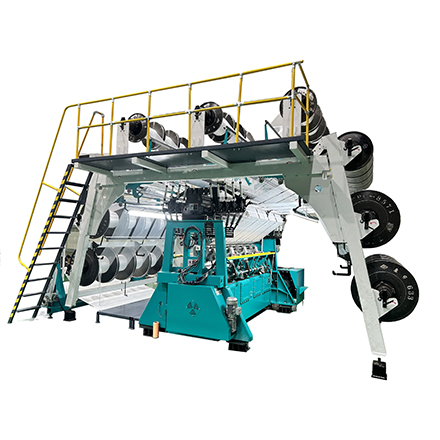

Double Raschel Jacquard Lace Machine 7/2

| Double Jacquard Double Needle Bar Raschel Machine – Warp Knitting Machine | |

| Model No. | GS-RDPJ 7/2 (EL) |

| Ground Bars | 5 Bars |

| Jacquard Bars | 4 Bar (2 Group) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

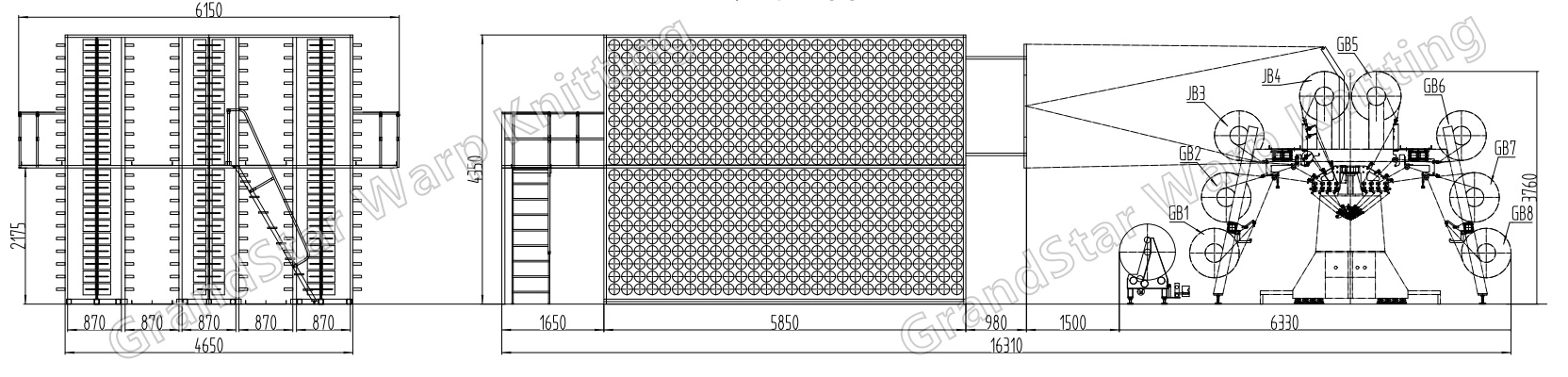

- TECHNICAL DRAWINGS

Working Width / Gauge

- Working Width: 3454 mm (136”)

- Gauge Options: E18, E22, E24, E28

Knock-Over Comb Bar Distance

- Adjustable range: 2–12 mm for versatile fabric production.

- Central trick plate with distance readjustment for precise configurations.

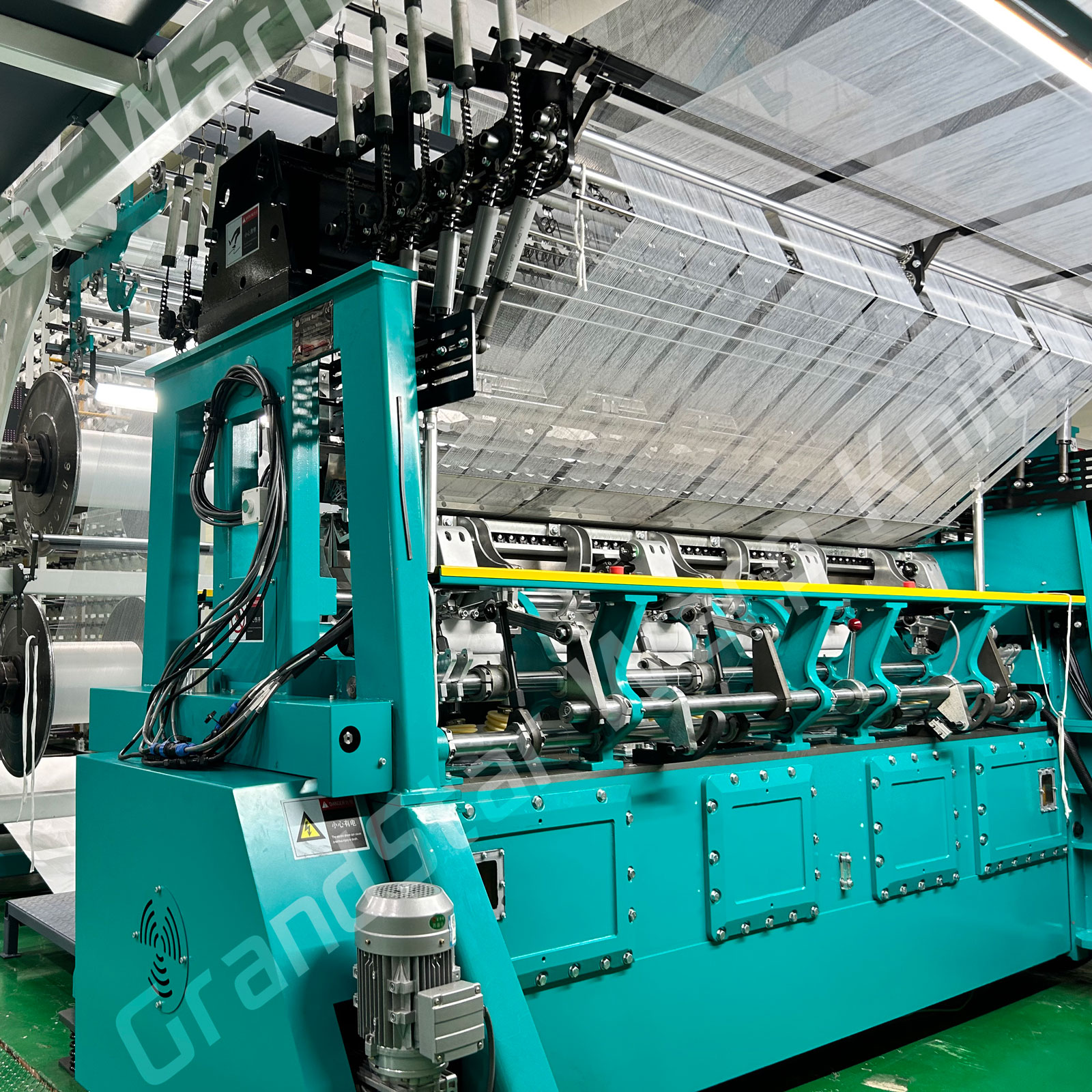

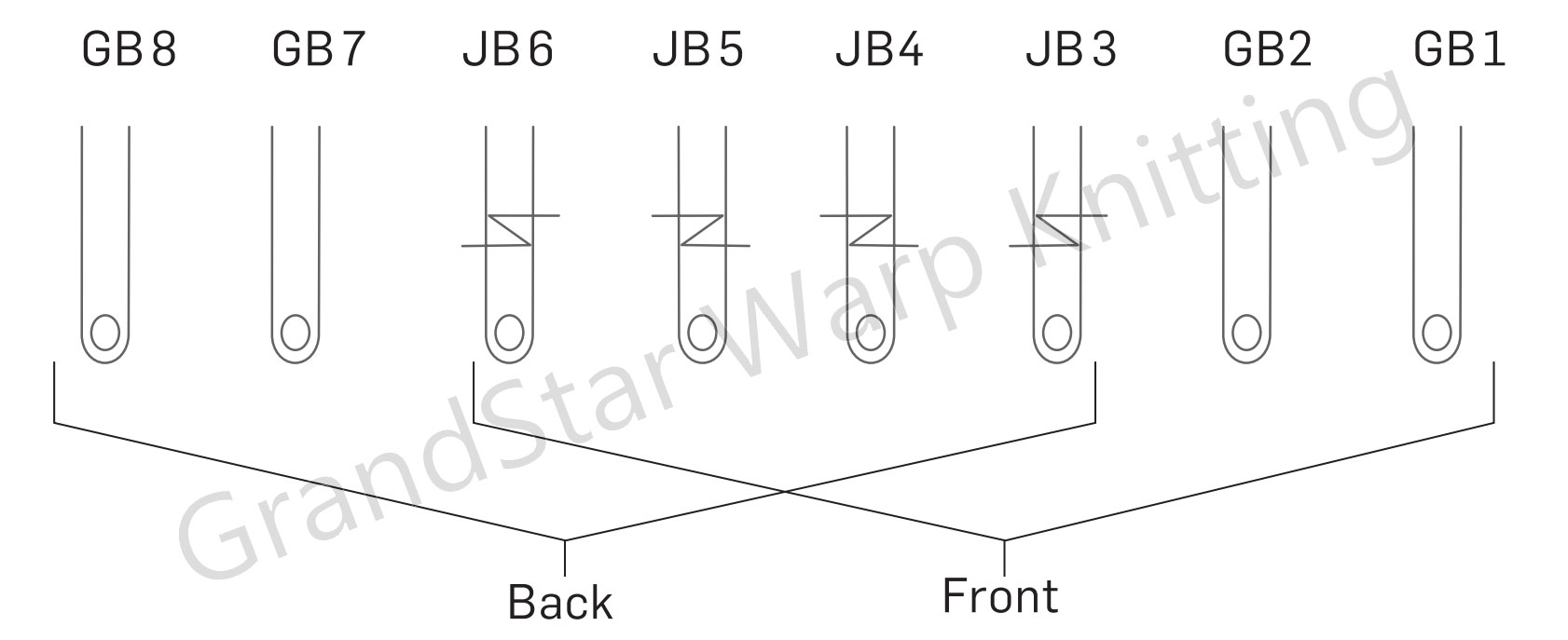

Knitting Elements and Bars

- Guide Bars:

- Six ground guide bars for detailed fabric formation.

- One Piezo-Jacquard guide bar with split execution for intricate jacquard designs.

- Stitch Forming:

- GB3, GB4, JB5, and JB6 stitch forming on both needle bars.

- Needle Bars:

- Two individual latch needle bars for enhanced flexibility.

- Comb Bars:

- Two knock-over comb bars and two stitch comb bars.

Warp Beam Support

- Capacity: Seven warp beams, each 812 mm (32”), free-standing for stability and operational efficiency.

Automation and Control

- GrandStar® Command System:

- Intuitive interface for configuring and managing electronic machine functions.

- Electronic Guide Bar Drive EL:

- Allows all guide bars to shog up to 150 mm, enabling precise pattern creation.

Fabric Handling Systems

- Yarn Let-Off Device:

- Electronically controlled let-off drive for each warp beam position ensures consistent tension.

- Fabric Take-Up:

- Gear motor-driven, electronically regulated system with four rollers for smooth and accurate fabric handling.

- Batching Device:

- Separate rolling device for efficient fabric batching.

Training & Service

Installation & Training

Technical support is a cornerstone of our warp knitting machine services. To ensure our customers maximize the performance of their machines, we provide comprehensive training programs in multiple formats.

Local Service

We have dedicated local after-sales service teams for Turkey, India, Vietnam, Indonesia and the USA and we are planning to expand our operations by opening more service stations in other countries in the near future.

Application

-

Mesh and Spacer Fabrics: Ideal for breathable materials used in sportswear, automotive interiors, and industrial applications.

-

Technical Textiles: Used in geotextiles, filtration materials, and reinforced fabrics for industrial purposes.

-

Lace and Decorative Textiles: High-quality lace for garments, home décor, and accessories.

-

Automotive Fabrics: Spacer fabrics and technical materials used in car seat covers, headliners, and acoustic panels.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |