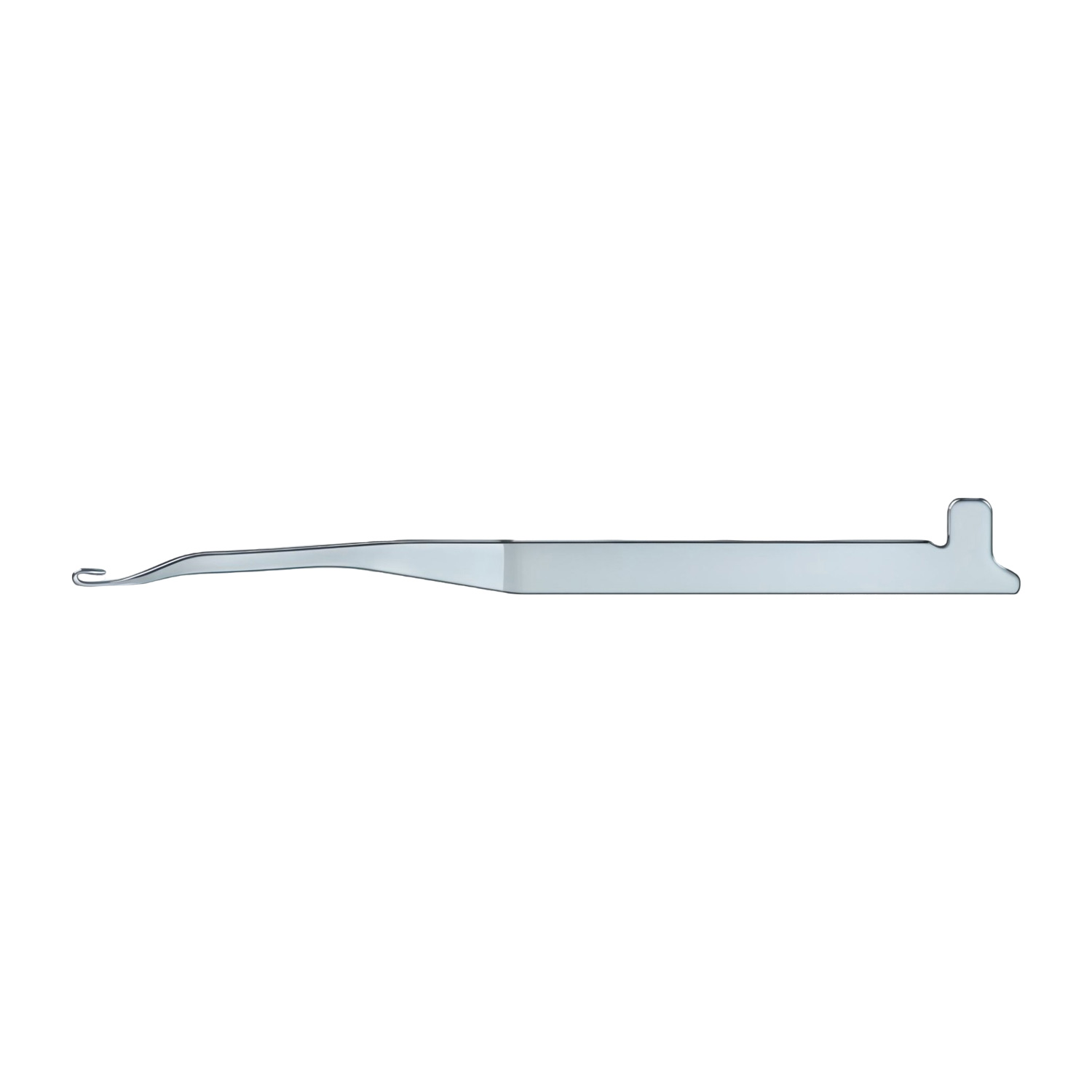

Closer Needle (Core Needle)

| Closer Needle (Core Needle) For Warp Knitting Machine | |

| Model No. | C-XX-XX |

| Place of Origin | Fujian, China |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- PRODUCT LIST

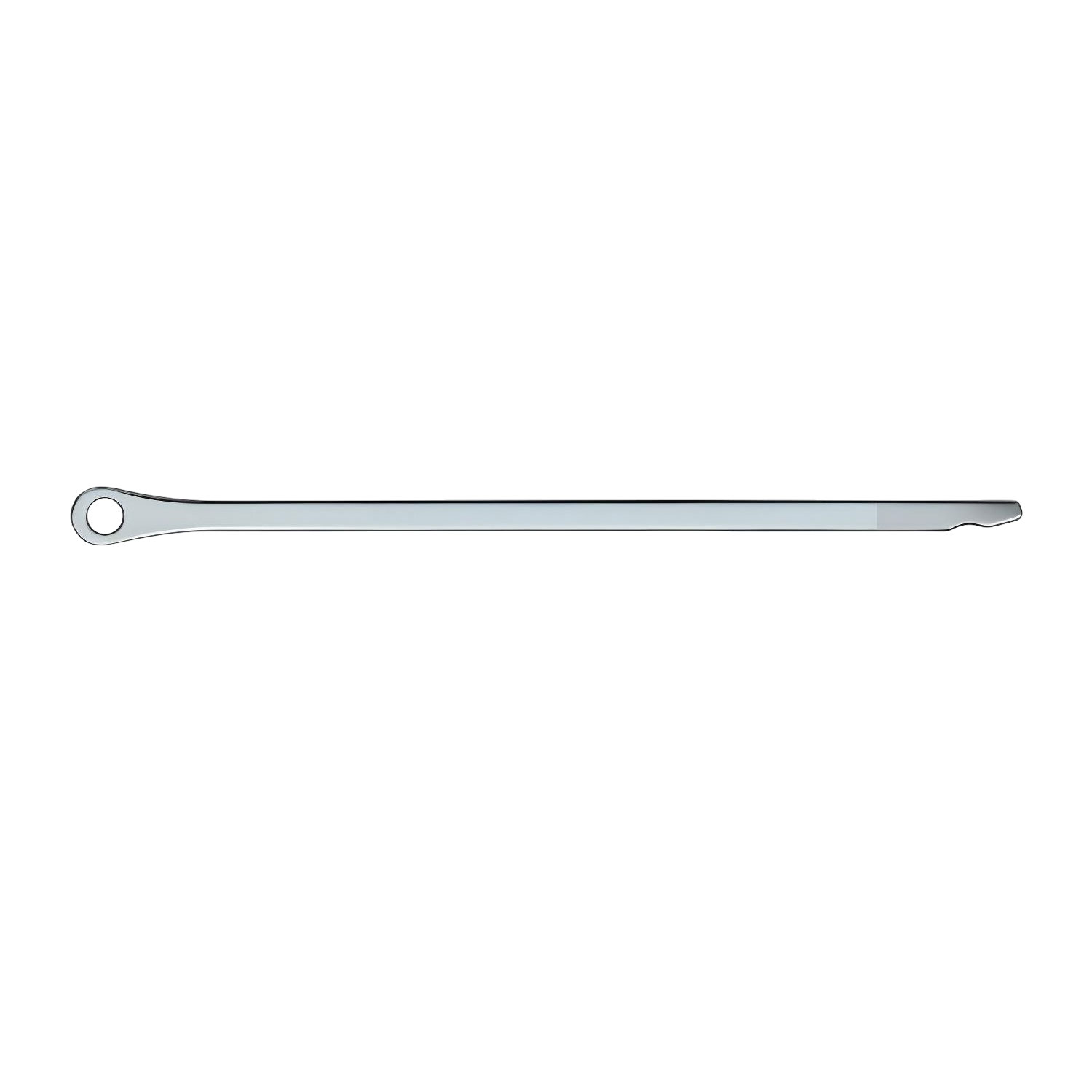

High-Precision Closer Needles: Elevating Warp Knitting Quality

Closer needles are essential components in warp knitting, playing a crucial role in fabric quality and production efficiency. These high-precision needles are designed with meticulous engineering, featuring a needlepoint and a carefully structured needle body. The body has a narrow upper section and at least two broader sections fixed closely together, creating a robust connection. This connection is securely affixed to the needle bed, while the narrow section moves smoothly within the needle groove, ensuring flawless operation.

These needles are built for superior strength and durability, resistant to wear and tear, and capable of withstanding demanding production environments. Their exceptional precision is critical to achieving consistent, high-quality results in warp knitting processes.

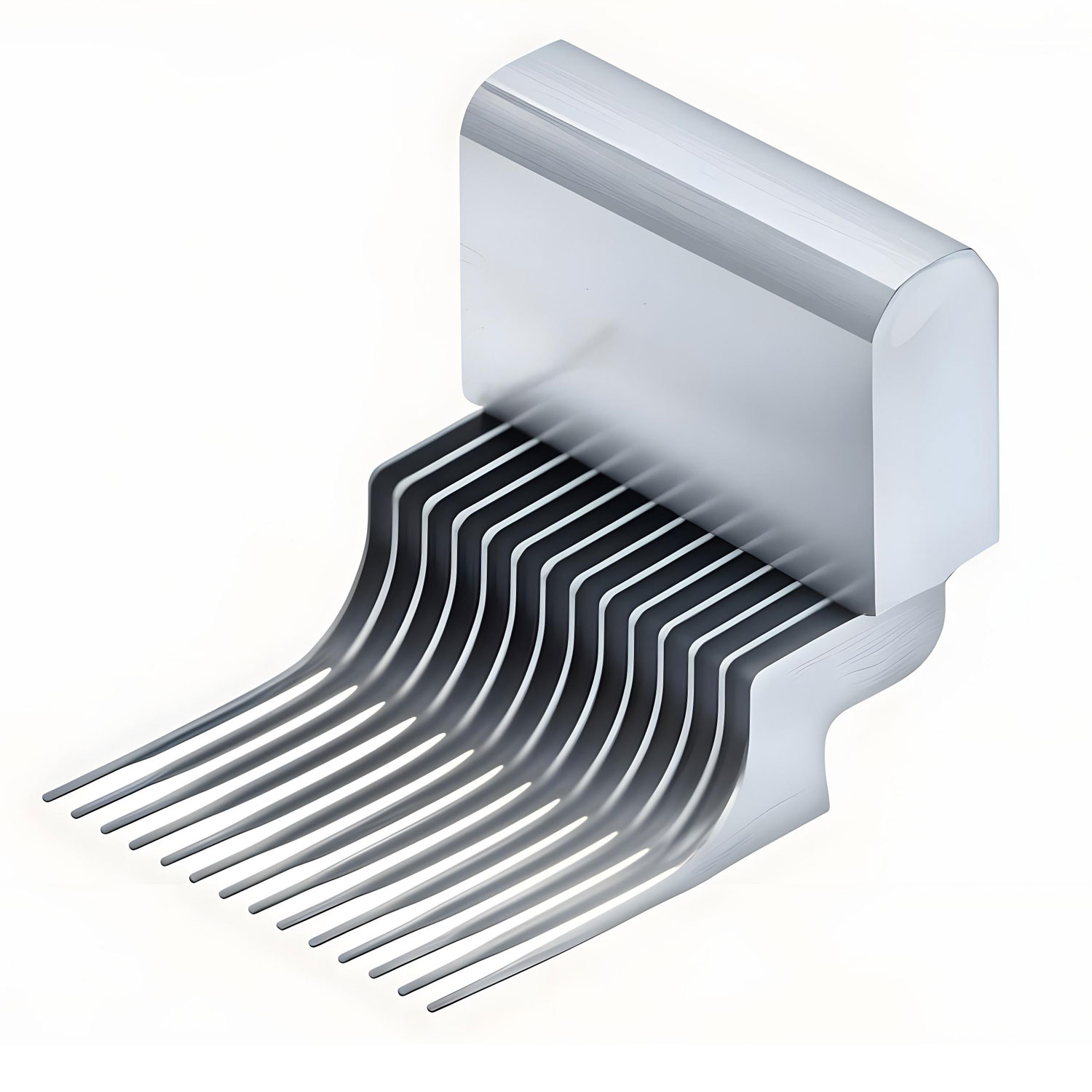

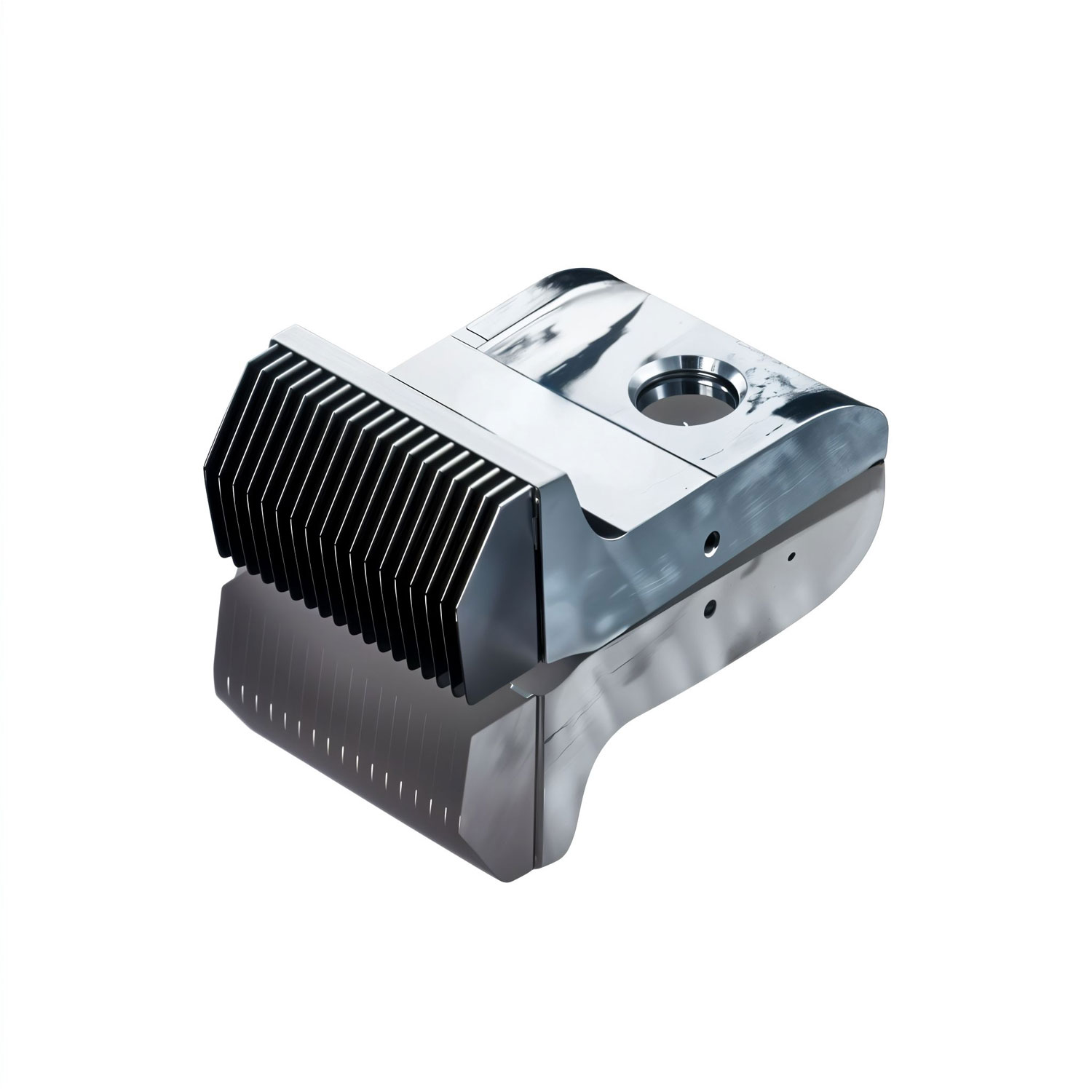

Closer Modules: Ensuring Precision in Loop Formation

Closer modules are among the most sophisticated components in warp knitting machinery. They must be precisely adjusted on the bar and accurately aligned within the needle slot to maintain consistent loop formation. Even minor deviations in positioning or alignment can lead to irregular loops, increased straightening processes, and premature wear of both the closer and needle slot.

The importance of these modules lies in their role in producing smooth, uniform loops and maintaining fabric integrity. Their precision directly influences both production efficiency and the overall quality of the knitted fabric.

Application

- Warp Knitting Machines: Essential for achieving consistent loop formation and high-quality fabric in warp knitting operations, especially in high-performance machines like KARL MAYER and LIBA.

- Textile Manufacturing: Crucial for the production of knitted fabrics, including sportswear, lingerie, and technical textiles that require precision in loop formation and consistent quality.

- Apparel Production: Used in the production of fabrics that require fine detailing and durability, such as activewear and seamless garments.

- Industrial Textiles: Perfect for producing strong, functional fabrics for use in automotive, upholstery, and other industrial applications.

- Custom Applications: Tailored solutions for specialized machinery or niche industries requiring specific needle and module configurations.