Detect-Scan System

| Category | Solutions |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

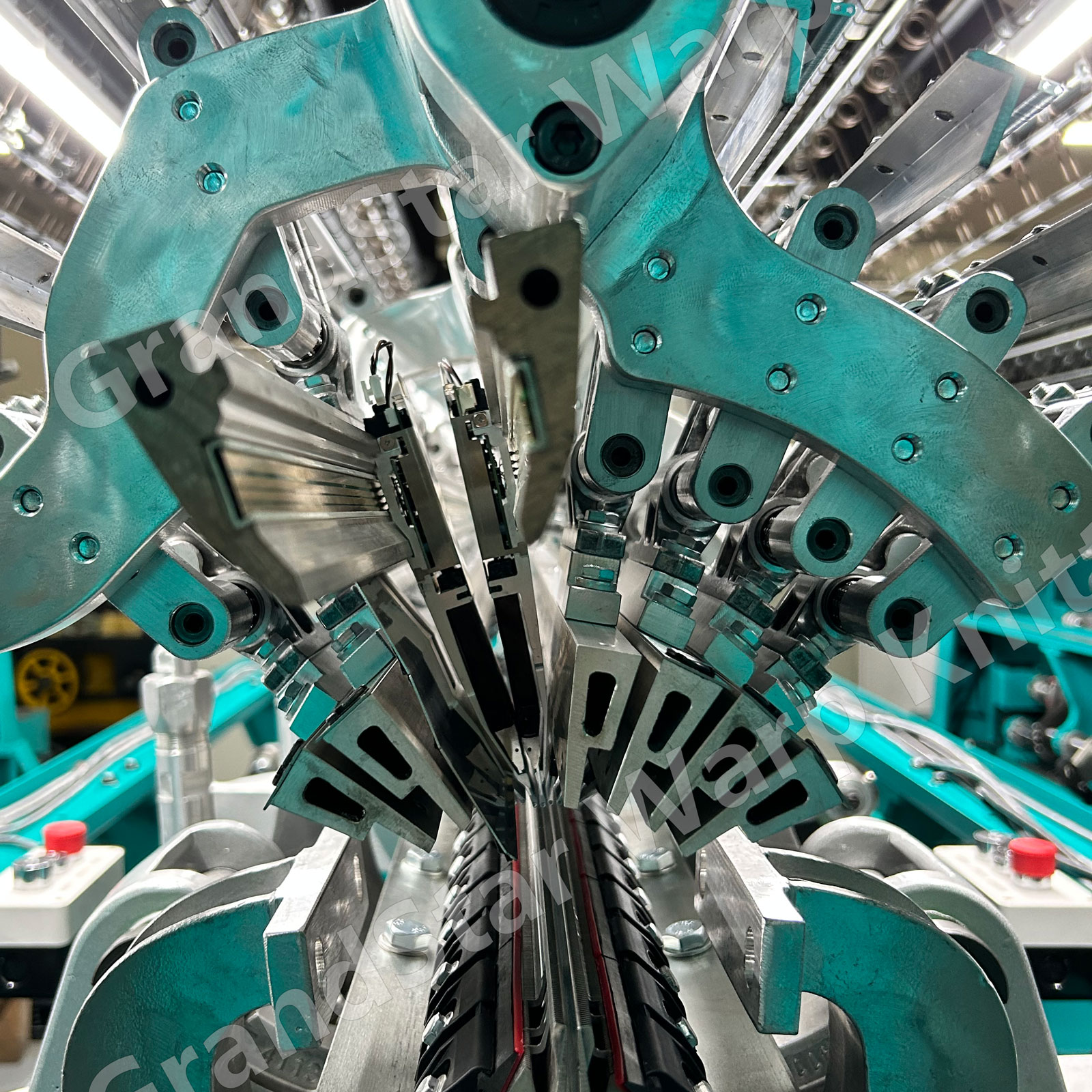

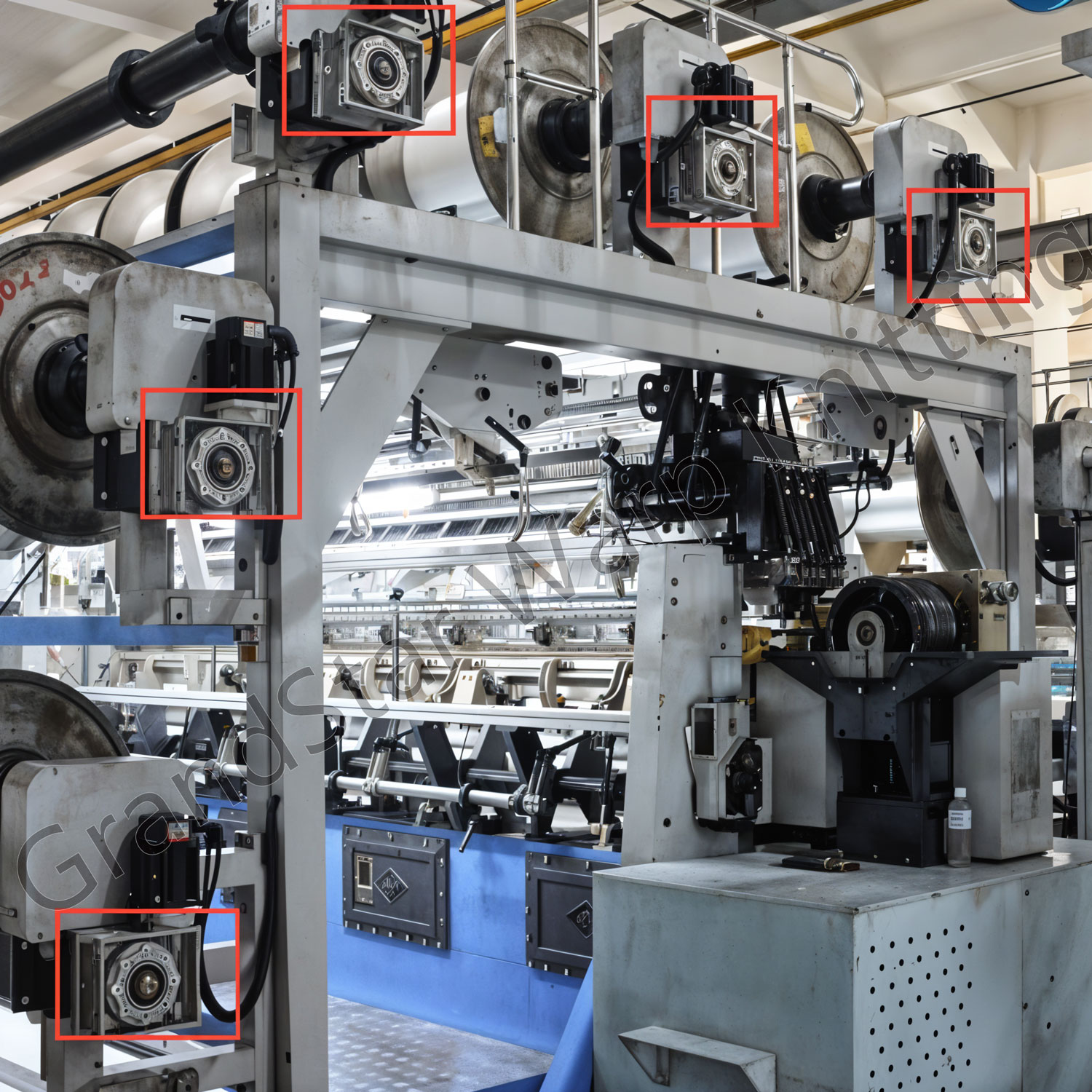

The Procam System for Tricot machines is an automatic optical inspection solution designed to ensure flawless fabric production by identifying defects with unparalleled speed and precision.

Technical Features:

- Working Widths: 0–100 cm (with 1 camera).

- Reaction Time: Less than 100 milliseconds, ensuring rapid detection and response.

- Light Source: LED lighting for clear visibility and accurate defect identification.

- Power Supply: 220V single-phase operation.

- Outputs: Relay contact output (6 groups).

- Built-In Laserstop: Equipped with 1–4 laser groups for enhanced safety and stopping accuracy.

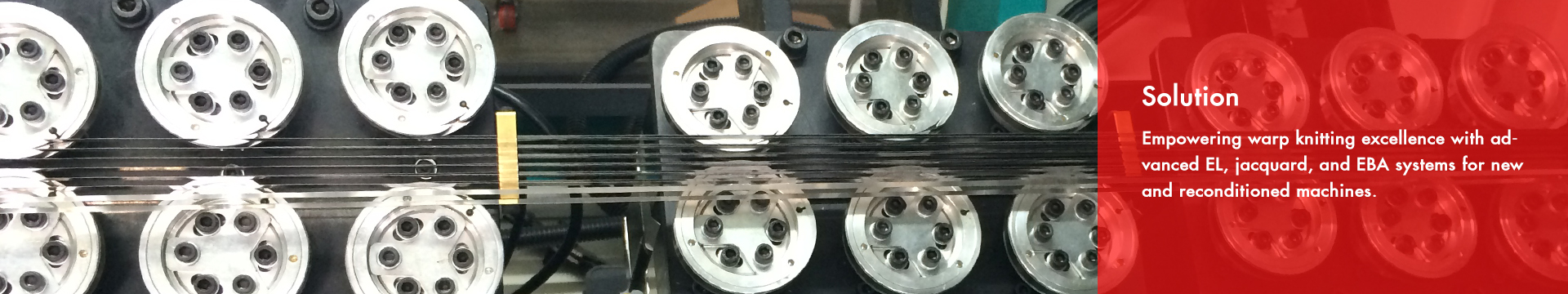

Procam System for Warping Machines

The Procam System for warping machines is specifically tailored for precise yarn monitoring, enabling efficient and accurate detection of inconsistencies during warp preparation.

Technical Features:

- Working Width: Up to 60 cm.

- Detectable Yarn Diameter: 15D (denier).

- Compatible Yarn Colors: White and black.

- Warp Speed: Up to 100 m/min.

- Reaction Time: Less than 0.2 seconds for quick fault detection.

- Maximum Yarn Count: Supports monitoring of up to 1,000 yarns simultaneously.

- Output: Dry contact interrupter output for reliable integration.

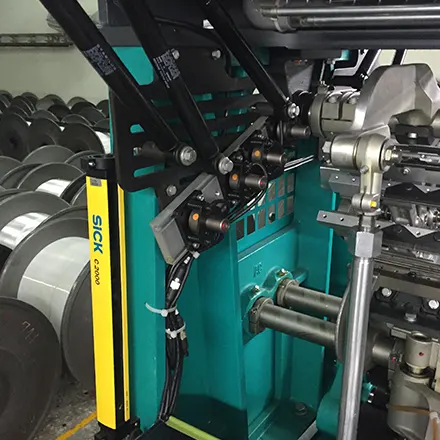

Procam System for Laserstop

The Procam System for Laserstop provides enhanced safety and detection for warp knitting machines, ensuring seamless production and minimizing risks associated with yarn breaks or faults.

Technical Features:

- Working Voltage: Single-phase 220V.

- Activating Voltage: Single-phase 220V.

- Working Width: 60–210 inches for broad machine compatibility.

- Detectable Yarn Diameter: 15D (denier).

- Adjustable Sensitivity: Controlled through a user-friendly panel.

- Laser Components: Configurable from 1–8 laser groups.

- Output: Relay contact output for seamless fault management.

- Fan Power (Optional): 750W for enhanced cooling performance.

Application

-

Warp Yarn Monitoring: Detects inconsistencies in yarn tension, color, and quality during the warping process, preventing downstream issues.

-

Safety Enhancement with Laserstop: Ensures machine safety by detecting yarn faults and activating immediate stop mechanisms, minimizing damage and material wastage.

-

High-Speed Production Monitoring: Enables real-time quality checks in high-speed operations, improving productivity and reducing downtime.

-

Broad Machine Compatibility: Applicable for warp knitting and warping machines of varying working widths and configurations, providing flexibility across textile operations.