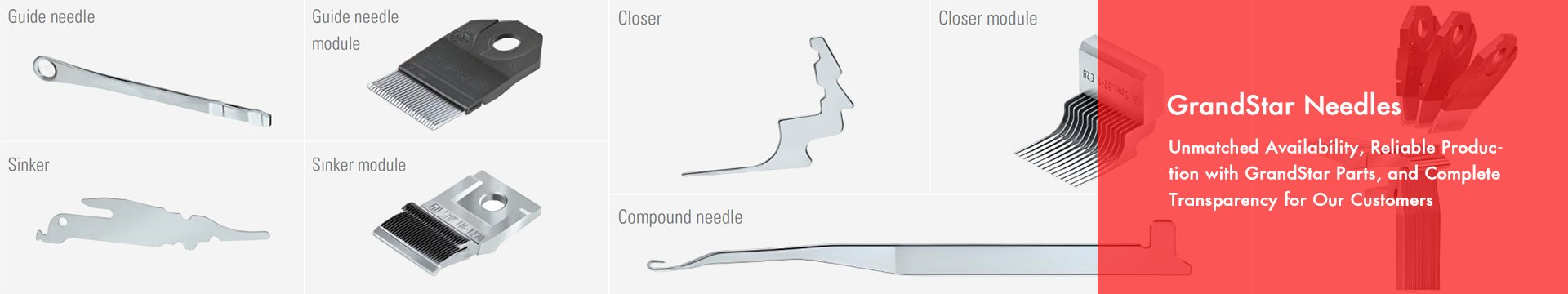

Guide Needle

| Guide Needle (Module) For Warp Knitting Machine | |

| Model No. | L-XX-XX |

| Place of Origin | Fujian, China |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- PRODUCT LIST

Guide Needles (Modules): Precision and Durability in Warp Knitting

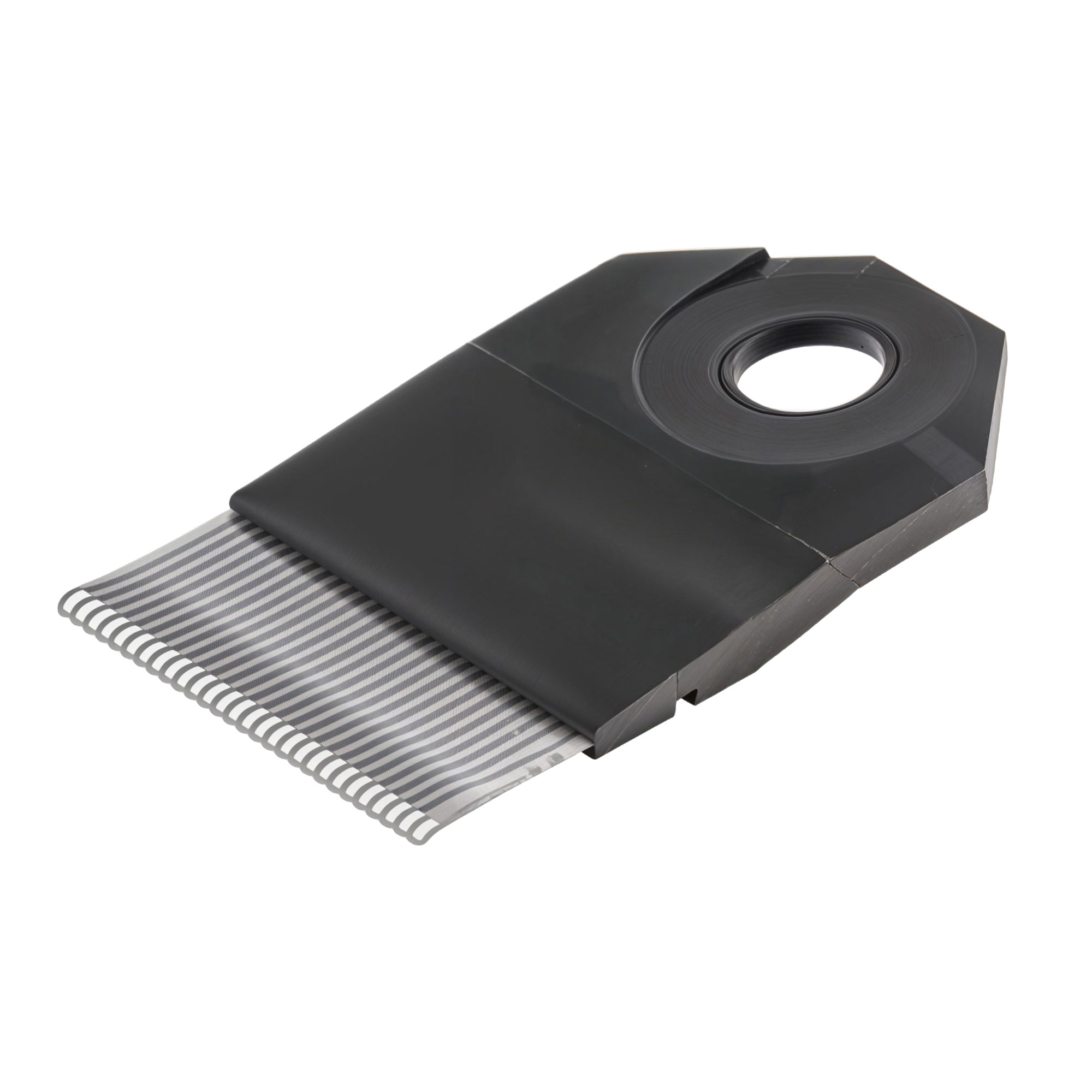

Guide needles, commonly referred to as “eye needles,” are indispensable components in the warp knitting industry, ensuring smooth and precise operation of warp knitting machines. These modules are meticulously designed to guide warp yarns through the knitting process, playing a pivotal role in the formation of fabric loops.

The Role of Guide Needles in Warp Knitting Machines

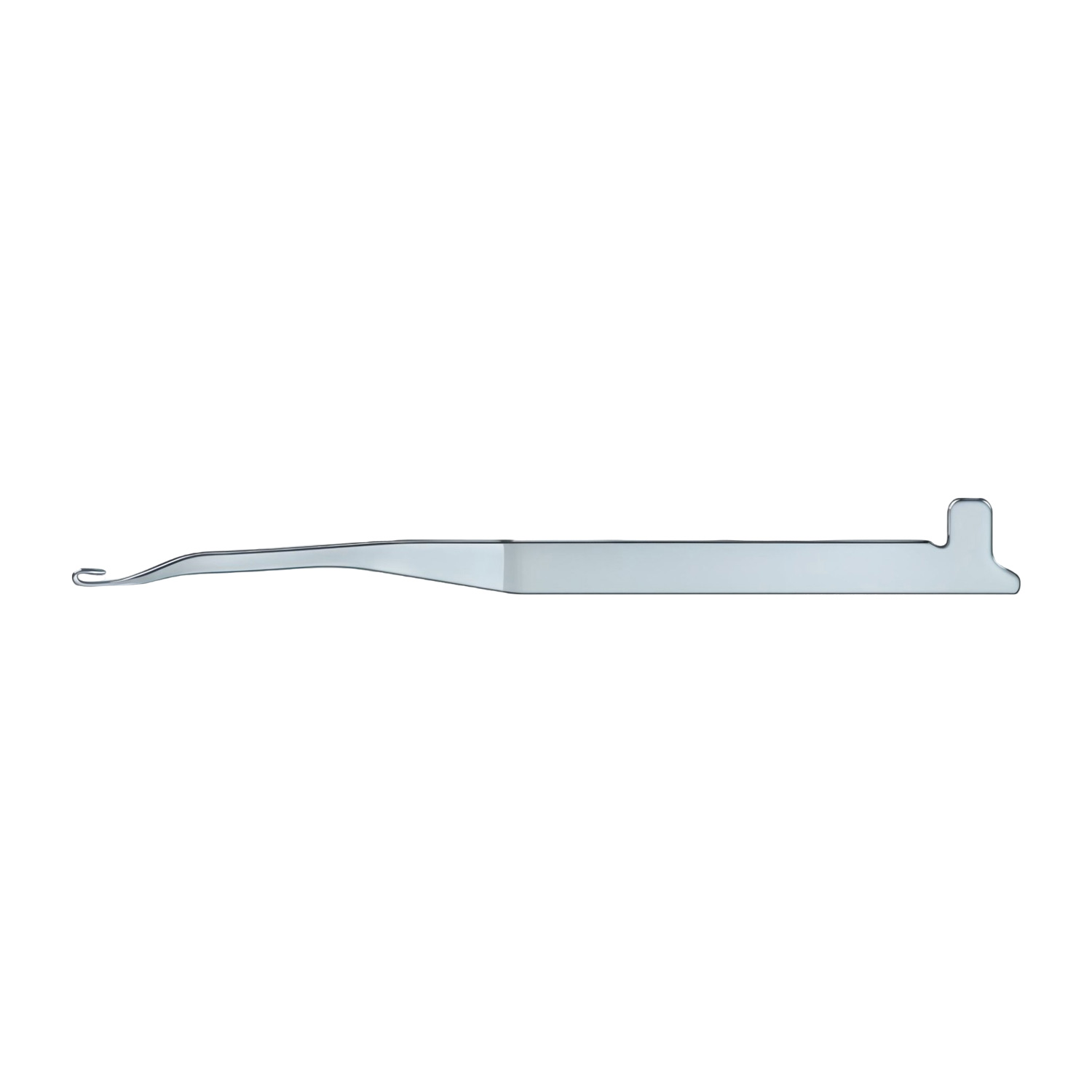

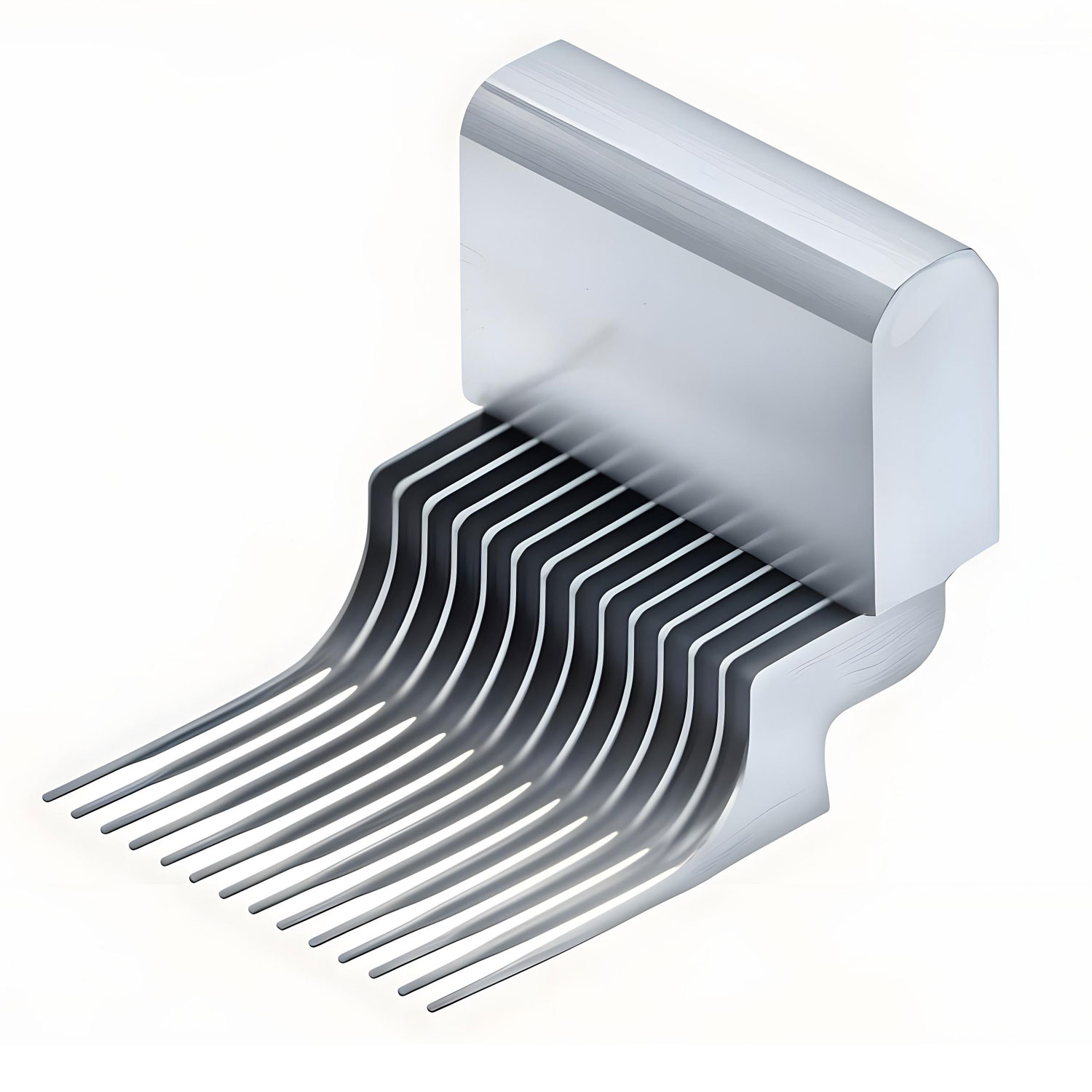

As a core looping element of warp knitting machines, guide needles are composed of thin steel sheets featuring a guide hole. This hole facilitates the passage of warp yarn, directing it around the knitting needle and ensuring its accurate placement for the fabric formation process. To simplify installation and ensure seamless operation, multiple guide needles are integrated into modules, commonly referred to as “seats,” with fixed spacing that aligns with the machine’s specifications. These seats are then assembled into comb-like structures, enabling efficient handling and installation.

Key Factors Influencing Guide Needle Performance

The performance and longevity of guide needles depend on several critical factors:

- Number of Guide Bars: Machines with multiple guide bars require guide needles capable of accommodating complex yarn movements.

- Yarn Specifications: The diameter and type of yarn being processed determine the size of the guide needle’s holes, ensuring optimal fit and functionality.

- Yarn Tension and Thread Passage: High yarn tension or excessive thread friction can contribute to increased wear and tear, impacting the lifespan of guide needles.

Modern Guide Needle Modules: Advanced Materials and Engineering

To address the challenges of wear and improve durability, modern guide needle modules are manufactured using advanced injection molding techniques and high-performance plastics. These materials offer exceptional dimensional stability while remaining lightweight, a crucial attribute for maintaining machine efficiency and reducing operational strain.

Choosing the Right Guide Needles for Your Warp Knitting Machine

Different warp knitting machines require guide needles tailored to their specific operational needs. Factors such as machine type, knitting density, and yarn properties must be considered when selecting guide needles to ensure optimal performance and fabric quality.

Why Guide Needles Matter

Guide needles are not merely components but are vital contributors to the precision and efficiency of warp knitting machines. Their design and material composition directly impact the quality of the final fabric, making them a critical choice for manufacturers aiming to produce superior warp-knitted textiles.

By integrating high-performance guide needle modules into your warp knitting machines, you ensure enhanced productivity, reduced maintenance, and exceptional fabric quality, establishing your position as a leader in the textile industry.