Machine Tricoter with 4 guide bars

| Tricot Machine with 4 guide bars HKS4 – Warp Knitting Machine | |

| Model No. | GS-HCOP 4K+E |

| Ground Bars | 4 Bars |

| Pattern Drive | EL Drives |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

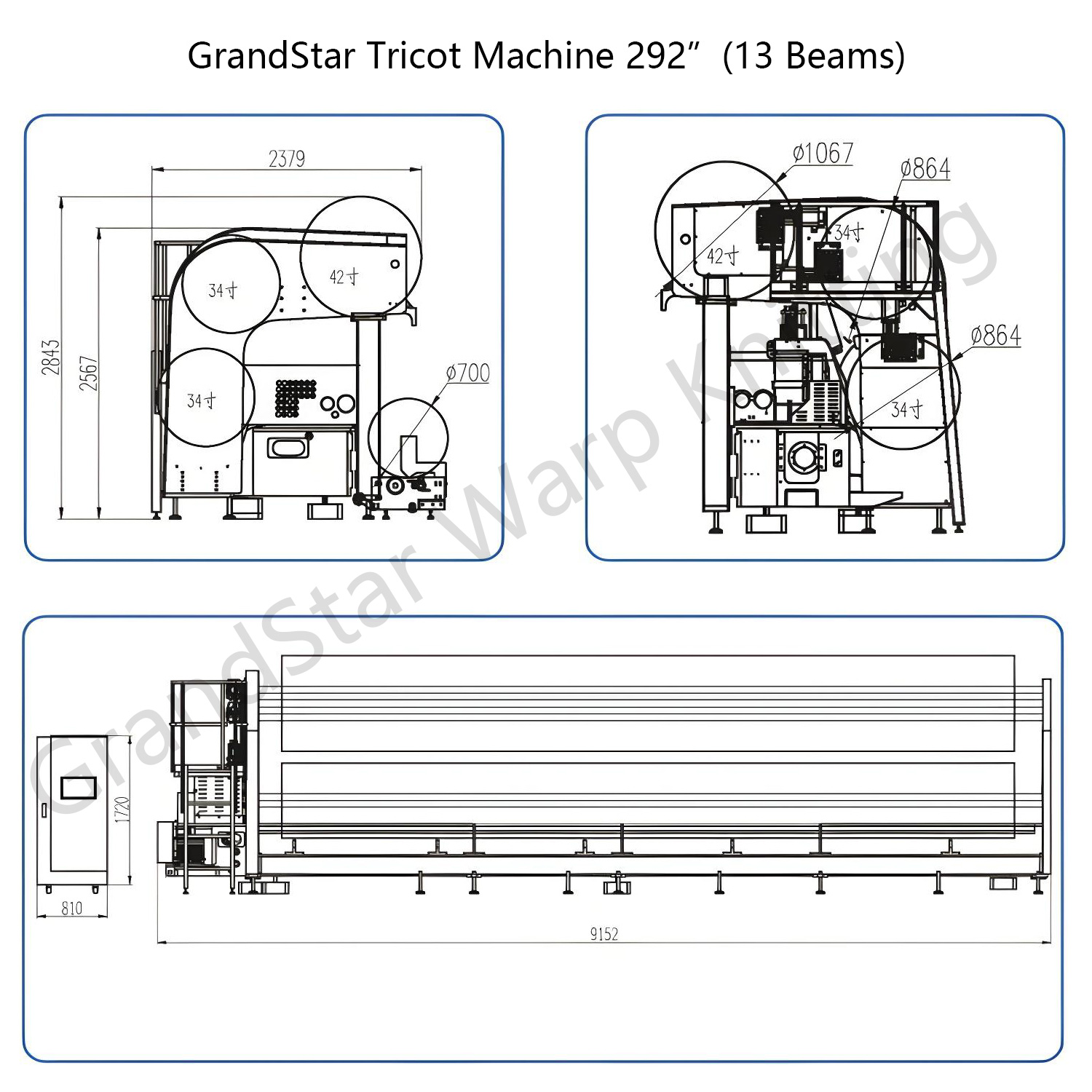

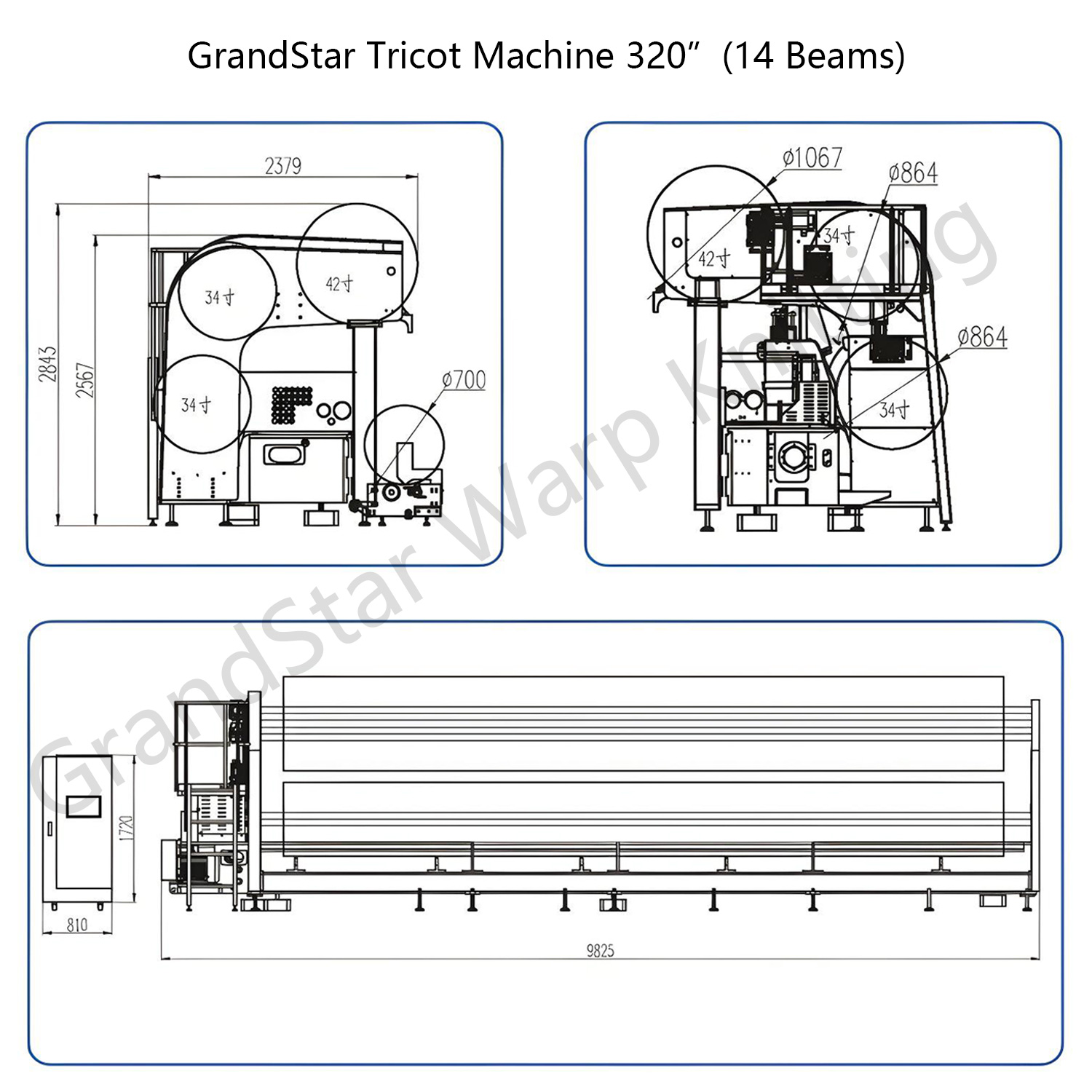

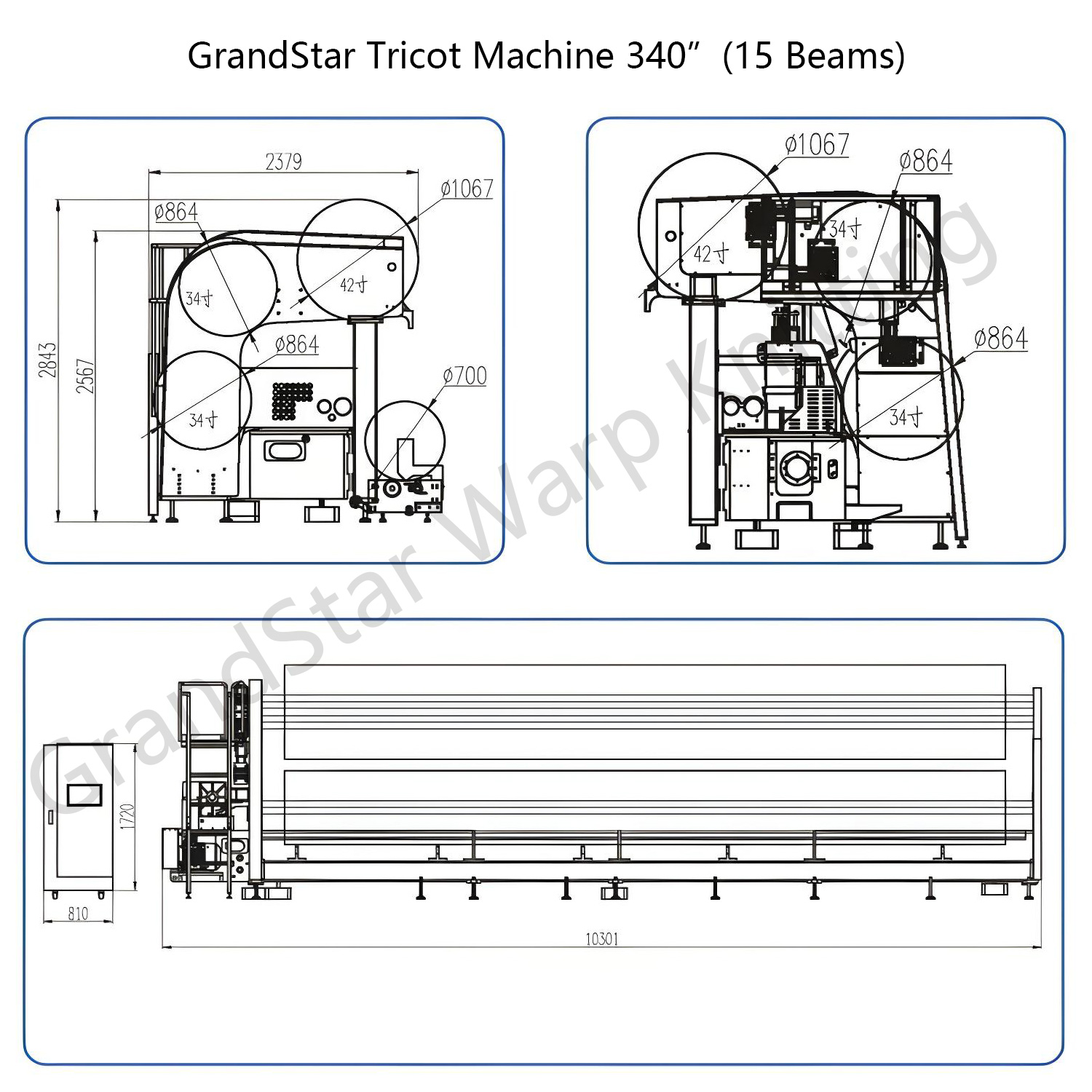

- TECHNICAL DRAWINGS

-

Bars / Knitting Elements: The machine boasts an individual needle bar with compound needles, a slider bar with plate slider units (½”), and a sinker bar with compound sinker units. Two guide bars, each with guide units, ensure high-quality, efficient fabric production.

-

Warp Beam Support: Designed for flexibility, it supports multiple warp beam configurations, including 4 × 812 (32″) free-standing, and options for varying sizes (up to 40″).

-

Fabric Take-Up System: The electronically regulated fabric take-up is driven by a geared motor and includes four rollers for uniform tension control, ensuring consistent fabric quality.

-

Integrated Monitoring Systems: Equipped with integrated Laserstop and a camera for real-time fabric inspection, this ensures minimal waste and maximum quality.

-

Pattern Drive Options: The machine comes with an N-drive system featuring three pattern discs, plus an optional EL-drive for more advanced functionality. This setup allows guide bars to shog up to 50 mm, with the potential for an increased distance of up to 80 mm.

-

Electrical Equipment: The machine is powered by a speed-regulated drive, with a total connected load of 25 kVA. It operates on a 380V ±10% three-phase power supply and requires a three-phase four-core power cord.

-

Working Conditions & Specifications: The machine operates optimally at a temperature range of 25℃±6° and 65%±10% humidity. It requires floor pressure between 2000-4000 KG/㎡ and can be configured with working widths of 7366 mm, 8128 mm, and 8636 mm.

Training & Service

Installation & Training

We offer training in multiple formats, including on-site sessions in over 20 countries and dedicated local teams in key regions like Turkey, India, and the USA.

Local Service

Our after-sales service spans Turkey, India, Vietnam, Indonesia, and the USA, with plans for expansion. In regions without local teams, real-time online support is the first line of assistance, followed by dispatching engineers for hands-on support if necessary.

Application

-

Fashion Textiles: This machine is ideal for producing lightweight, breathable fabrics commonly used in apparel such as dresses, blouses, and lingerie.

-

Sportswear and Activewear: Tricot knitting technology is widely used for fabrics designed for sportswear, offering excellent elasticity, moisture-wicking properties, and comfort for athletes.

-

Medical and Technical Textiles: The machine’s precision and versatility allow the creation of specialized fabrics for medical applications, such as bandages, compression garments, and wound care materials.

-

Home Textiles: The Tricot Knitting Machine is perfect for creating high-quality upholstery fabrics, curtains, and bed linens with various textures and designs.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |