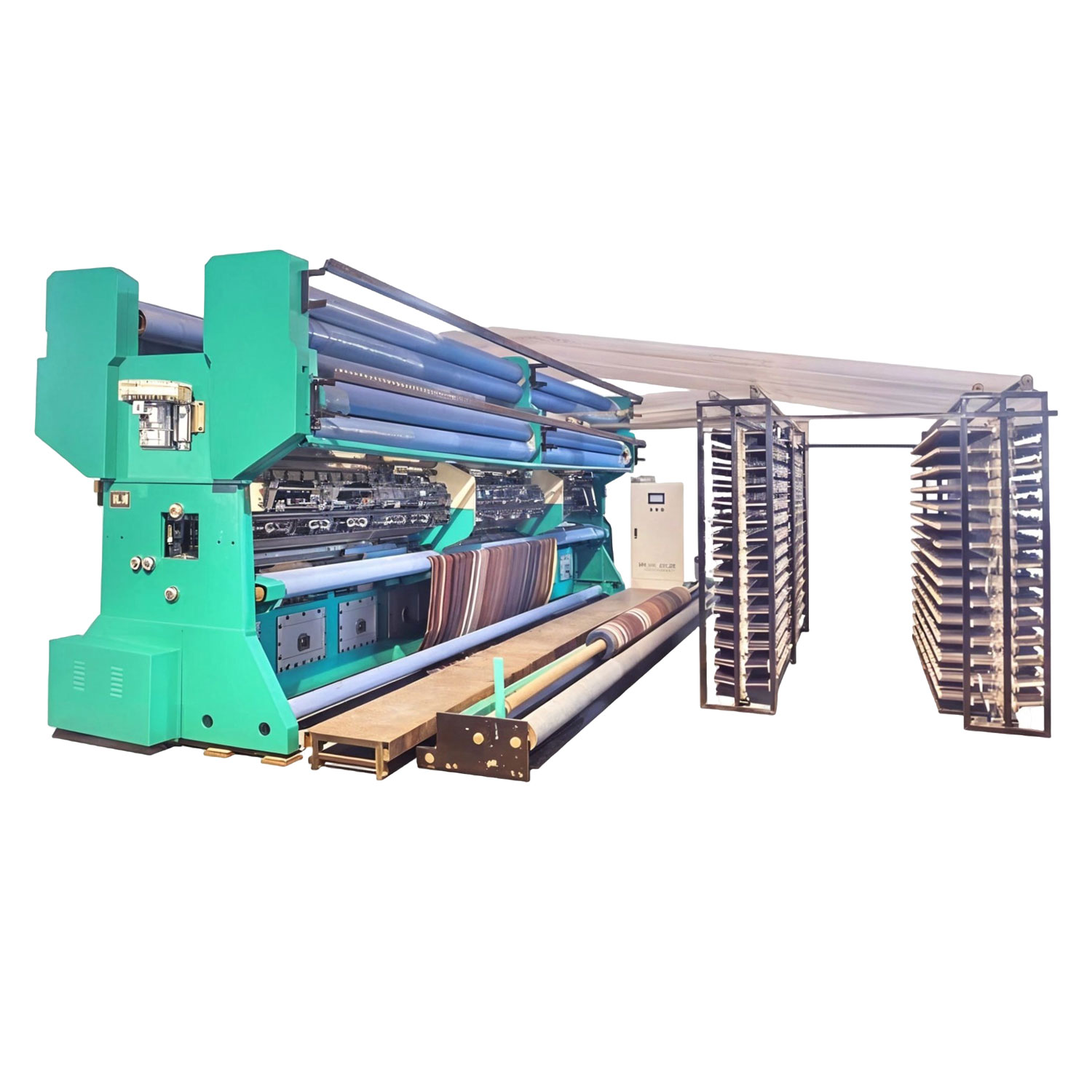

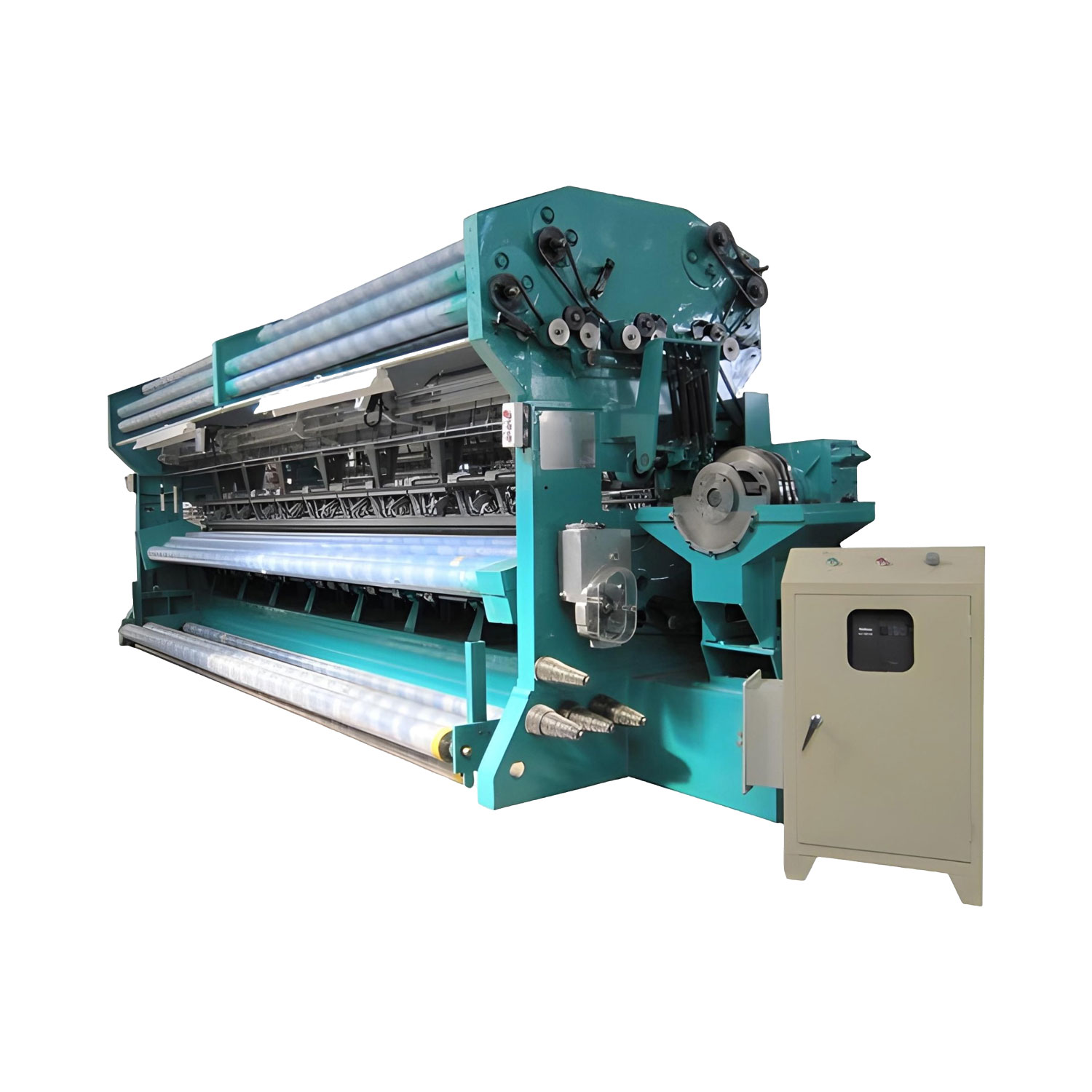

Double Needle Bar Raschel For Net

| Double Needle Bar Raschel Machine For SunShade/Vegetable Net – Warp knitting Machine | |

| Model No. | GS-RDS-EL |

| Ground Bars | 4/6/8/9 Bars |

| Gauge | E2/E3/E6/E9/E12/E18 |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

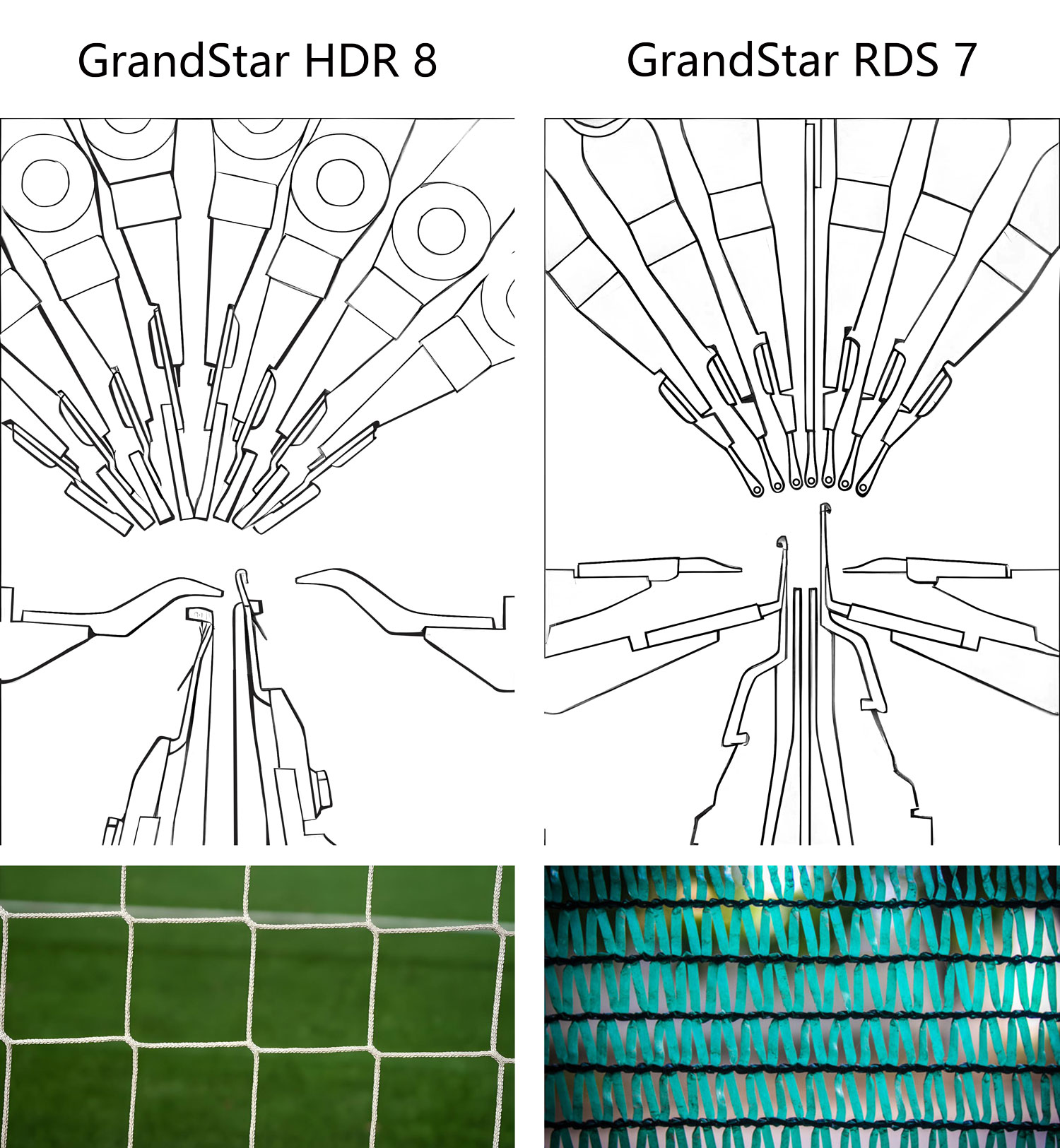

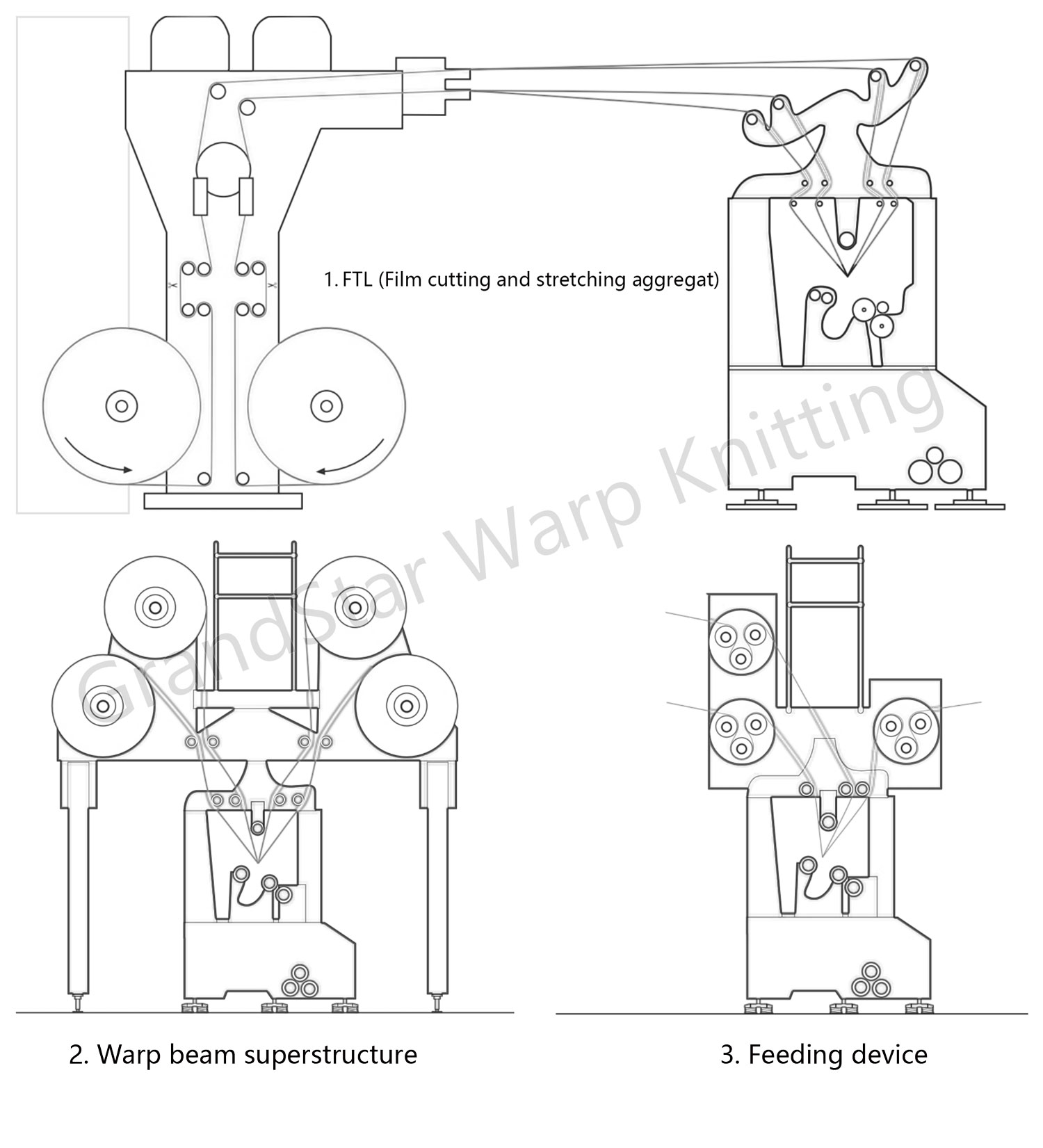

- TECHNICAL DATA

- TECHNICAL DRAWINGS

Working Width & Gauge

- Working Width Options:

- 3302 mm = 130″

- 4572 mm = 180″

- 5334 mm = 210″

- 6502 mm = 256″

- Gauge Options: E2, E3, E6, E9, E12, E18

Knitting Elements

- Bars:

- Two needle bars with latch needle units

- Two knock-over comb bars

- Two movable stitch comb bars

- Available configurations: 4, 6, 8, or 9 ground bars

Warp Beam Support

- Positions: 4/6/8/9 × 812 mm = 32″ (free-standing)

Control System

- GrandStar® COMMAND SYSTEM:

- User-friendly operator interface to configure, control, and adjust the machine’s electronic functionality

Yarn Let-Off Device

- One electronically controlled yarn let-off drive for each fully mounted warp beam position

Fabric Take-Up System

- Electronically regulated, driven by a geared motor, consisting of four rollers

Batching Device

- Separate rolling device for fabric batching

Electrical Equipment

- Drive: Speed-regulated

- Total Connected Load: 7.5 KW

- Voltage: 380V ±10% three-phase power supply

- Power Cord Requirements:

- Main power cord: Minimum 4m², three-phase, four-core

- Ground wire: Minimum 6m²

Oil Supply

- Circulating air heat exchanger for heating and cooling

- Equipped with a dirt-monitoring filter system

Equipment Working Conditions

- Temperature: 25℃ ±3℃

- Humidity: 65% ±10%

- Floor Pressure: 2000–4000 KG/㎡

Training & Service

Installation & Training

Training for warp knitting machines is offered globally through videos, manuals, online guidance, and on-site programs, backed by local teams in Turkey, India, Vietnam, Indonesia, and the USA.

Local Service

Grandstar ensures machine longevity with on-site services across Turkey, India, Vietnam, Indonesia, and the USA, combined with professional maintenance routines.

Application

- Automotive Industry: Spacer textiles for seats, headrests, and upholstery that enhance comfort and durability.

- Footwear Industry: High-quality engineered mesh and spacer fabrics for lightweight and breathable shoe uppers.

- Home Textiles: Mattress and furniture materials with air-circulating properties for ergonomic designs.

- Sportswear: Stretchable and resilient fabrics for performance wear.

- Medical Sector: Spacer fabrics for bandages, orthopedic supports, and healthcare-related applications.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |