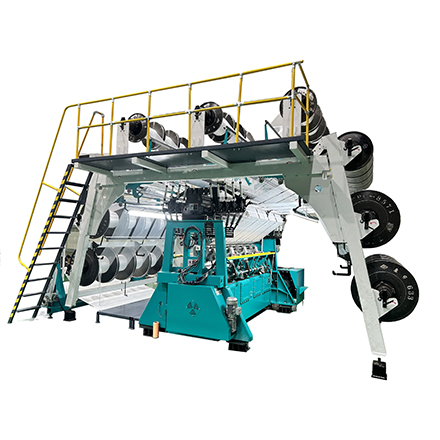

Double Needle Bar

Double needle bar raschel machines are advanced textile machines designed to create complex 3D fabrics. These machines combine precision engineering and the latest technology to produce a variety of textiles, including spacer fabrics and jacquard-patterned materials. They are particularly popular in industries that require high-quality, durable, and innovative fabrics, such as footwear, apparel, automotive, and home textiles. The versatility of these machines allows for the production of a wide range of products, from delicate lingerie fabrics to sturdy upholstery materials.

Key Features:

- Dual Needle Bars: The double needle bar design allows for the simultaneous use of two different yarns, enabling the creation of intricate and unique patterns.

- Jacquard Technology: This feature allows for detailed, custom designs to be woven into fabrics, such as 3D patterns and seamless textiles, providing a high level of creativity and precision.

- Spacer Fabric Production: These machines are ideal for producing spacer textiles, which are known for their thickness, comfort, and breathability.

- Clear Two-Color Layers: The technology used in these machines allows for clear two-color double layers, enhancing the fabric’s design and aesthetic appeal.

- Counter-Lapping Technology: This innovative technology improves fabric structure and functionality, ensuring durability and flexibility.

- Versatility: The machines can produce a wide variety of fabrics, from lightweight meshes to durable materials, making them suitable for many different applications.

Applications:

- Shoe Industry: Double needle bar raschel machines are widely used in the production of engineered mesh and performance footwear. The fabrics produced are breathable, lightweight, and provide high comfort, making them ideal for shoes.

- Home Textiles and Apparel: These machines enable the production of seamless fabrics and unique designs, which are perfect for stylish home textiles, such as curtains and cushions, as well as fashionable apparel like lingerie and activewear.

- Automotive Sector: Spacer textiles produced by these machines are increasingly used in automotive applications, particularly in seats and upholstery. Their air-circulating properties enhance comfort and durability, making them a preferred choice for car interiors.

- Mattresses and Furniture: The ergonomic and breathable properties of spacer textiles make them ideal for use in mattresses, chairs, and other furniture items. They help improve comfort and durability, meeting the needs of modern consumers.