Fall Plate Raschel Lace Machine 76-Bars

| Fall plate Multibar Raschel Lace Machine – Warp Knitting Machine | |

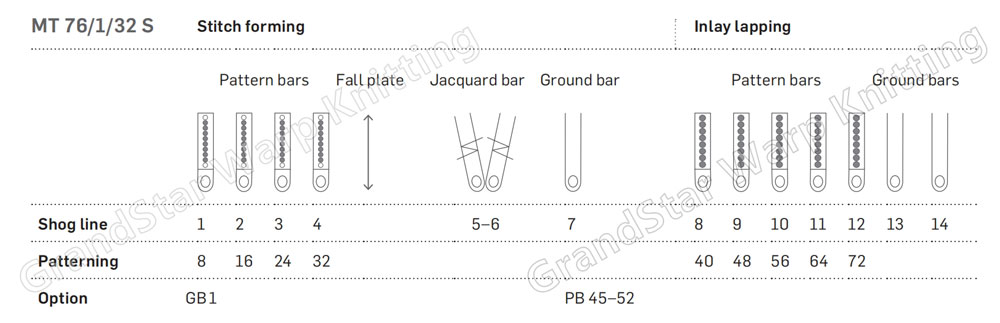

| Model No. | GS-MT 76/1/32 |

| Pattern Bars | 72 Bars |

| Ground Bars | 3 Bars |

| Jacquard Bars | 1 Bar |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

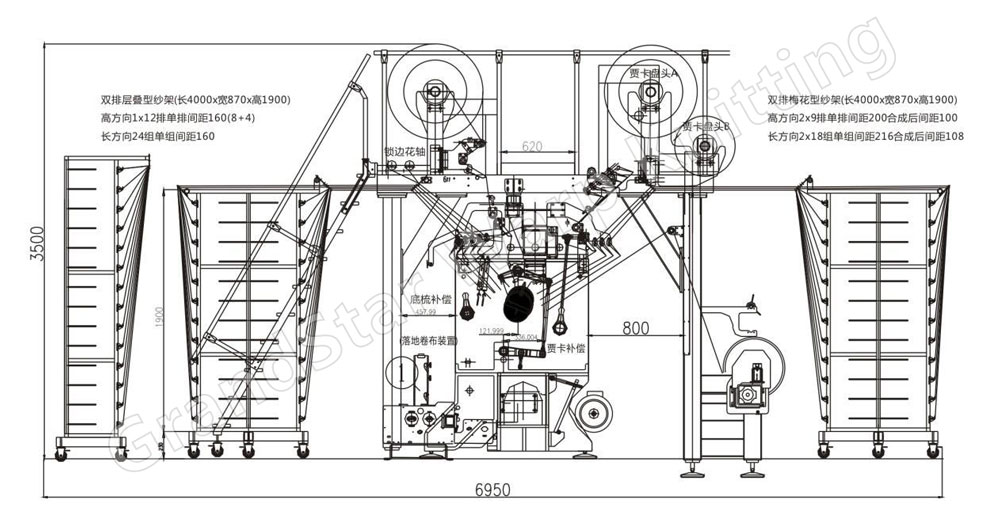

- TECHNICAL DRAWINGS

- CUSTOMER TESTIMONIALS

New Fall Plate Multibar Jacquard Lace Raschel Machine

Engineered for Premium Elastic and Rigid Lace Production

Key Features

- Split Jacquard Bars: Equipped with two split Jacquard bars and one guide bar, ensuring precise and consistent stitch formation.

- Advanced Rear Guide Bars: Features two rear guide bars capable of counter-lapping, offering exceptional pattern versatility for intricate designs.

- Flexible PB2-11 System: Easily replaceable with GB1, providing enhanced operational flexibility and adaptability for various production requirements.

- Super Multi-Functional Design: Built to meet diverse manufacturing needs, allowing for seamless production of both elastic and rigid lace.

- Innovative Fabric Capabilities: Produces ultra-light, transparent, and highly durable ground fabrics, setting a new benchmark in warp knitting technology.

Technical Specifications

- Working Width:

- 3403 mm (134 inches)

- 5334 mm (210 inches)

- Gauge Options:

- E24

- E28

GrandStar® Command System

A state-of-the-art operator interface designed to configure, control, and adjust the machine’s electronic functionalities for maximum precision and ease of use.

Integrated Monitoring Systems

- LaserStop: Ensures accurate and consistent monitoring during operations.

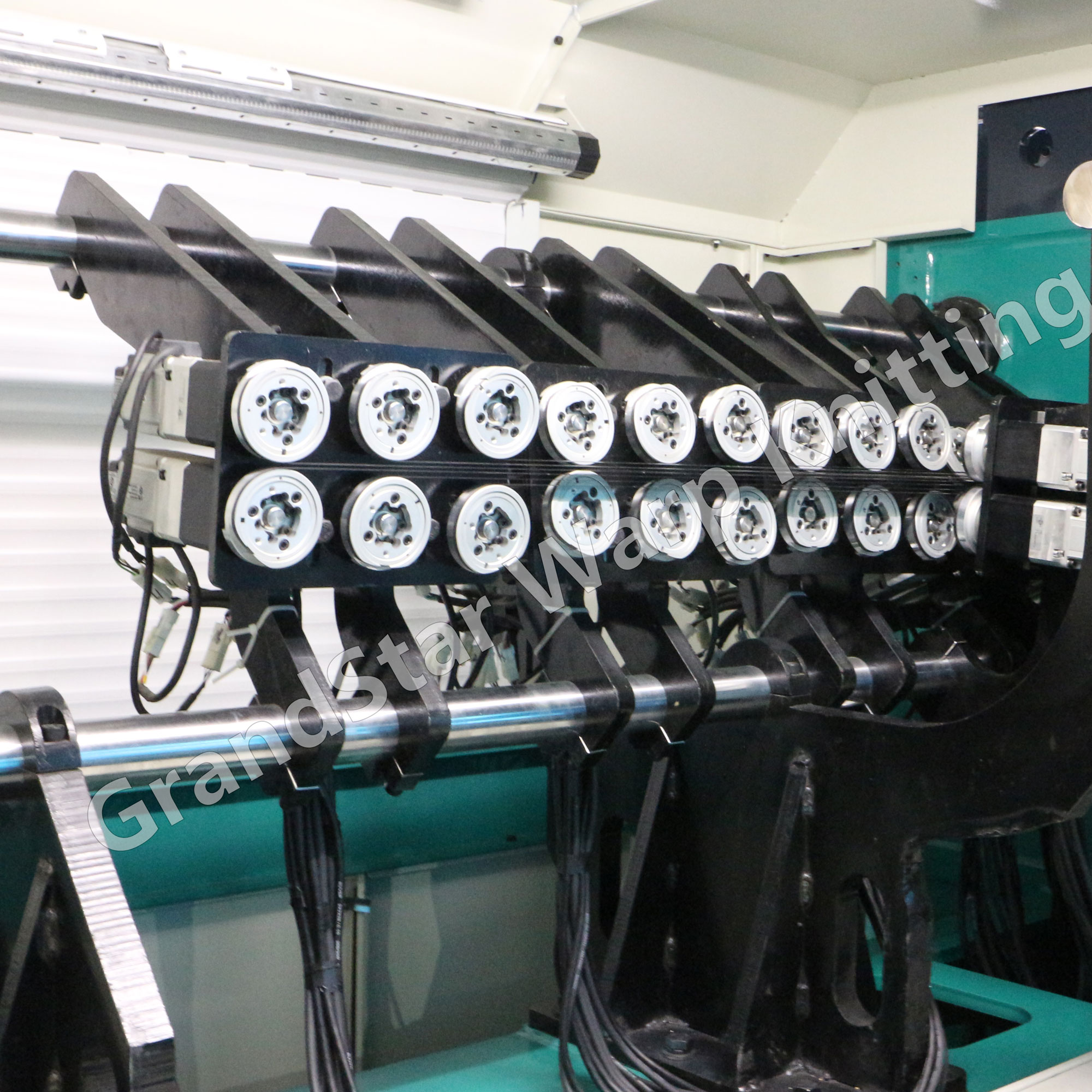

Yarn Let-Off Device

- Four electronically controlled yarn let-off gears dedicated to the ground guide bars and Jacquard bars, enabling superior tension control and flawless knitting performance.

Fabric Take-Up System

- Electronically regulated fabric take-up driven by a geared motor, comprising a system of four rollers for smooth, efficient fabric handling.

Batching Device

- A separate floor-standing cloth rolling device for optimal fabric collection and storage.

Pattern Device EL

- Electronic guide bar control for both ground and pattern guide bars, including string bars, enabling unparalleled design flexibility.

Electrical Equipment

- Drive System: Speed-regulated drive for precise control.

- Power Requirements:

- Total connected load: 25 kVA

- Voltage: 380V ± 10% (Three-phase power supply)

- Main power cord: Minimum 4mm² (three-phase four-core power cord)

- Ground wire: Minimum 6mm²

- Integrated Heat Management: Oil/water heat exchanger for efficient temperature control.

Operating Conditions

- Temperature: 25℃ ± 3℃

- Humidity: 65% ± 10%

- Floor Pressure: 2000–4000 KG/㎡

Training & Service

Installation & Training

Our warp knitting machine services include training via manuals, videos, online guidance, and on-site sessions, supported by local teams in five countries and over 20 global training programs.

Local Service

Grandstar provides on-site support for optimal machine performance in Turkey, India, Vietnam, Indonesia, and the USA, along with proactive care through routine inspections and expert maintenance.

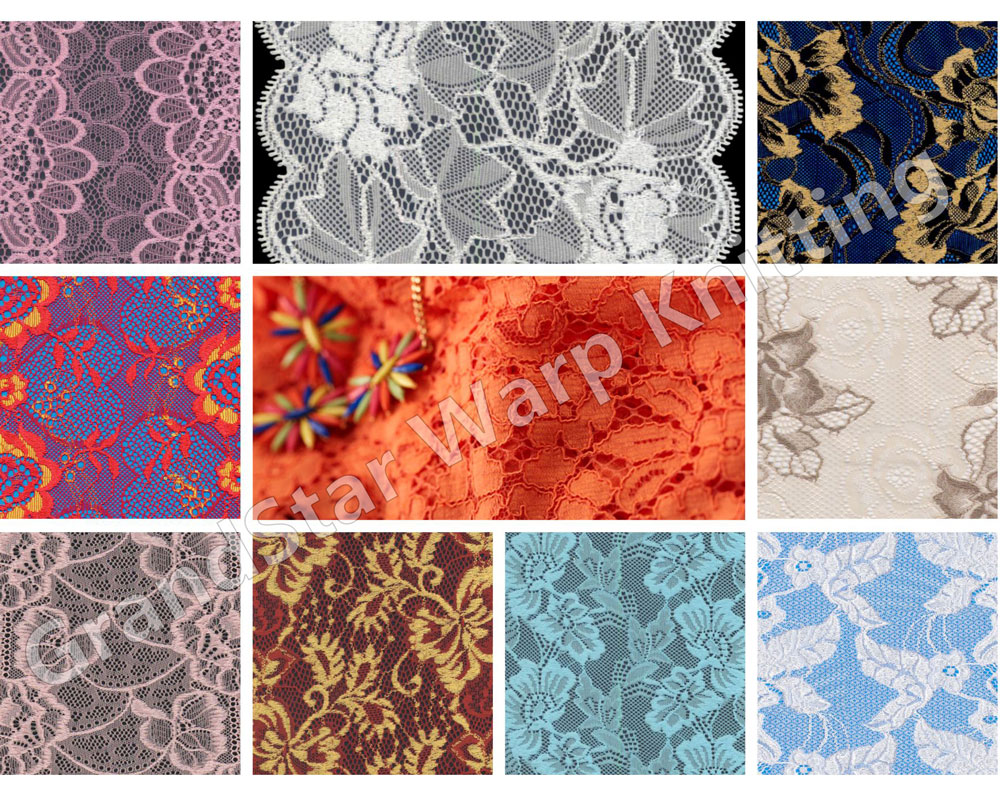

Application

Applications of Fall Plate Raschel Lace Machine

Here are the key applications:

-

High-Fashion Apparel:

Designers use lace produced by Fall Plate Raschel machines in creating luxurious dresses, gowns, and evening wear. The machine’s ability to generate complex patterns makes it indispensable for haute couture. -

Home Décor:

Lace fabrics produced by these machines are often used in creating elegant curtains, tablecloths, and cushion covers. Their intricate designs enhance the aesthetics of interior spaces. -

Intimate Wear:

Fall Plate Raschel machines are widely used to manufacture lingerie and other intimate apparel. The delicate and detailed patterns produced by the machines cater to this segment’s demand for elegance and comfort. -

Curtains and Upholstery:

In the home furnishing industry, Fall Plate Raschel lace machines produce fabrics that combine durability with decorative appeal. These fabrics are used for upholstery, window treatments, and other decorative applications.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |

-

Philip Im

★★★★★Post a review on Aug 21, 2015 From Mexixo

Operating the Multibar Fall Plate Lace Machine by GrandStar in a knitting factory is a seamless and efficient experience, thanks to its innovative design and advanced functionality. Known for its precise engineering, the machine ensures high-quality lace production while maintaining impressive ease of use for operators. It excels in efficiency, significantly boosting production rates without compromising the intricate patterns characteristic of lace fabrics. The machine’s stable quality is particularly noteworthy—its reliable performance minimizes downtime, reduces maintenance requirements, and guarantees consistent output, even under intensive production schedules. By delivering robust and uniform results, the Multibar Fall Plate Lace Machine has become a cornerstone in knitting factories, empowering manufacturers to meet demanding production goals with confidence.

-

Salvatore marrapesa

★★★★★Post a review on Jan 1, 2016 From Indonesia

The Multibar Fall Plate Lace Machine by GrandStar transforms knitting factory operations with its remarkable efficiency and precision. Designed to handle intricate lace patterns seamlessly, this machine ensures consistent quality in every piece produced. Operators find it user-friendly, with intuitive controls that minimize downtime and boost productivity. Its advanced fall plate mechanism delivers exceptional detail and texture, making it a favorite for high-demand lace production. Beyond performance, GrandStar’s commitment to excellent service stands out; their responsive support team and reliable maintenance services ensure the machine operates at peak performance, reinforcing their reputation as a trusted industry leader.