Geogrid Warp Knitting Machine for Reinforced Mesh and Grid Fabric

Why Is the Demand for Stronger Mesh and Grid Fabrics on the Rise?

As cities expand at a rapid pace, the need for stronger, more reliable ground reinforcement solutions is becoming increasingly urgent. Builders and engineers are turning to geogrids – high-strength mesh fabrics placed beneath roads, behind retaining walls, and within soil layers – to stabilize and support infrastructure.

To meet growing construction demands, manufacturers need to produce these geogrids faster, better, and more efficiently. That’s where the Geogrid Warp Knitting Machine comes in. Designed to create durable, high-performance mesh fabrics, this machine streamlines production while ensuring quality and consistency. It not only increases output but also reduces downtime and operating costs.

In today’s fast-paced world, companies are searching for machines that deliver both speed and reliability. A well-designed geogrid warp knitting machine meets these expectations with ease. As infrastructure needs rise around the globe, one question echoes across industries:

Could this machine be the foundation of safer, stronger cities?

Let’s take a closer look.

Understanding the Geogrid Warp Knitting Machine

What This Machine Is Made For

The Geogrid warp knitting machine is built to make strong mesh. It is made to create geogrid fabric that can hold a lot of force. The fabric does not tear easily. People use it in roads, walls, and ground support. Builders need this kind of fabric for safety. This machine helps them get it fast and with good quality.

Why This Machine Works Well

The Geogrid warp knitting machine gives the right mix of speed and power. It makes the same strong pattern again and again. It also keeps working for a long time. It is strong and made for big jobs. Many factories need this kind of machine to meet daily work.

Where You Can Use the Fabrics

The fabrics from this machine are very useful. They are perfect for big building jobs. Workers use them to make the ground steady. They also use them to stop soil from moving. That is why the Geogrid warp knitting machine is so important.

Technology Behind the Strength

How the Machine Stays Strong

The Geogrid warp knitting machine keeps the threads tight and even. This makes sure the fabric is strong. Every part of the mesh stays in place. This helps stop breaks and holes. It works the same way every time.

What You Can Change on the Machine

You can change many things on this machine. You can make the fabric thick or thin. You can also make the holes in the mesh big or small. This helps users make the fabric they really need. That way, it fits many kinds of jobs.

What Kind of Thread It Uses

The machine works with many thread types. It is great for HDPE and polyester. It also works with yarns used in strong building fabrics. These threads help the mesh last long in tough weather. The Geogrid warp knitting machine makes sure they all work well.

Meet Grand Star Technology: A Global Leader in Knitting Solutions

Who We Are

Grand Star Technology makes warp knitting machines. We started in 2012. Since then, we have helped many clients. We work in the United States, Japan, Turkey, and more. We focus on smart machines that do more in less time. They help build a strong base for the textile world.

Why People Trust Us

People like our strong machine parts. The company listens to customer needs. They help before, during, and after the sale. We fix problems fast. Our team gives support when people need help. We care about doing the job right.

What We Want to Do Next

The company always works to get better. We bring new ideas into the machines. We want to help the textile world grow. We work with care, honesty, and smart thinking. Grand Star is not only a machine maker. We lead the way for future machines in the textile field.

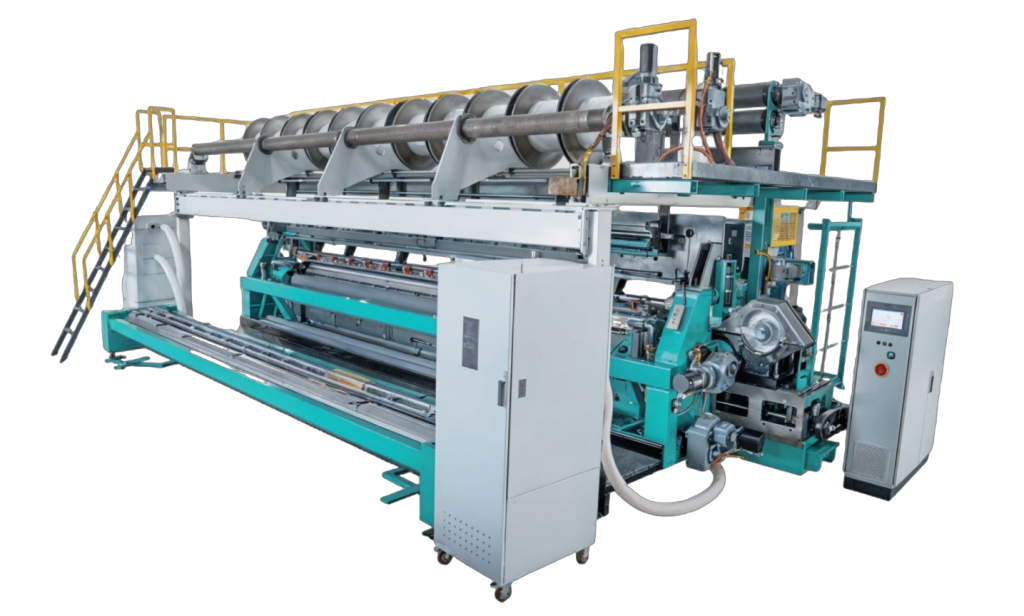

Introducing the Star Product: Double Needle Bar Raschel for Net

Made to Build Strong and Even Mesh

The Double Needle Bar Raschel for Net is made to create strong and even geogrid mesh. It helps make fabric that is used in roads, walls, and soil support. This machine is built for power and steady performance. It comes in many working widths. You can choose from 130″, 180″, 210″, or 256″. The gauge options are also many. You can pick E2, E3, E6, E9, E12, or E18. The warp beam support can hold 4, 6, 8, or 9 beams. Each beam can be 32 inches wide. This setup helps meet many needs in big projects.

Built for Speed and Easy Use

The Double Needle Bar Raschel for Net runs fast. It also keeps the thread tight. It does not need much manual work. The machine has a smart control system called GrandStar® COMMAND SYSTEM. The screen is simple to use. The operator can set up, control, and adjust everything easily. There is also a yarn let-off device. Each beam has its own drive. This helps keep the yarn smooth. The fabric take-up system works with a motor and four rollers. This helps pull the fabric without damage. The machine works well and saves time.

Good for Many Materials and Jobs

This machine is very flexible. It can work with many yarn types. You can use HDPE, polyester, or other strong fibers. These materials are good for building and support uses. The Geogrid warp knitting machine helps make mesh for many different jobs. Some use it for roads. Others use it for soil walls. Many companies like it because they can use one machine for many tasks.

Why Choose Grand Star’s Warp Knitting Solution?

Works Well in Big Factories

The machines from Grand Star work in tough places. Many factories use them for long hours. They keep working without breaking down. This makes them good for large projects. The Geogrid warp knitting machine is strong and steady. It gives the same result every time. That is why many builders trust it.

Support and Training Around the World

Grand Star gives help before and after you buy. We teach people how to use the machines. You can learn from videos, books, or online. You can also get help at your site. Teams in Turkey, India, Vietnam, Indonesia, and the USA are ready to guide you. We know how to solve problems fast. This makes work easy for users.

Used by Many Big Companies

Many groups trust Grand Star. Civil engineers use it for roads and walls. Textile makers use it for special fabrics. People in geotechnical fields also use it. They choose it because it works well and lasts long. The Geogrid warp knitting machine has become a top choice in many countries.

Join the Movement Toward Cleaner, Stronger, Smarter Manufacturing

Grand Star keeps finding new ways to improve their machines. The company adds smart parts to help users. The goal is to make work easy and smooth. The Geogrid warp knitting machine is always getting better. It helps build a strong future for geogrid production. The machines are made to waste less. They use less power. They make more fabric in less time. This means users get more work done and save energy. The Geogrid warp knitting machine is a good step toward cleaner and faster production.

Grand Star is not just building machines. We are building the future. Our work helps people build stronger cities. Many companies follow our path. The Geogrid warp knitting machine shows how smart design can change the world.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.