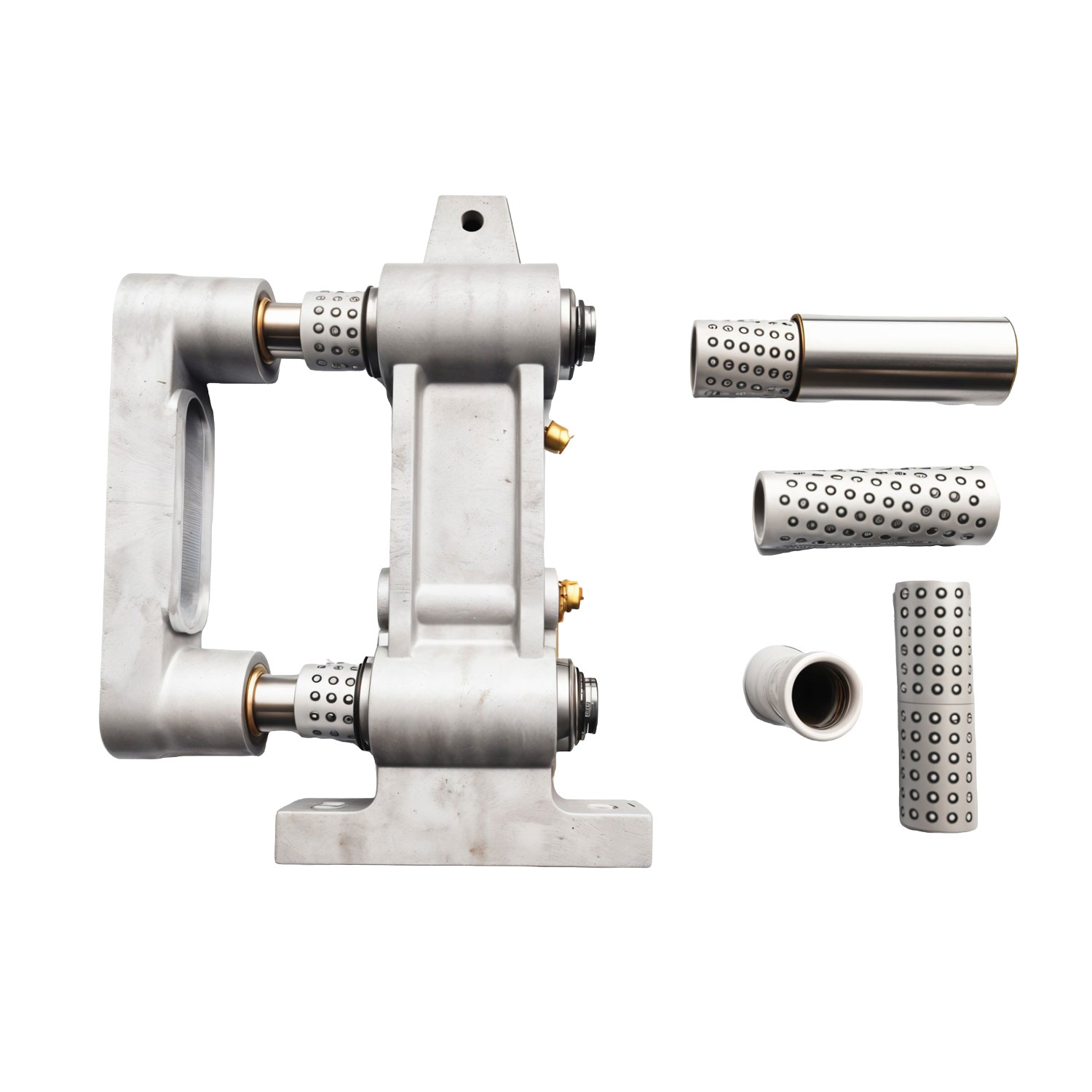

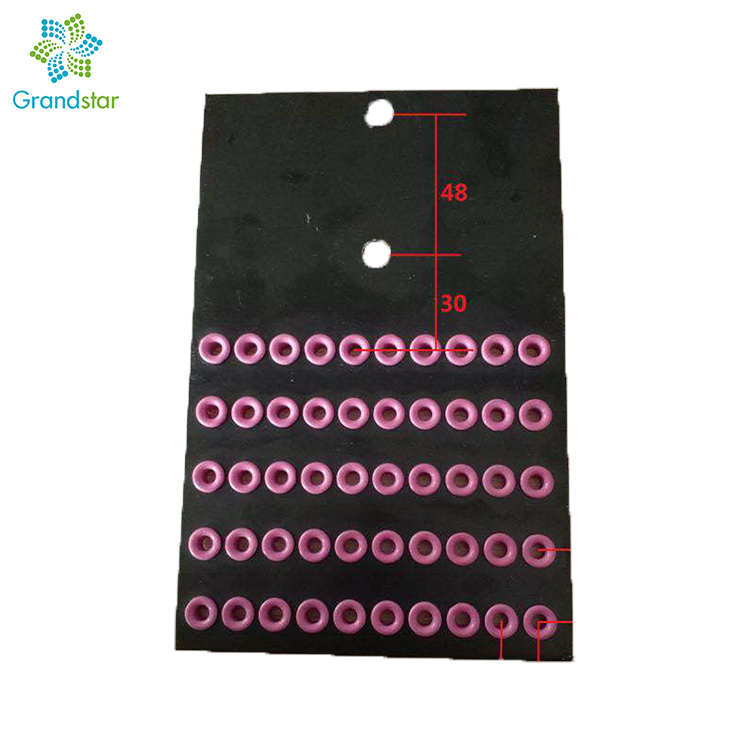

Mechanical Parts

Warp knitting machines are equipped with several key mechanical parts that ensure efficient fabric production. These include needles, which form the loops, guide bars that control yarn movement, sinkers that help maintain fabric tension, and cam shafts responsible for precise needle and yarn positioning. Other components like crankshafts, latches, and beat-up bars also play vital roles in fabric consistency and quality. Together, these parts work in sync to create intricate, durable, and uniform textiles used in a wide range of applications, from apparel to industrial fabrics. Proper maintenance of these components is essential for optimal machine performance.