From Fiber to Fabric: The Smart Non-Woven Warp Knitting Machine

The textile industry is changing. New machines help make work easier and faster. One important tool is the non-woven warp knitting machine. It helps mix quality with speed. More people want better fabrics. They also want to make them in a way that does not hurt the planet. The non-woven warp knitting machine helps meet these needs. It works fast and uses less waste. So, it saves time and energy.

Also, this machine is easy to use. It makes strong fabrics that last long. Many companies now choose it to stay ahead in the market. Each day, more factories turn to smart machines. They want to make better products and lower their costs. The non-woven warp knitting machine is part of this big change. So, how can this machine help your business grow? Let’s find out more about it!

What is a Non-Woven Warp Knitting Machine?

Combines Speed and Simplicity

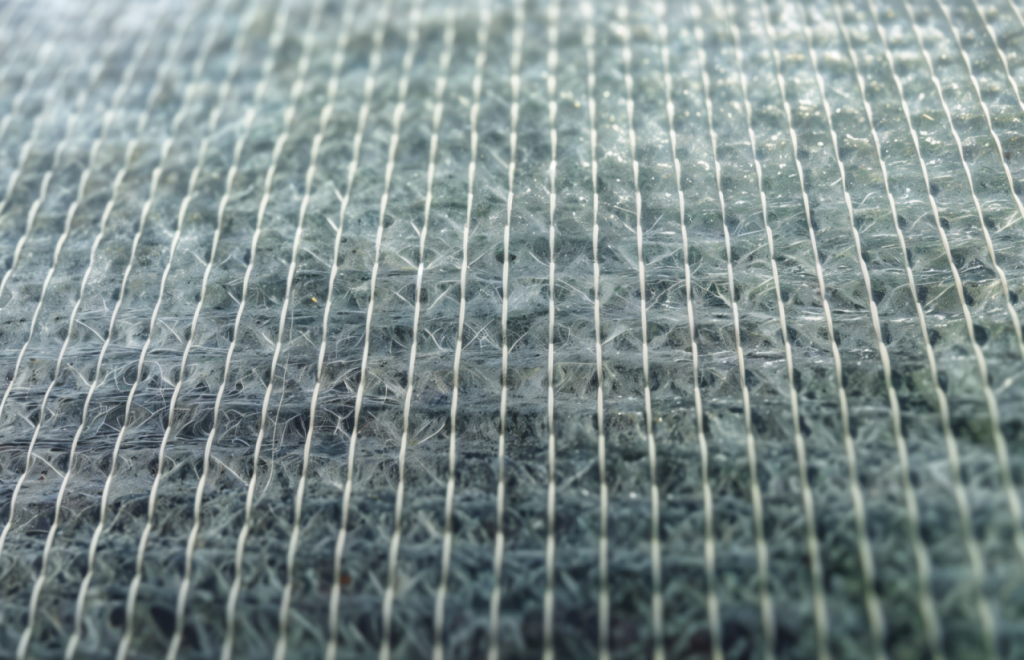

A non-woven warp knitting machine works fast. It combines the speed of warp knitting with the simple steps of non-woven fabric making. It does not need spinning. It does not need weaving. The yarn is placed directly into the machine. The machine stitches it into fabric. This saves time. It also lowers the number of steps in production.

Makes Stable Fabric with Many Yarns

The machine uses many yarns. These yarns are placed in the warp direction. They are lined up straight. The machine knits them to form a firm and strong fabric. The fabric stays flat. It does not shift or stretch much. This makes the fabric good for products that need shape and hold.

Works in Many Industries

This machine is used in many fields. It helps make car seat covers and trunk linings. It also makes soft materials for hospitals. People use it to make home fabrics like curtains and tablecloths. It is also used in geotextiles. These go into soil or roads to help support the ground. A non-woven warp knitting machine can be used in both light and heavy work.

Meet Grand Star Technology: Precision You Can Trust

Who We Are

Grand Star Technology builds non-woven warp knitting machines. The company started in 2012. It is based in Fuzhou, Fujian. The team has more than 50 skilled staff. They work on research, design, and machine building. Every part is made to fit well and last long. The machines are made to work in real production lines.

Growth Through Experience

Grand Star has grown with time. The company serves clients in many countries. These include the United States, Japan, Turkey, Vietnam, Indonesia, India, Colombia, and Mexico. The team has strong skills. They keep trying new ideas. They test each machine before it ships. This helps build trust with global clients. The non-woven warp knitting machine is one of their top products.

What Sets Us Apart

Grand Star is known for quality and service. The machines are easy to adjust. They can be made to fit different jobs. The company also gives strong support after the sale. Clients can get help by phone, online, or in person. Grand Star works hard to make sure each machine keeps running well.

Why “Smart“ Matters in Modern Fabrication

Smart Control Helps You Work Better

A non-woven warp knitting machine from Grand Star uses sensors. These sensors watch the yarn tension. This keeps the tension steady. It also stops extra waste. The machine is run by a computer system. It controls the drive, the yarn feed, and the fabric pull. The operator can see the settings on a touch screen. This makes it easy to watch the machine and fix problems fast.

Flexible Settings for Easy Change

The machine has programmable controls. This means you can change the design fast. You do not need to stop the machine for long. There is a separate batching device. It has a roller and friction drive. It holds fabric rolls up to 914mm wide. A geared motor helps with smooth speed control. This helps keep the fabric even.

More Uptime, Less Repair

The machine checks itself while running. It shows errors on the screen. This helps the operator find problems quickly. Fast fixes mean more production. It also means fewer long stops. The smart system helps reduce repair time. The machine can run longer with fewer breaks. A non-woven warp knitting machine like this helps factories work faster and better.

Key Features That Set It Apart

Fast Speed and Clear Output

The non-woven warp knitting machine runs at high speed. It makes fabric quickly. The fabric stays smooth. It does not stretch or twist. The machine is made for stable output. It offers many working widths. You can choose from 2000mm, 2800mm, 3600mm, 4400mm, 4800mm, 5400mm, or 6000mm. There are also different gauges. These include F7, F12, F14, F16, F18, F20, and F22. This gives more control over the fabric size and thickness. The machine fits many types of production needs.

Low Power Use and Smooth Yarn Feeding

The non-woven warp knitting machine uses less energy. The yarn feeding system is built for less waste. It uses an N-drive with a pattern disc. This keeps the stitching clean and even. The gear system can change tempi. This means better motion control. The warp beam can hold one or two beams. This makes it good for both small and large jobs. The flange size can go up to 30. These features help save energy and time.

Flexible Design with Smart Upgrades

The machine has a modular design. This means it is easy to upgrade. You can change parts when needed. The yarn let-off device is electronic. It uses a geared motor with a speed control system. This gives steady yarn flow. The yarn stop motion is also available as an option. It can be controlled electronically. The fabric take-up system is also electric. It uses a geared motor and a speed converter. This setup helps the machine run with better control and less downtime.

Industry Impact and Sustainable Edge

Less Labor, More Output

The non-woven warp knitting machine does not follow old weaving steps. It skips spinning and weaving. It uses direct yarn input. This lowers the need for skilled labor. The machine does more of the work. This helps reduce extra steps. The result is faster output and lower labor costs.

Saves Materials and Cuts Waste

This machine supports clean production. It uses less raw material. It also makes less waste. The yarns go directly into the fabric. There is no glue or heat needed. This makes the process smooth and safe. The clean process helps factories follow green rules. The machine helps save cost and protect the planet.

Supports Global Green Goals

Many companies want to meet new eco rules. They look for machines that help the planet. The non-woven warp knitting machine fits that goal. It uses less energy. It saves materials. It runs clean and fast. These things help support world plans for cleaner textile work. More and more factories now use this machine to stay ahead.

Looking Ahead: The Fabric of the Future

Smarter Machines with AI and IoT

New non-woven warp knitting machines will use AI and IoT. These tools will help the machine learn and adjust. The machine will watch its own settings. It will fix small problems by itself. This helps reduce stops and saves time. Predictive maintenance will also become easier. The system will know when parts need care.

More Use in New Textile Fields

These machines will soon be used in new areas. They will help make smart fabric and high-tech textiles. These fabrics will be used in sports, safety gear, and tech clothes. The machine is ready for that shift. It can handle soft and strong yarns. It can also make light or thick fabric.

Grand Star Builds the Future

Grand Star keeps working on new ideas. The team puts time and money into research. We want to keep building better machines. We study what the market needs. Then we test and improve each model. Every new non-woven warp knitting machine is made with care. The goal is always quality, speed, and smart design.

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.