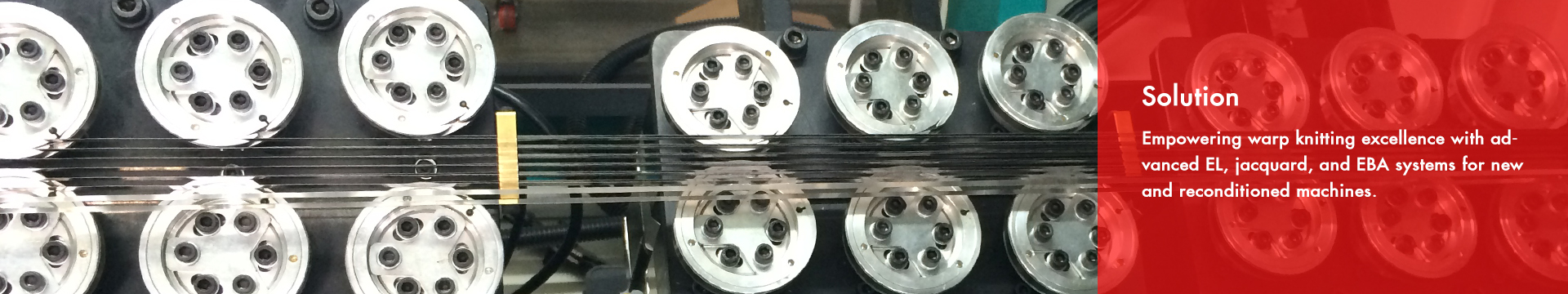

Let-off system

| Category | Solutions |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DRAWINGS

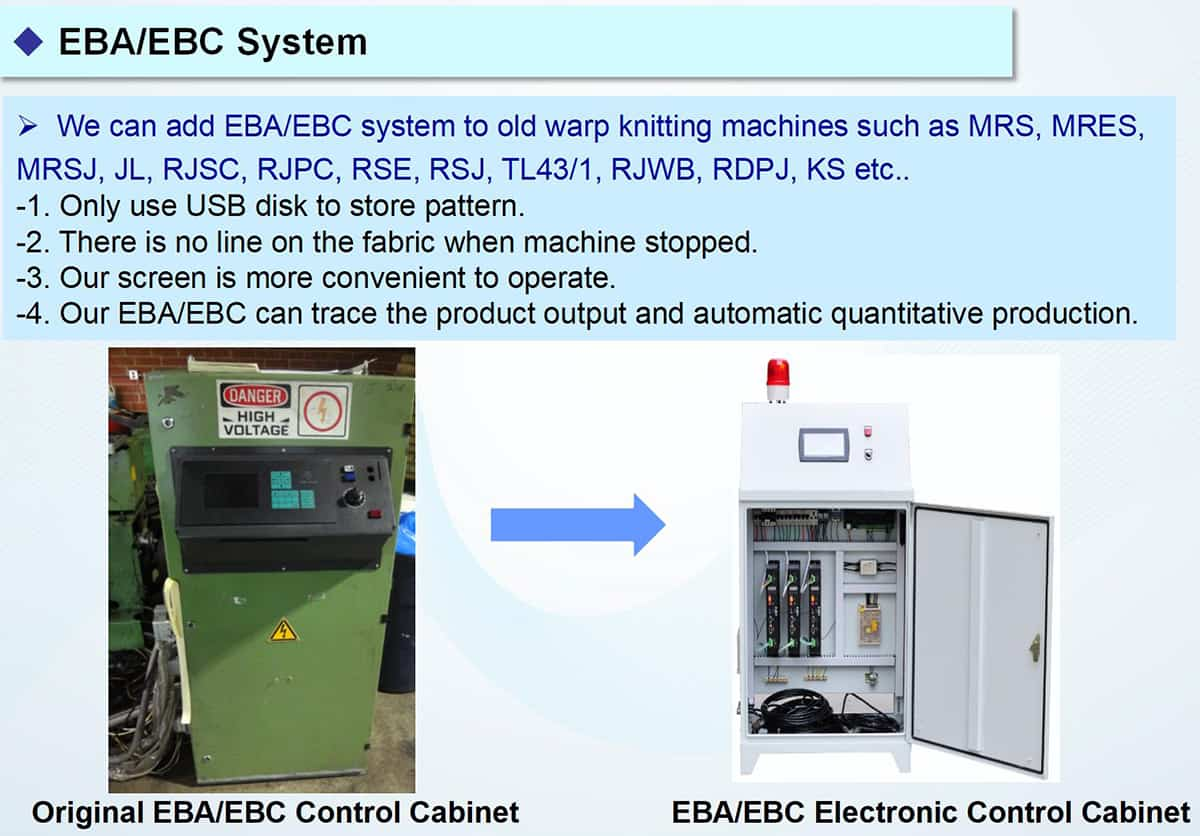

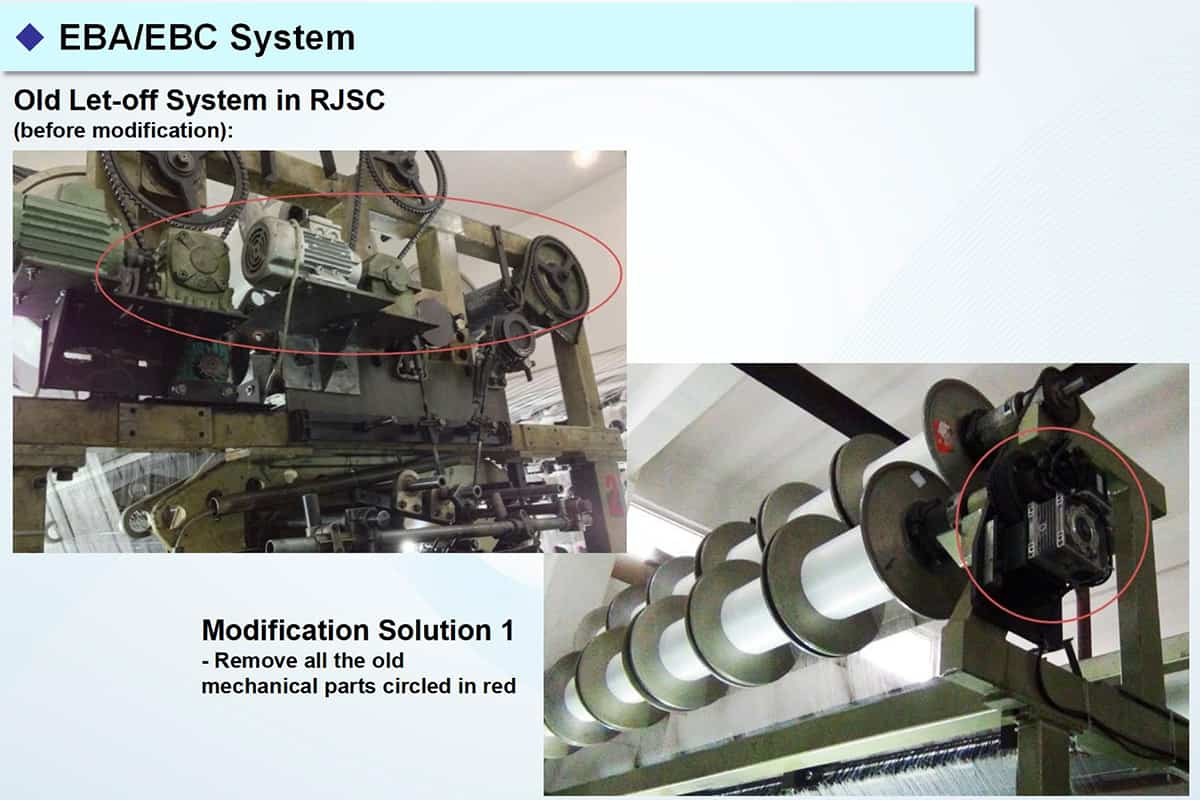

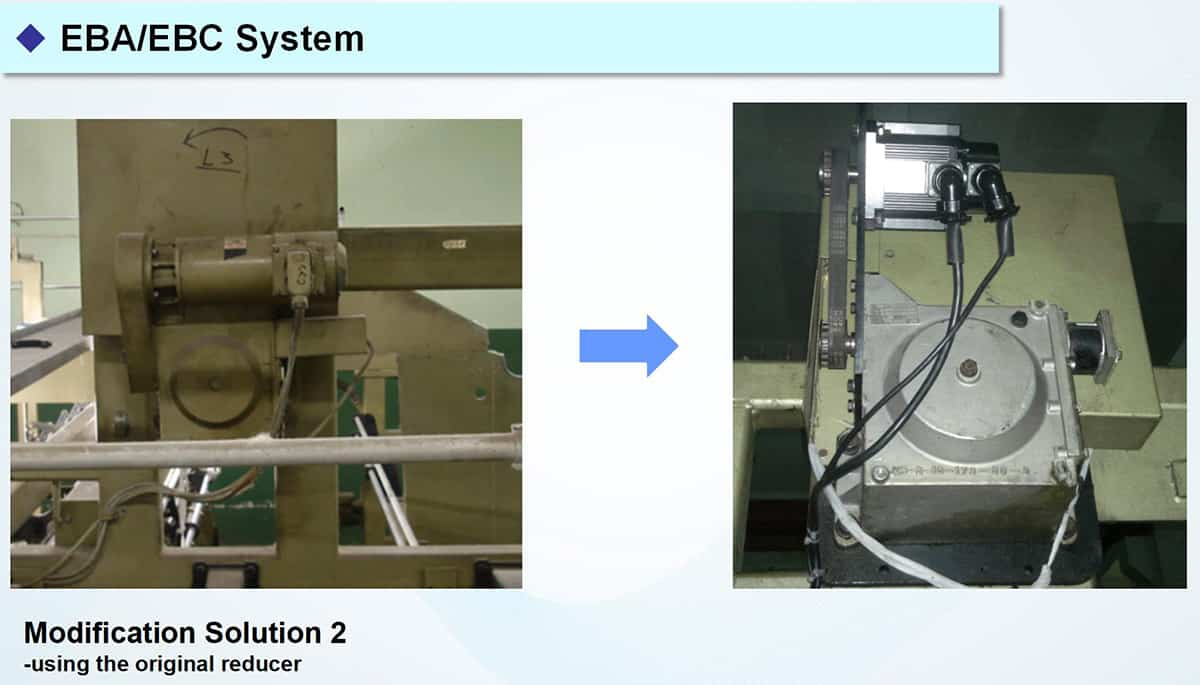

1. Bringing Old Machines into the Present Time

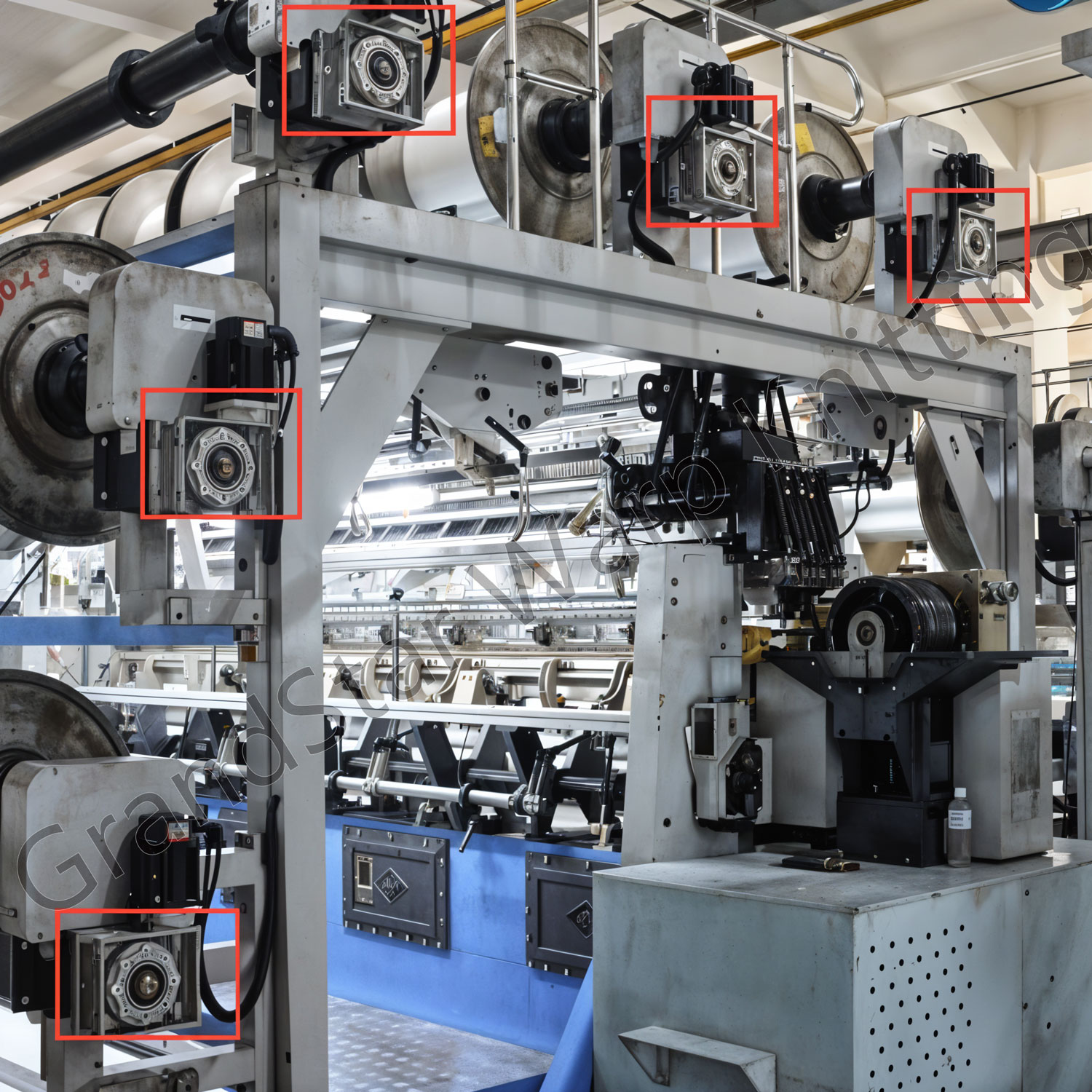

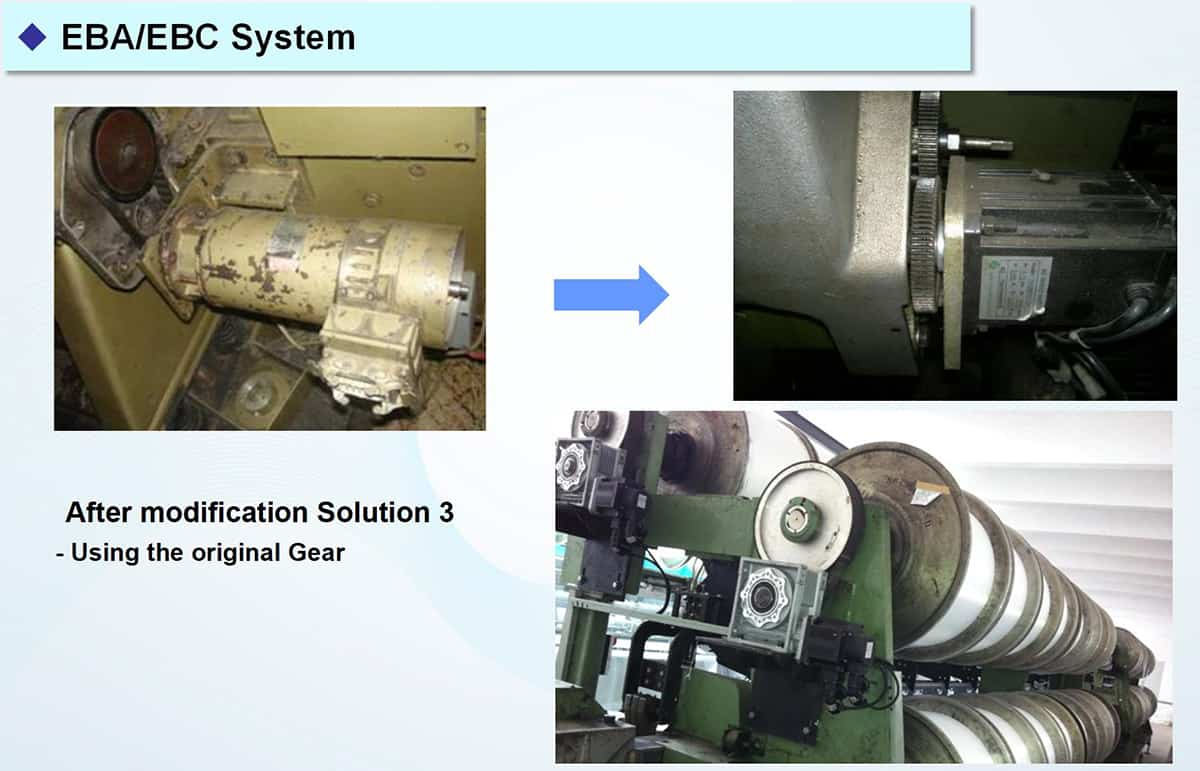

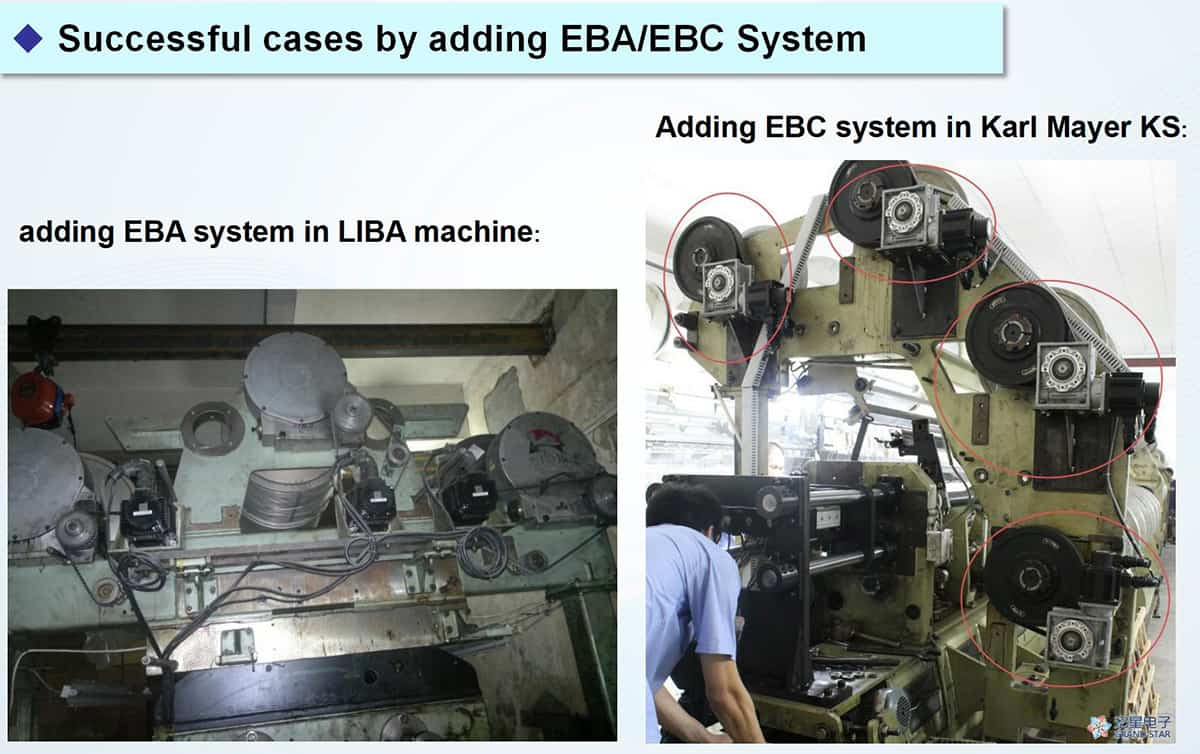

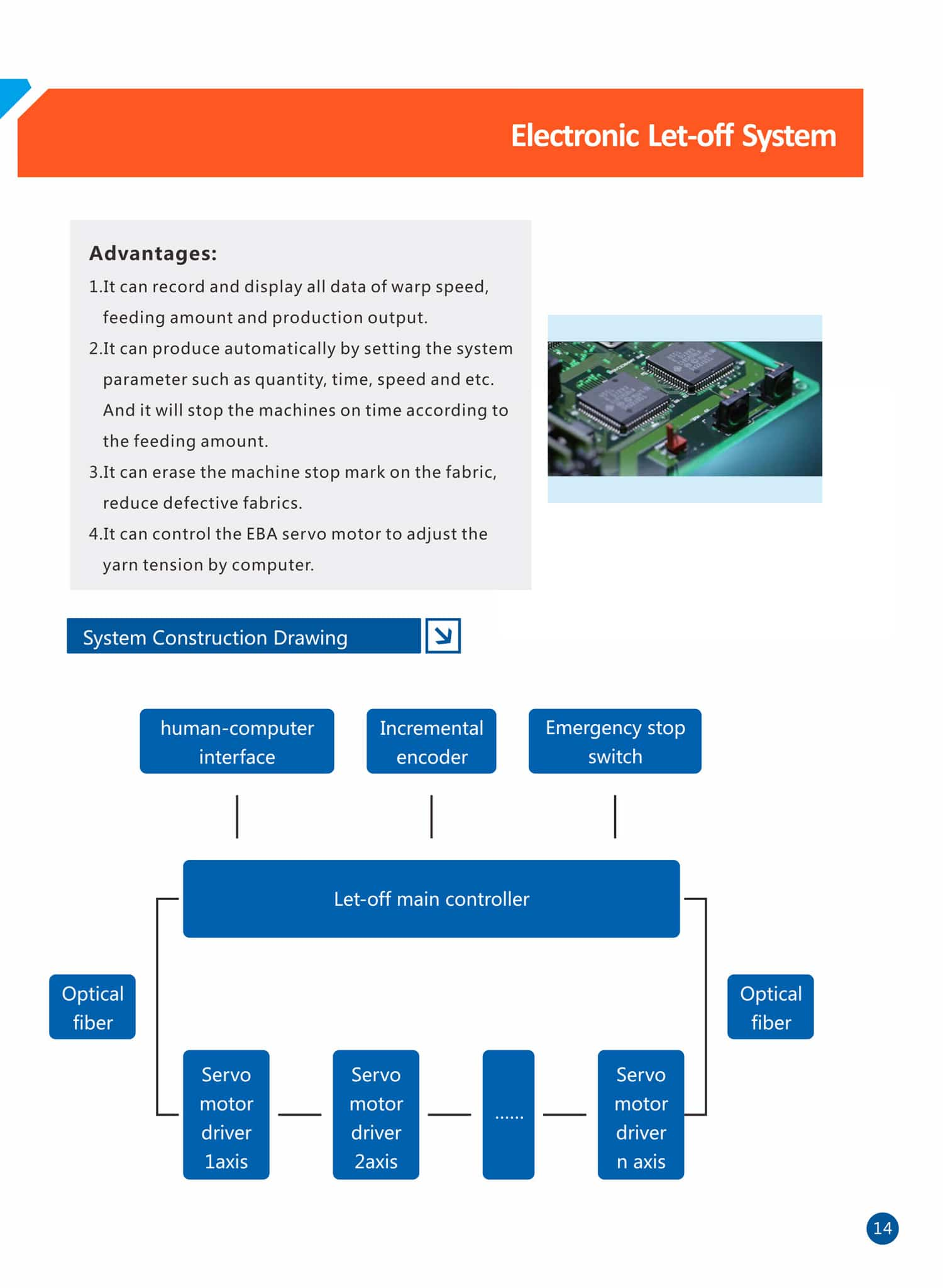

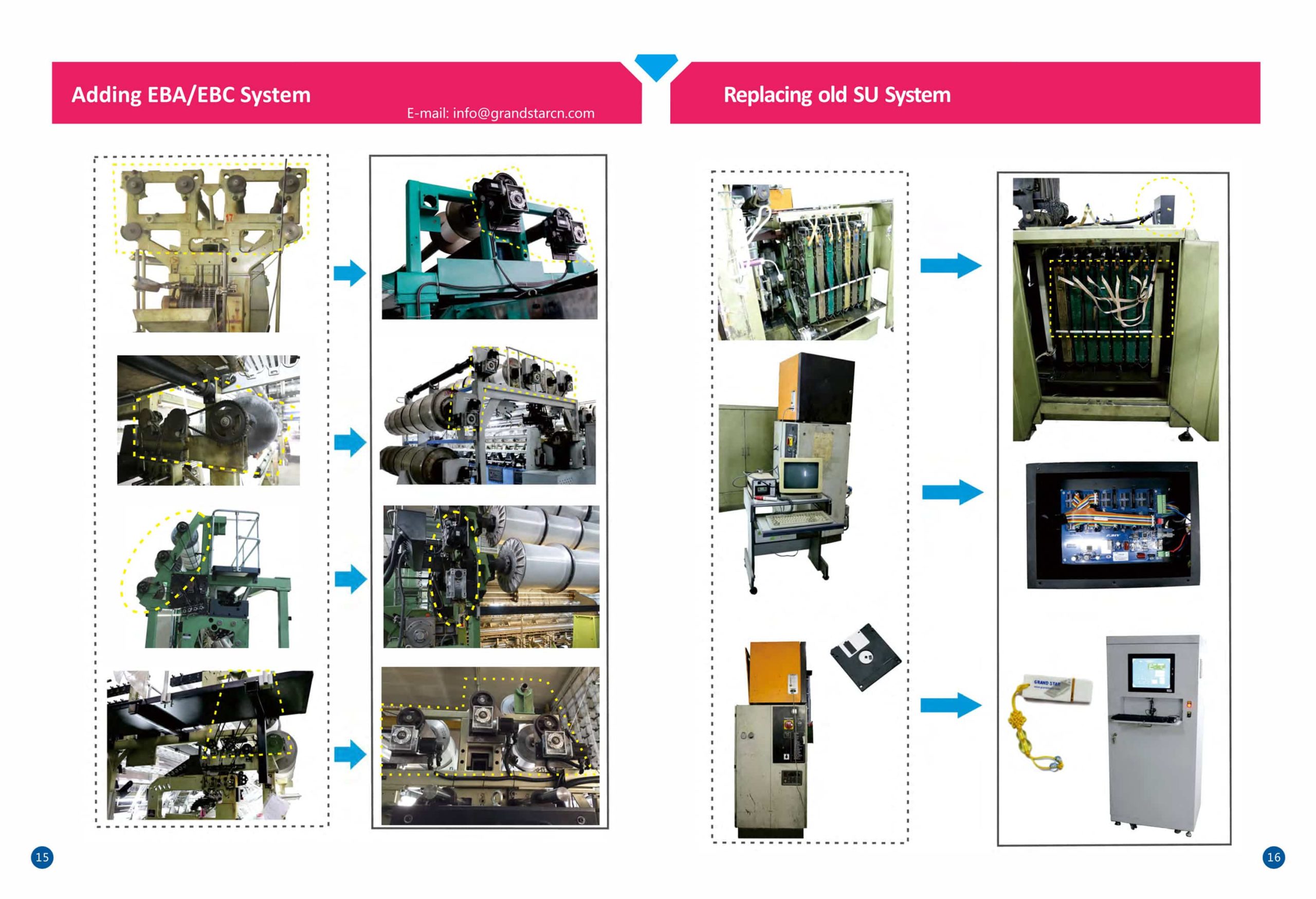

The EBA/EBC system rejuvenates older warp knitting machines by replacing a mechanical Let-Off system that is now old fashioned with an innovative electronic Let-Off system. Making these upgrades improves the overall operation precision, tightens organization’s production cycles and prolongs life span of those machines, allowing companies to work more efficiently with out having to acquire all new machinery.

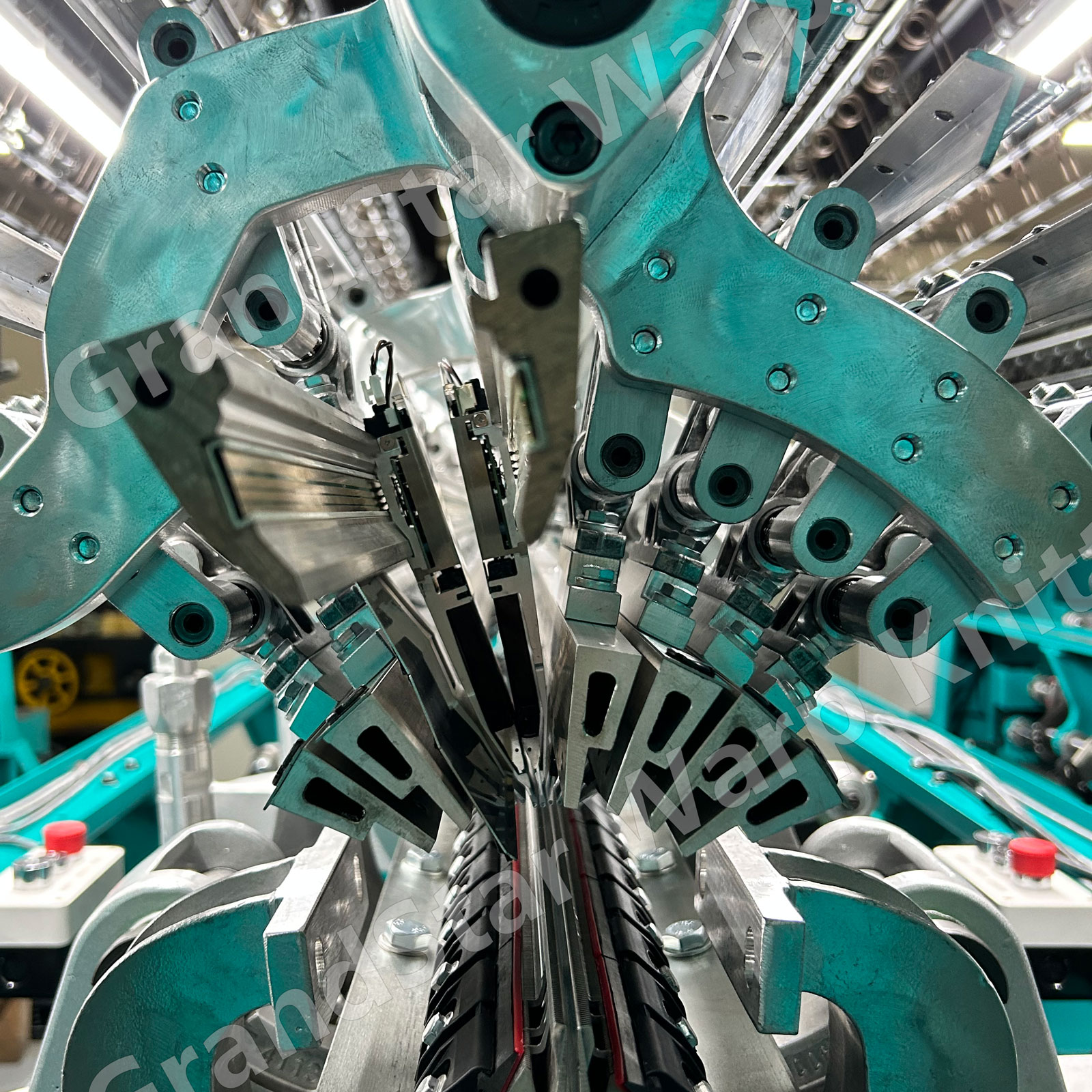

2. High precision with stop compensation technology

Another aspect of the new system is the stop compensation mechanism which prevents formation of horizontal stripes on the fabric during emergency stops . This feature ensures that this product provides high quality production regardless of pace set within the textile manufacturing industries making it the best to buy.

3. Compatibility of High-Speed Tricot Machine

Designed to withstand the high speed requirement of today’s warp knitting the EBA/EBC system is suitable for Tricot machines that are above 4,500 nowrap R.P.M. The smooth integration with the system also promises excellent efficiency and stability especially in operations of both Tricot and warp knitting machines.

4. High-Powergroup for Large Beams

For high electrical power configurations, the system could deal efficiently with warp knitting machines possessing large beams from 390-inch beams to forty inches beams. This strong configuration gives high-speed and efficient performance that fits the need of production requiring high throughput.

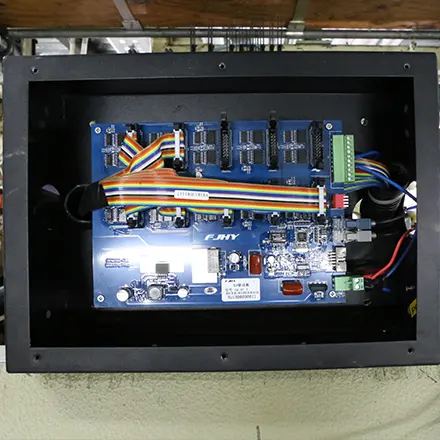

5. Application of IoT Integration and Future-Ready Technology

The new EBA/EBC system adapts for the era of digital interconnectivity through IoT in transmitting the data for immediate monitoring and decision making. Also, it has USB storage capabilities, that allow for data transfer, which makes this solution rather progressive for today’s manufact

Application

- Revitalizing Legacy Machines: Perfect for upgrading older warp knitting machines to improve efficiency and extend their operational lifespan.

- High-Speed Tricot Knitting: Ideal for use in Tricot machines exceeding 4,500 RPM, delivering reliable, high-quality production at faster speeds.

- Large Beam Operations: Designed for machines handling heavy-duty beams, supporting seamless production in industries requiring high yarn tension and load capacity.

- Technical and Industrial Textiles: Ensures precision and consistency in producing technical fabrics like automotive textiles, medical fabrics, and protective gear.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |