EL System

| Category | Solutions |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

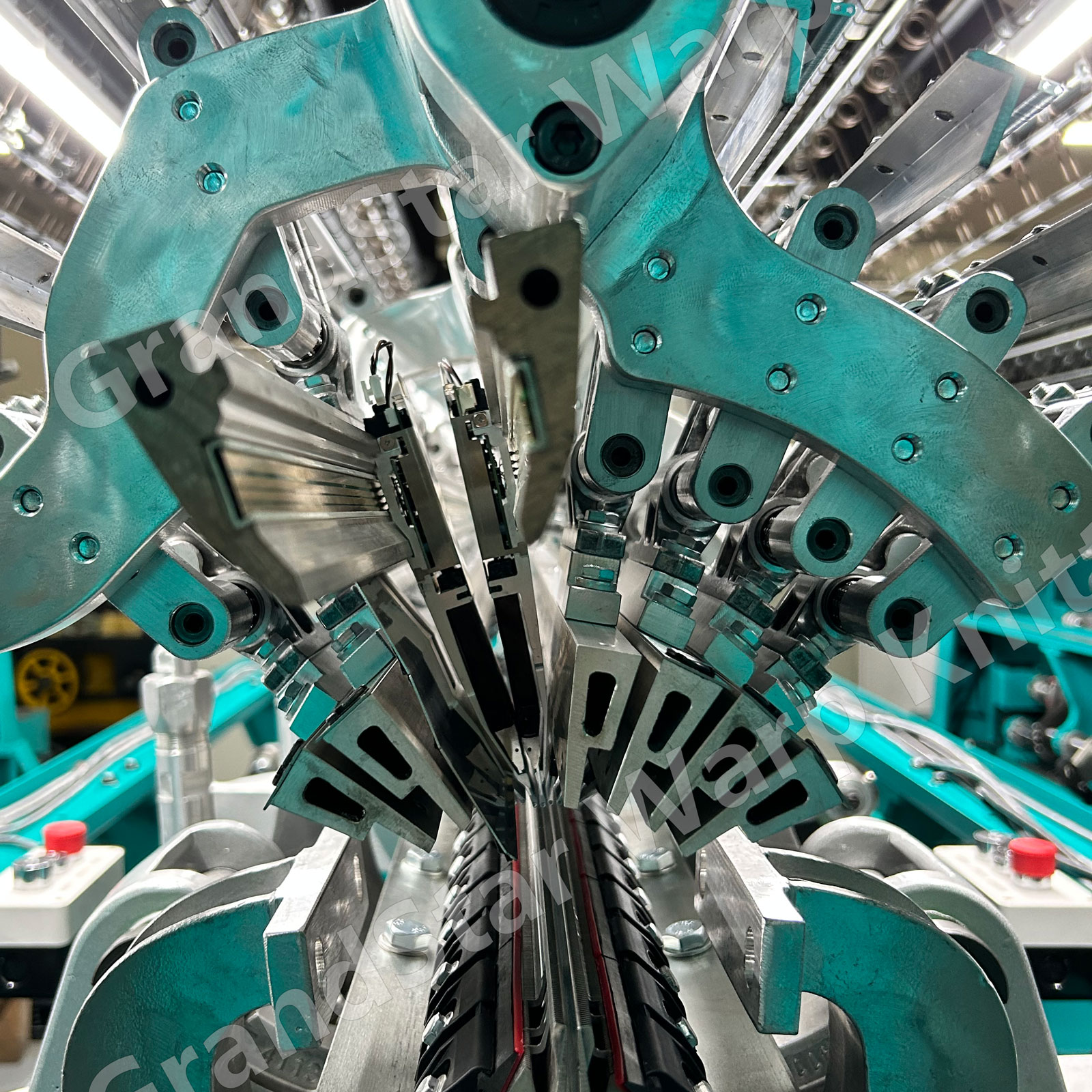

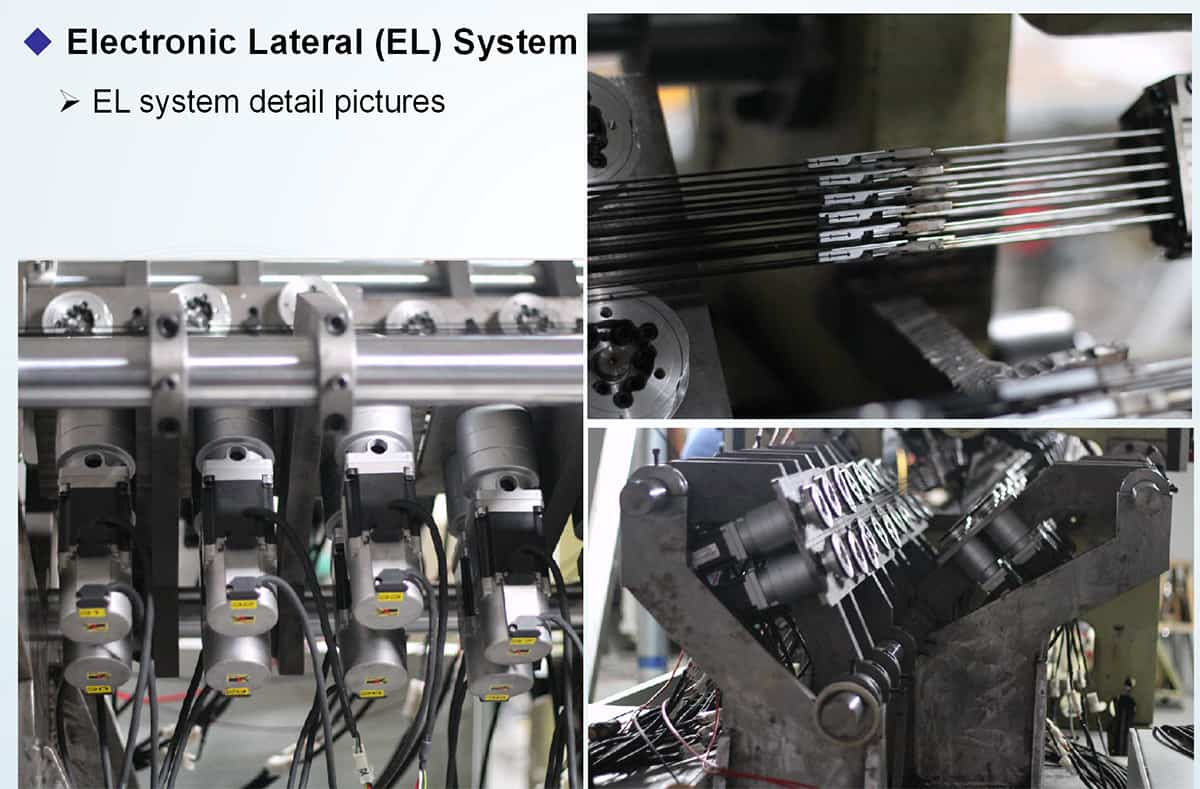

- PRODUCT DETAILS

- TECHNICAL DRAWINGS

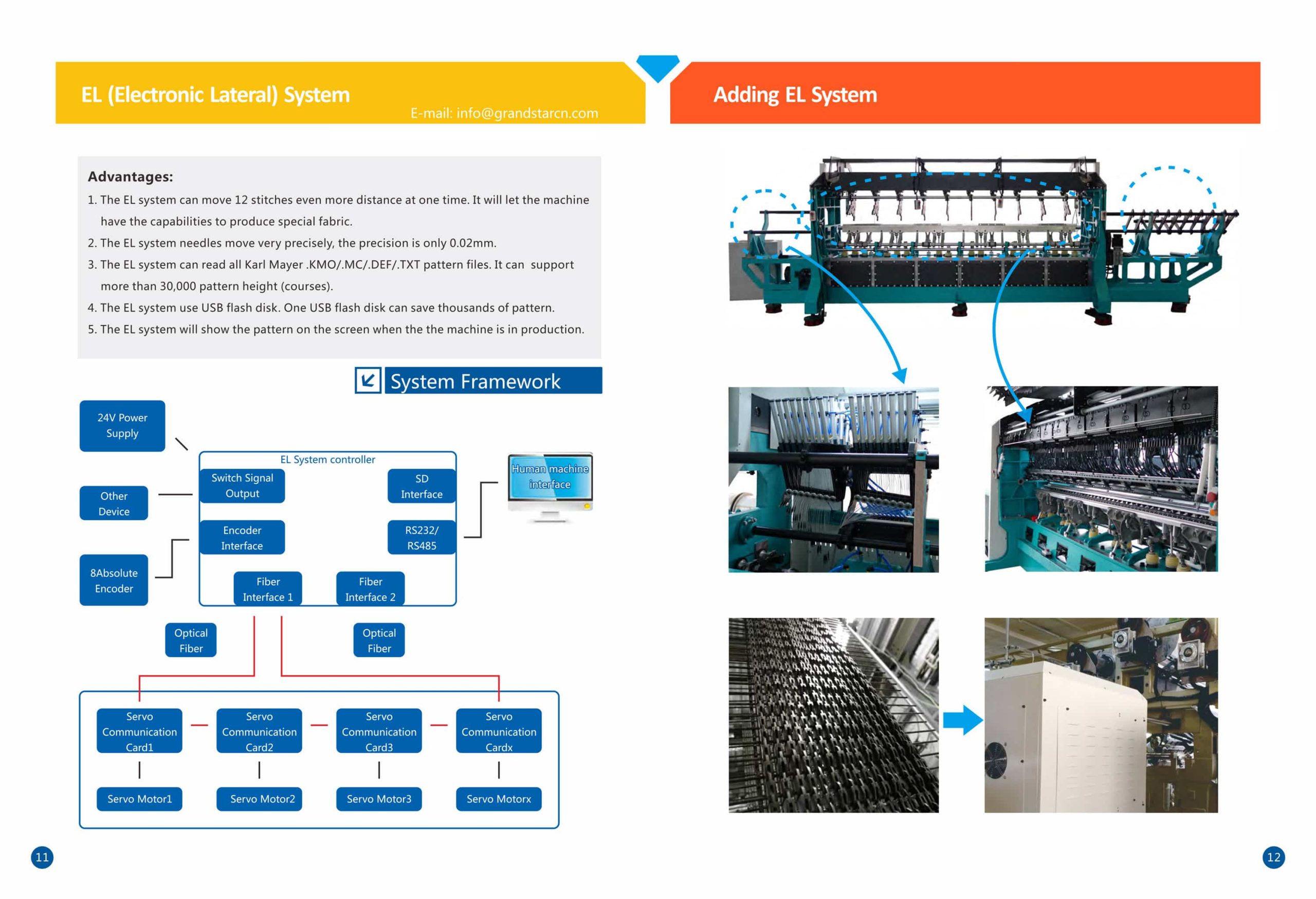

1. Expanded Movement Range

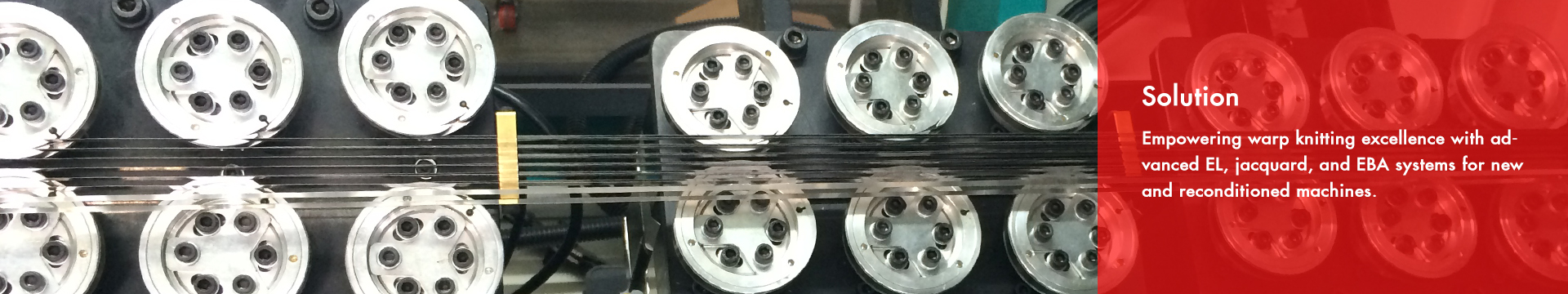

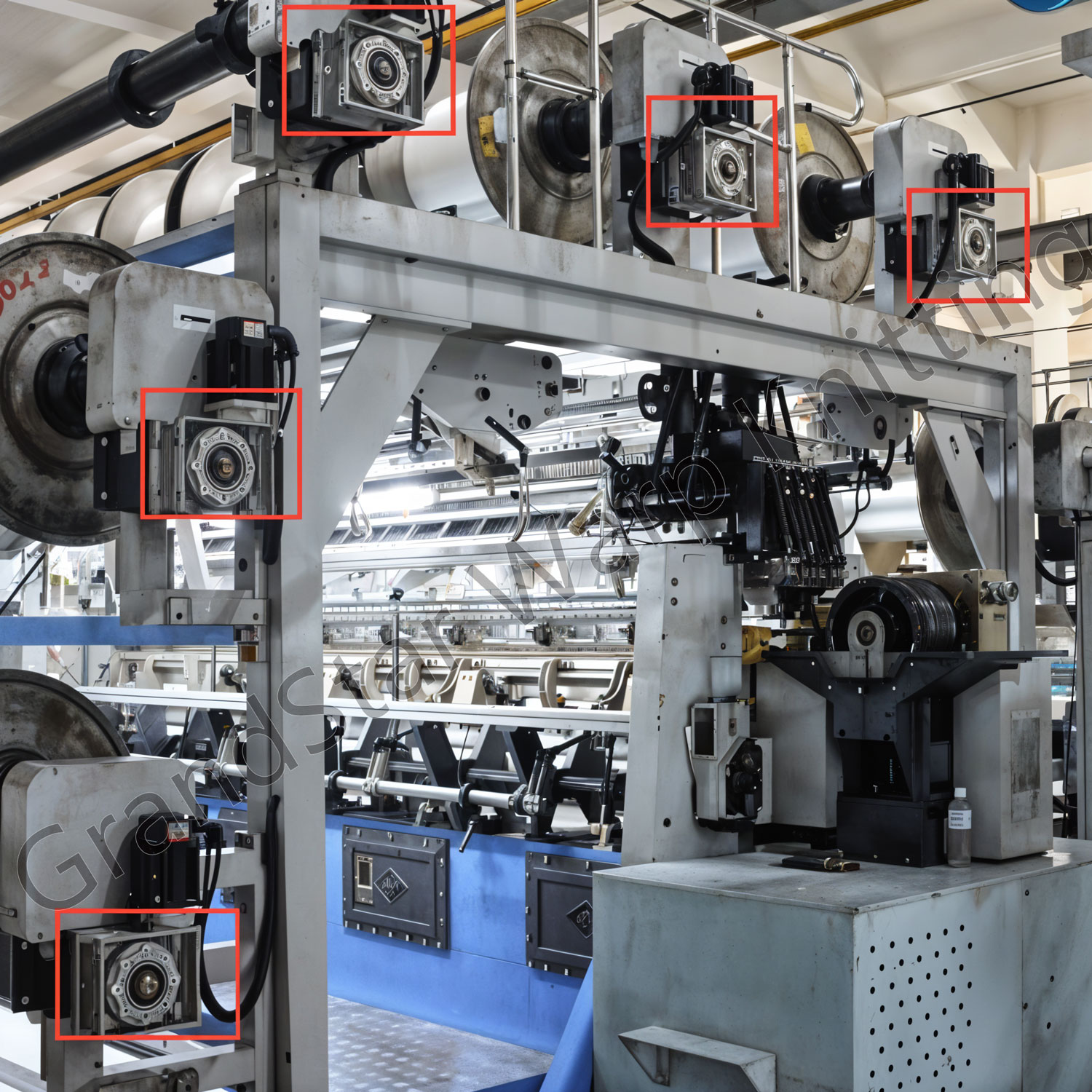

The EL System offers an exceptional moving distance of 60mm, extendable up to 80mm, allowing manufacturers to execute advanced and intricate fabric processes on both Tricot and Raschel machines. This feature paves the way for exploring new possibilities in fabric design and production.

2. Unmatched Precision

Designed for ultimate accuracy, the EL System ensures needle movements with a precision exceeding 0.02mm. This level of precision guarantees consistent, flawless results, meeting the stringent quality demands of modern textile production.

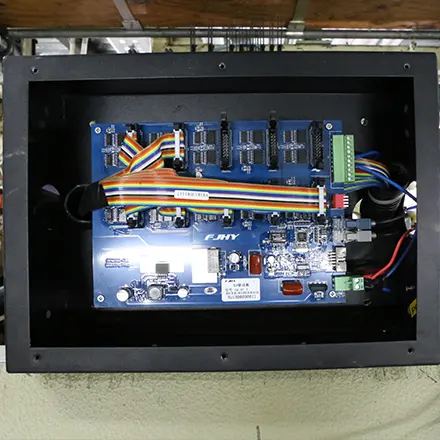

3. Comprehensive File Compatibility

The EL System supports an extensive range of file formats, including .KMO, .MC, .DEF, .TXT, .BMP, .SZC, and more. It can handle single process files with over 80,000 lines, making it a versatile and powerful solution for processing even the most complex fabric patterns.

4. Advanced Storage Capabilities

Equipped with USB storage technology, the system accommodates thousands of patterns on a single USB flash drive. This simplified storage, transfer, and retrieval process boosts operational efficiency and ensures smooth data management.

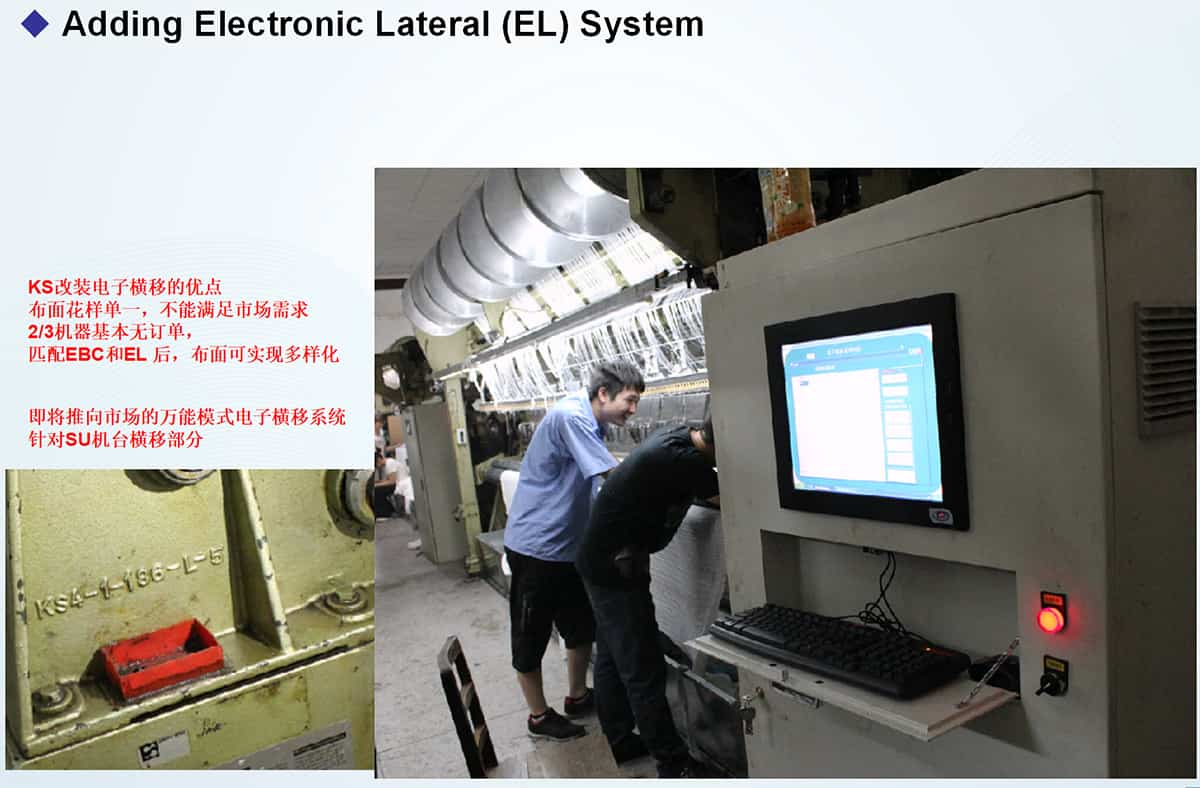

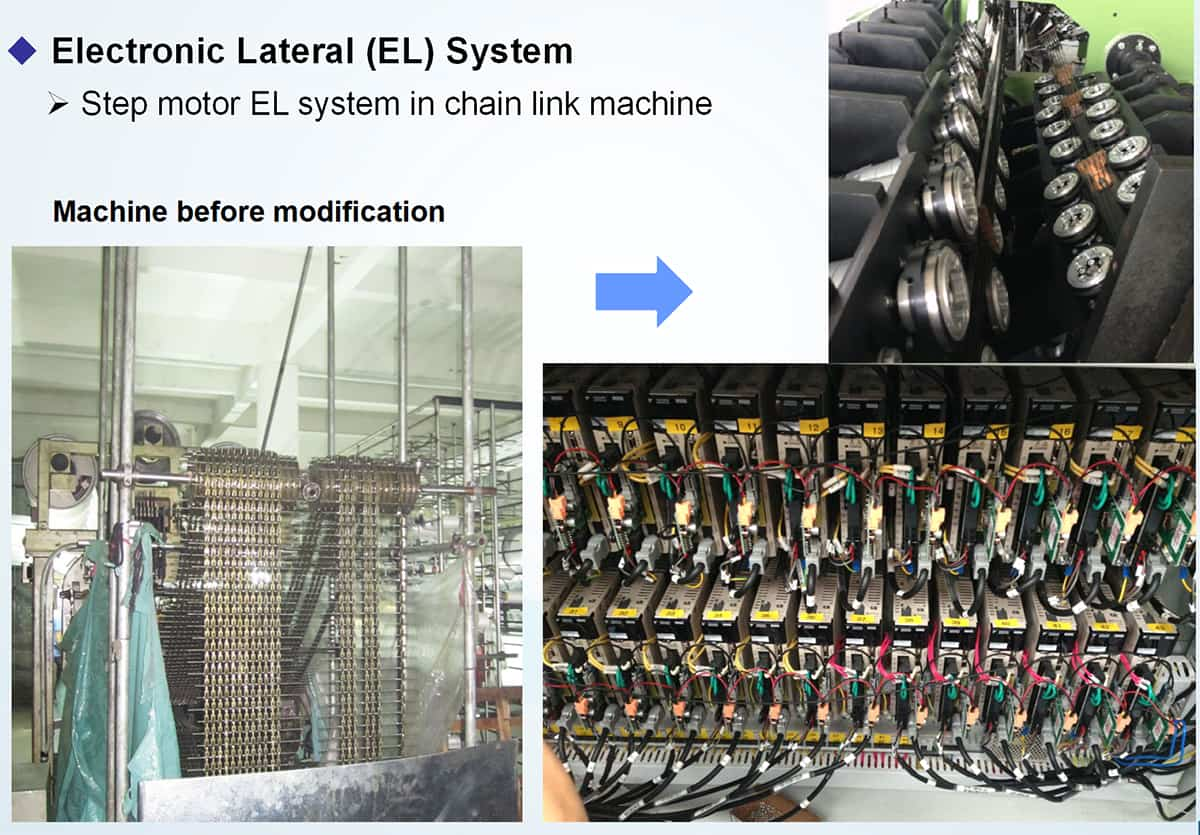

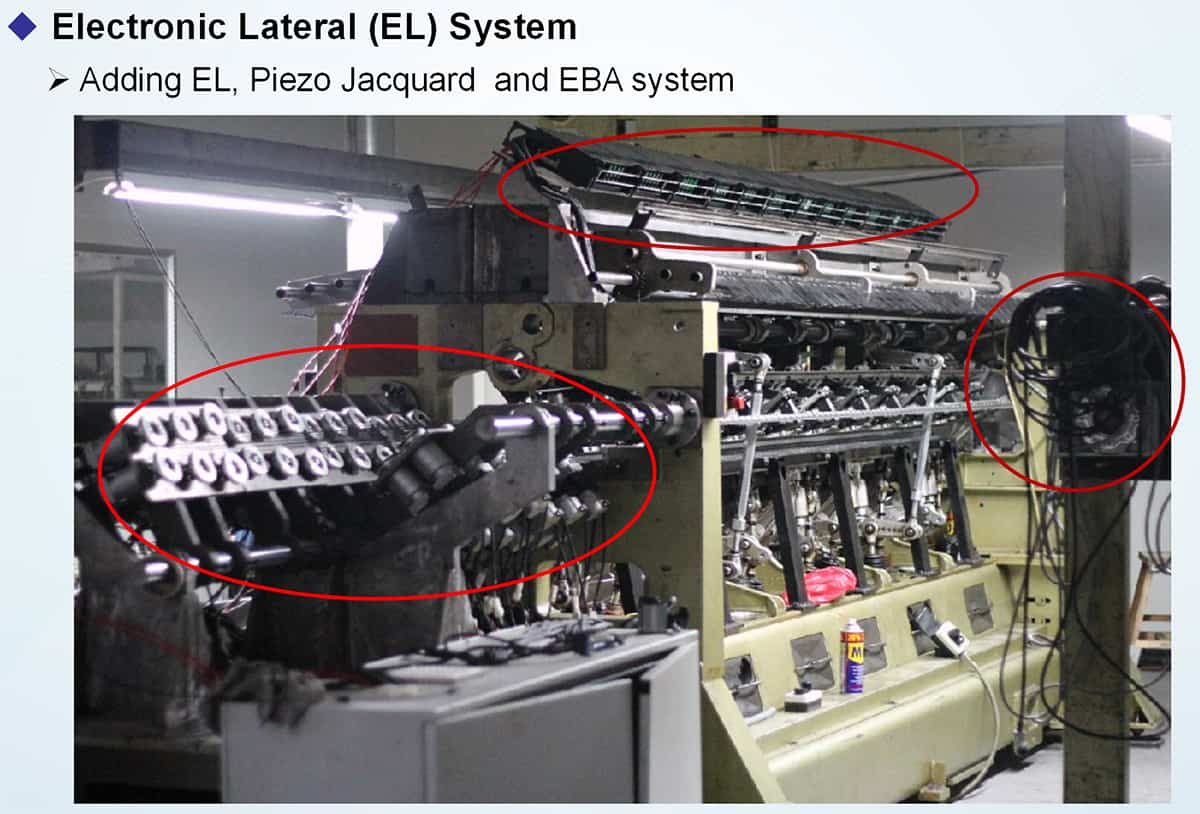

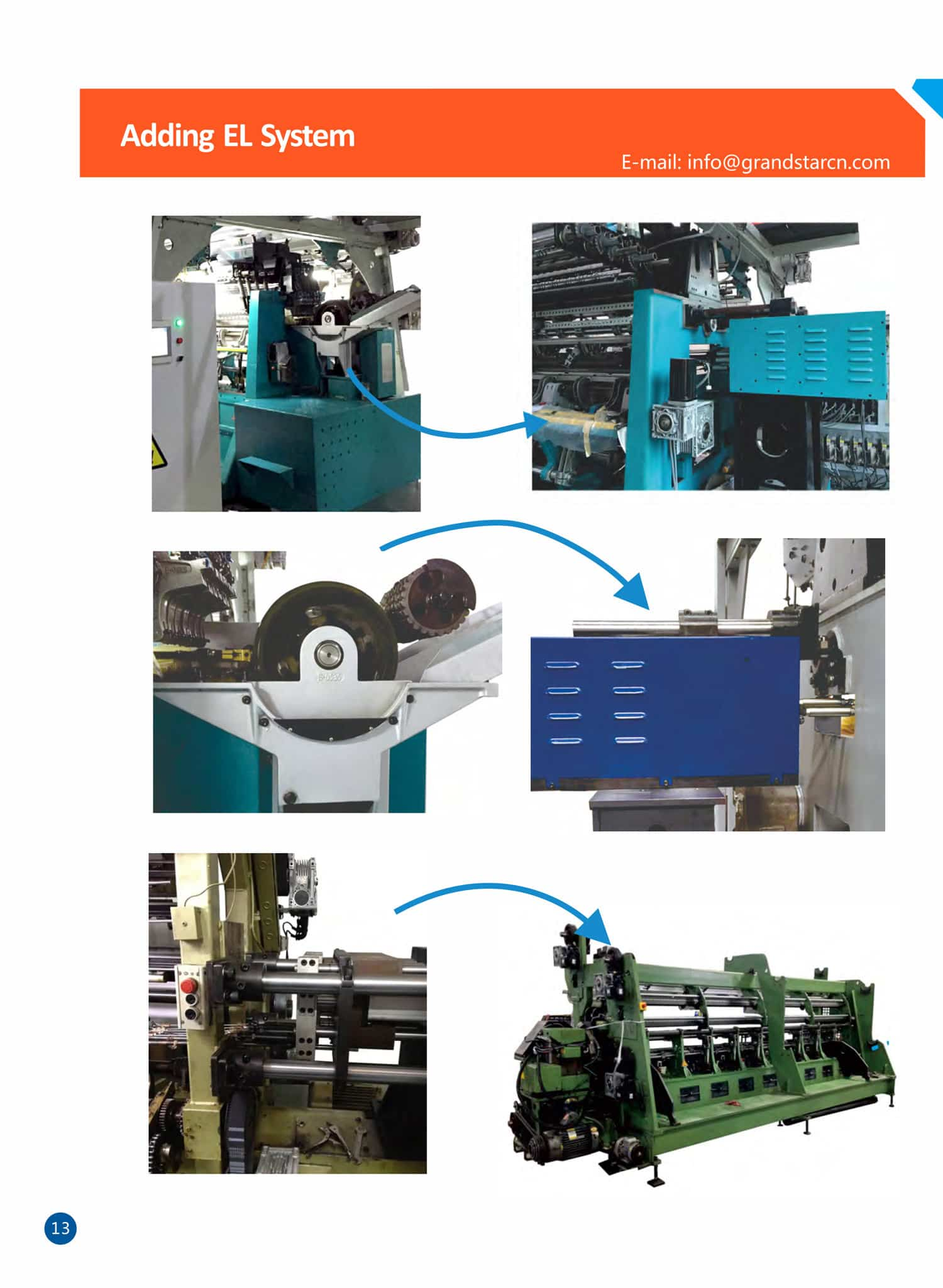

5. Seamless Machine Upgrades

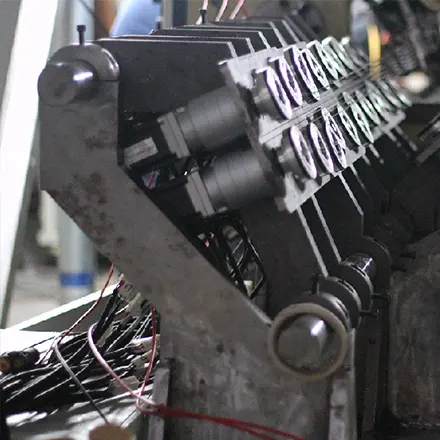

The EL System is designed to modernize legacy warp knitting machines by replacing outdated pattern disks with advanced electronic controls. This upgrade significantly enhances machine functionality, extends the lifespan of older equipment, and reduces the need for costly replacements.

Application

- Innovative Fabric Designs

Enables the production of intricate and complex patterns on Tricot and Raschel machines, catering to high-fashion and technical textiles. - Upgrading Legacy Machines

Modernizes older warp knitting machines, transforming them into high-performance systems capable of meeting contemporary textile demands. - High-Precision Textile Manufacturing

Ensures exceptional accuracy for creating flawless fabrics in industries such as fashion, automotive, medical textiles, and home furnishings. - Versatile Pattern Processing

Supports extensive pattern files, making it ideal for manufacturers producing unique and customized fabric designs. - Efficient Data Management

Simplifies pattern storage and transfer, enabling seamless operations for both large-scale and small-scale textile producers.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |