Jacquard Raschel Fabric RSJC 4/2

| Raschel Jacquard RSJC 4/2 For Rigid Farics – Warp Knitting Machine | |

| Model No. | RSJC 4/2 (EL) |

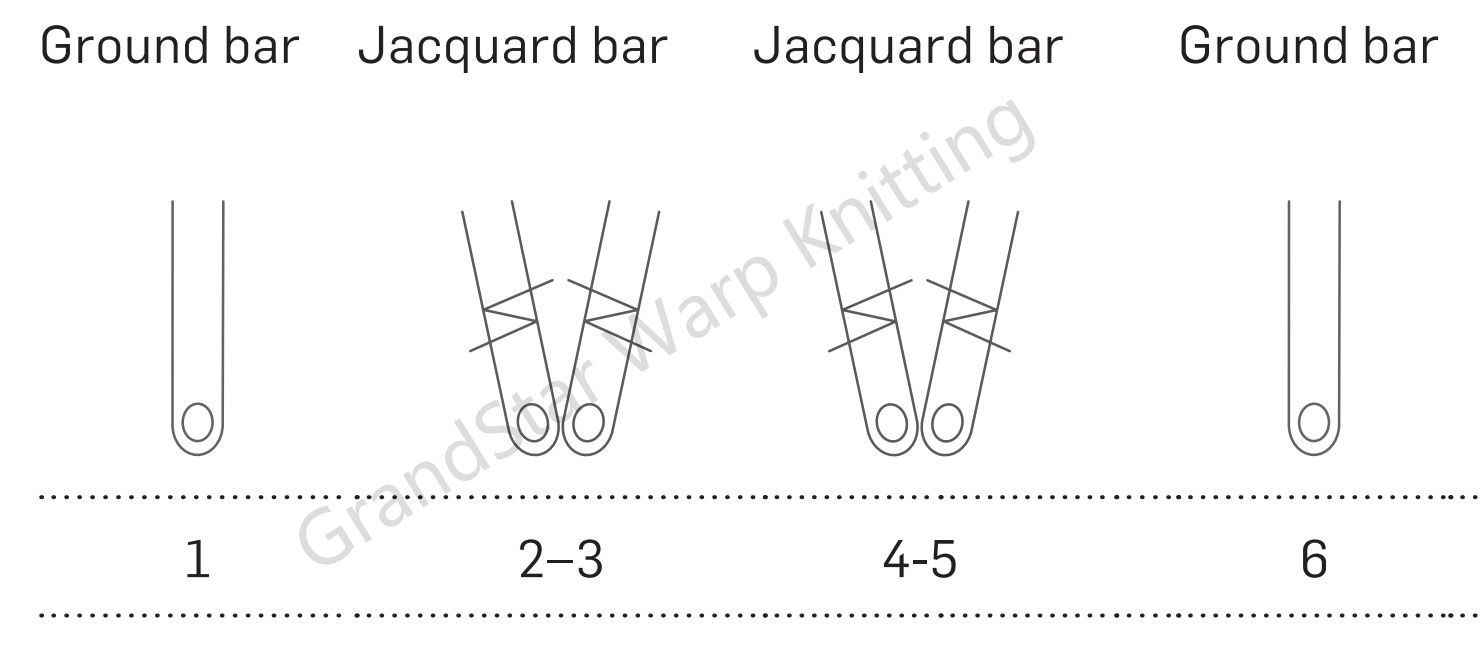

| Ground Bars | 2 Bars |

| Jacquard Bars | 2 Groups (4 Bars) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

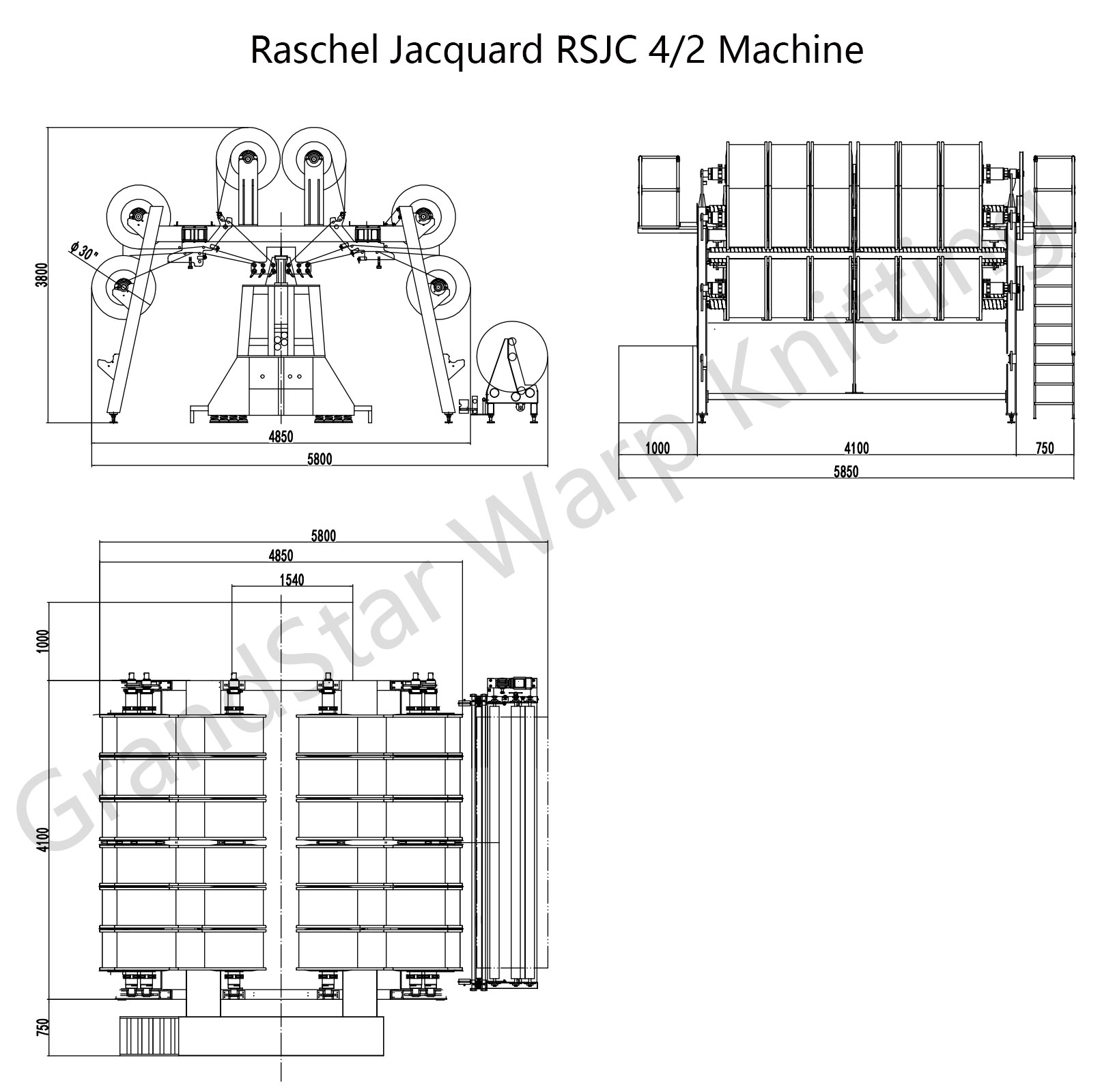

- TECHNICAL DRAWINGS

Working Width:

- 3454mm = 136 inch

- E24, E28

Bars / Knitting Elements:

- Separate needle bar and tongue bar

- Stitch comb bar

- Knockover comb bar

- 2 ground guide bars

- 2 group Jacquard bars, that is 4 Jacquard bars.

Warp Beam Support:

- Including six warp beam positions for sectional beams of 21 inch and 32 inch flange diameter

GrandStar® (GrandStar COMMAND SYSTEM):

- Operator interface to set up and control the electronic features of the typewriter style machine

Yarn Let-off Device:

- For each completely mounted warp beam position: One is the electronically controlled yarn let-off drive.

Fabric Take-up:

- Fabric take-up electronically controlled through geared motor with four rollers.

Batching Device:

- It also has a separate rolling device with maximum rolling diameter of 1270mm (50).

Pattern Drive:

Electronic guide bar drive EL, all guide bars shog up to 50 mm.

Electrical Equipment:

- Speed-regulated drive, total connected load of the machine: 7.5 KW

- Voltage: Three phase 380V±10% power supply

- Main power cord requirements: However the power cord of it should be not less than 4m㎡ three-phase four-core.

- Ground wire: not less than 6m㎡

Oil Supply:

- Heating and cooling through using an air to air heat exchanger to circulate air and filter that has dirt detection feature.

Optional: Heat exchanger for water conditioning plants

Equipment Working Conditions:

- Temperature: 25℃±3℃

- Humidity: 65%±10%

- Floor pressure: 2000-4000KG/㎡

Training & Service

Installation & Training

Our technical support includes global training in warp knitting machines via manuals, video libraries, and on-site programs, with local teams in five countries.

Local Service

Grandstar optimizes machine reliability with on-site services in Turkey, India, Vietnam, Indonesia, and the USA, supplemented by proactive performance checks.

Application

- Elastic and Rigid Lingerie: Perfect for crafting intricate designs with precise elasticity or rigidity, enhancing comfort and elegance.

- Corsetry: Produces durable and detailed patterns suitable for high-end corsets and structured undergarments.

- Decorative Lace Fabrics: Ideal for spot nets, tulle, and lace-like textiles used in bridal wear and decorative applications.

- Sportswear: Creates high-performance fabrics with excellent stretch and durability, ideal for athletic and activewear.

- Home Textiles: Manufactures sophisticated designs for curtains, upholstery, and other decorative household fabrics.

- Shoes and Accessories: Designs sturdy, breathable materials for shoe uppers and fashion accessories.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |