Multibar Lace Weaving Machine 52 Bars

| Jacquard Multibar Lace Machine – Raschel Warp Knitting Machine | |

| Model No. | GS-JL 52/1 |

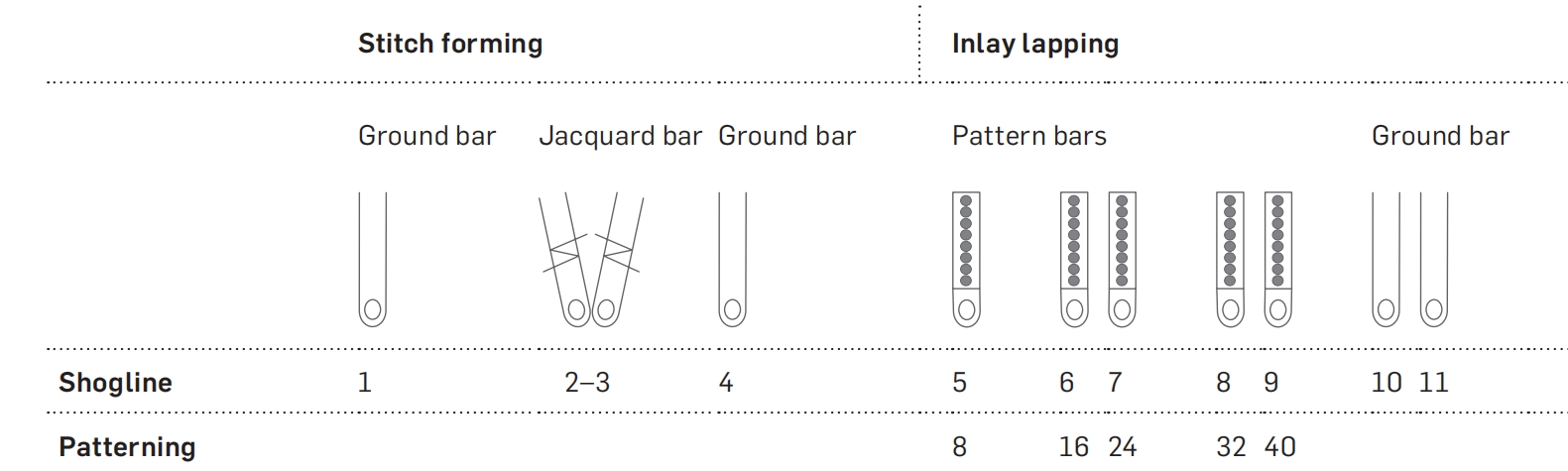

| Pattern Bars | 40 Bars |

| Ground Bars | 4 Bars |

| Jacquard Bars | 1 Bar (split threading for counter-lapping) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

- TECHNICAL DRAWINGS

Working Width and Gauge

Available Working Widths:

- 3403 mm (134 inches)

- 5334 mm (210 inches)

Gauge Options:

- E18

- E24

- E28

GrandStar® Command System

An operator interface for the refined, systematic setting, accommodating, and calibrating of all electronic features on the device for efficiency and reliability.

Integrated Monitoring Systems

- LaserStop System: Facilitates proper fault determination and smooth running of machines.

Yarn Let-Off Device

- Four electronically controlled yarn let-off gears for ground guide bars and Jacquard bars to control the yarn tension and the quality of the stitch.

- Fabric Take-Up System

- Automatic controlled take-up roll operated with geared motor along with four-roller for easy management of fabrics.

Electrical Equipment

- Drive System: Speed-regulated level in order to ensure fine and fuel-efficient control.

Power Requirements: - Total connected load: 25 kVA

- Voltage: Commercial: 380V ± 10% The circuit shall be a three phase power supply.

- Main power cord: Minimum of 4mm² (Three Phase Four Core).

- Ground wire: Minimum 6 mm².

Oil Supply

Oil water heat exchanger used to cool and regulate the temperature of the apparatus.

Equipment Working Conditions

- Temperature: 25℃ ± 3℃

- Humidity: 65% ± 10%

- Floor Pressure: 2000–4000 KG/㎡

Training & Service

Installation & Training

Our technical support covers warp knitting machine training via manuals, videos, online resources, and on-site programs in over 20 countries, with teams in five key regions.

Local Service

Grandstar supports machine efficiency with on-site services in Turkey, India, Vietnam, Indonesia, and the USA, plus routine inspections for continuous reliability.

Application

Fashion and Apparel

- The Jacquard Multibar Lace Machine is used predominantly in the manufacture of necessities of the fashion industry such as formal wears, wedding gowns, and other quality wears. It is used in the construction of complicated designs for the delicate lyras used in making undergarments, waist cinchers and ethnic wear clothing articles as they provide class and exclusivity to clothes.

Bridal Wear

- It’s an ideal machine for weaving delicate laces used in bridal garments such as wedding gowns, wedding veil and bridesmaids accessories such as gloves and scarves as depicted below. It is also used extensively in the creation of decorative laces that is in use in formal wears and occasion wears as well as ceremonial wear.

Home Décor and Textiles

- The machine produces decorative lace for curtains, upholstery, and table linens. These lace designs enhance interior aesthetics by adding a touch of elegance to home furnishings.

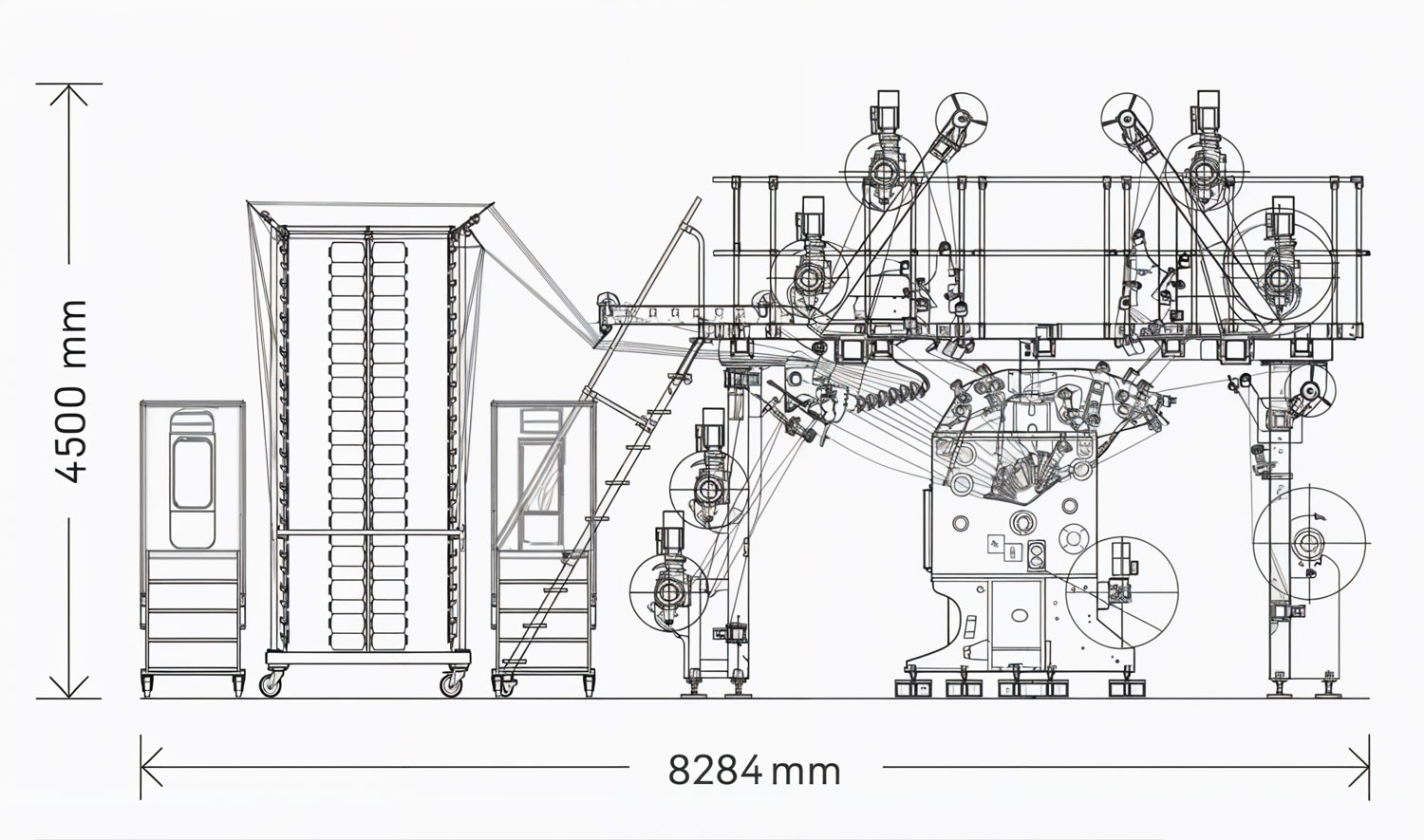

| Total Witdh | Total Depth | Total Height |

| 9478 mm | 8284 mm | 4500 mm |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |