Pattern Disc

| Pattern Disc / Pattern Disk For Warp Knitting Machine | |

| Model No. | Pattern Disc |

| Application | For Waste Yarn Collection |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

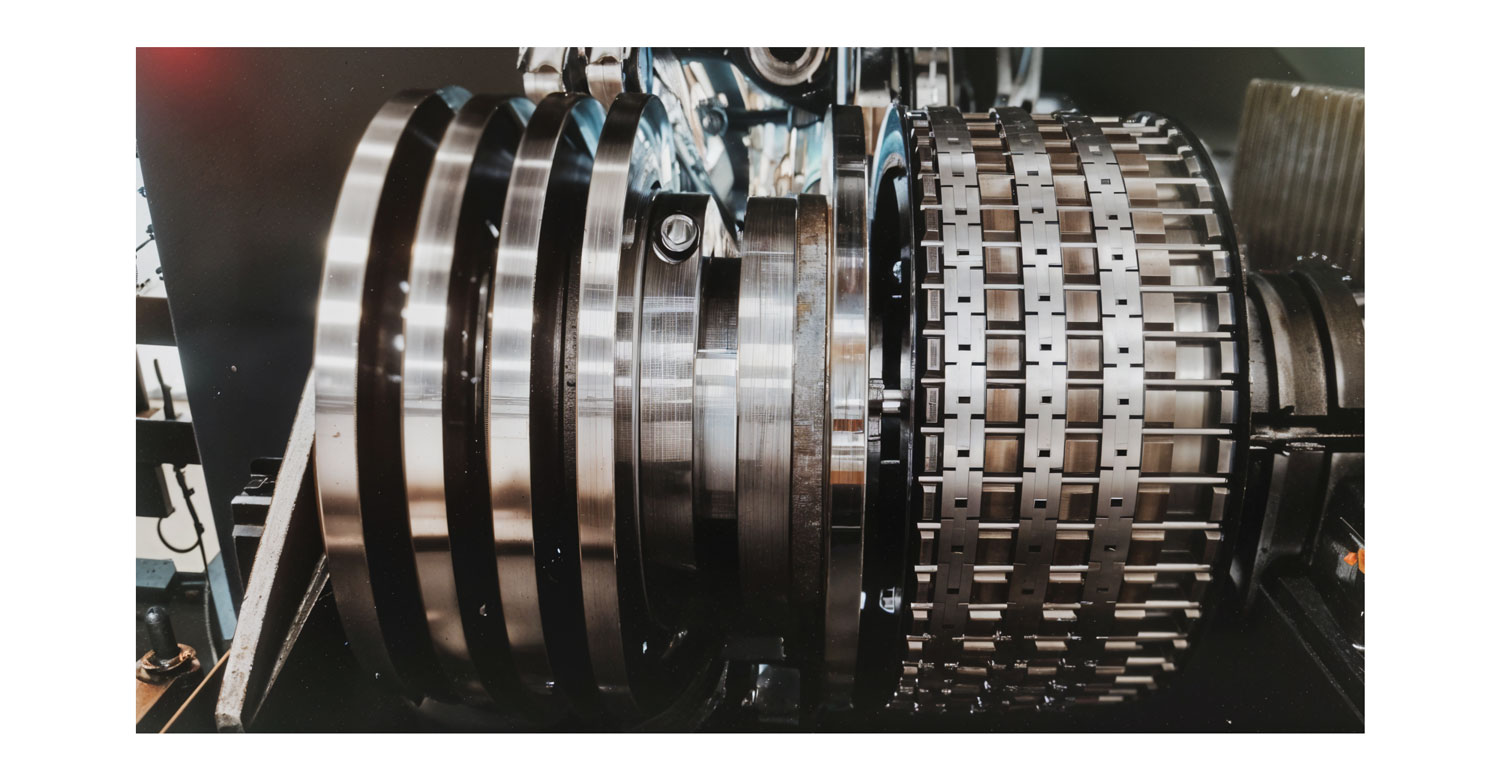

High-Performance Pattern Disc for Warp Knitting Machines

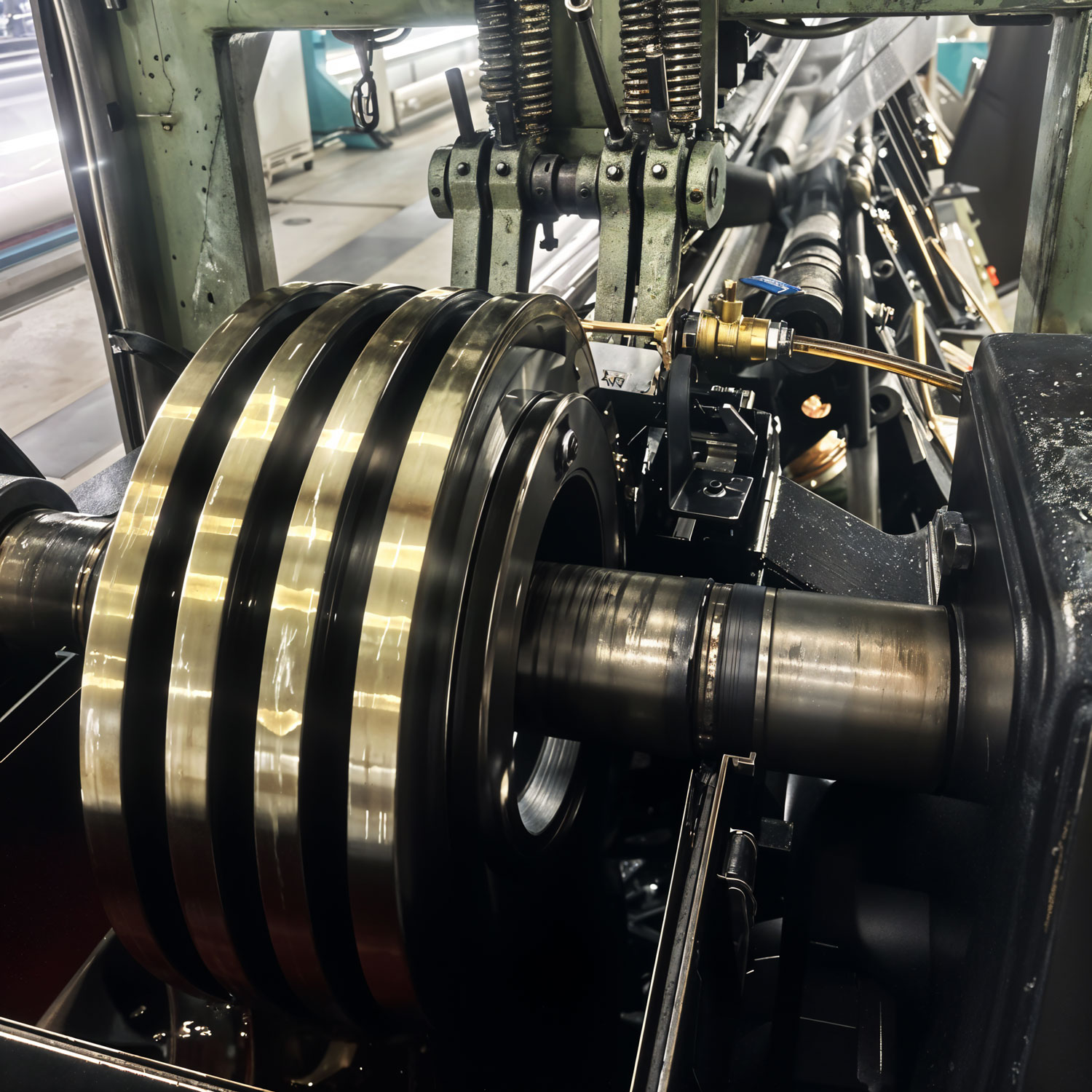

In the world of warp knitting, precision, durability, and cost-efficiency are key factors influencing production success. Among the two main warp knitting machine drive shog types—Pattern Disc and EL Type—the Pattern Disc remains the most economical and widely chosen solution, especially for manufacturers specializing in fixed-design production. Our premium-grade pattern discs are engineered to outperform competitors in both durability and customization.

Why Choose Our Pattern Discs?

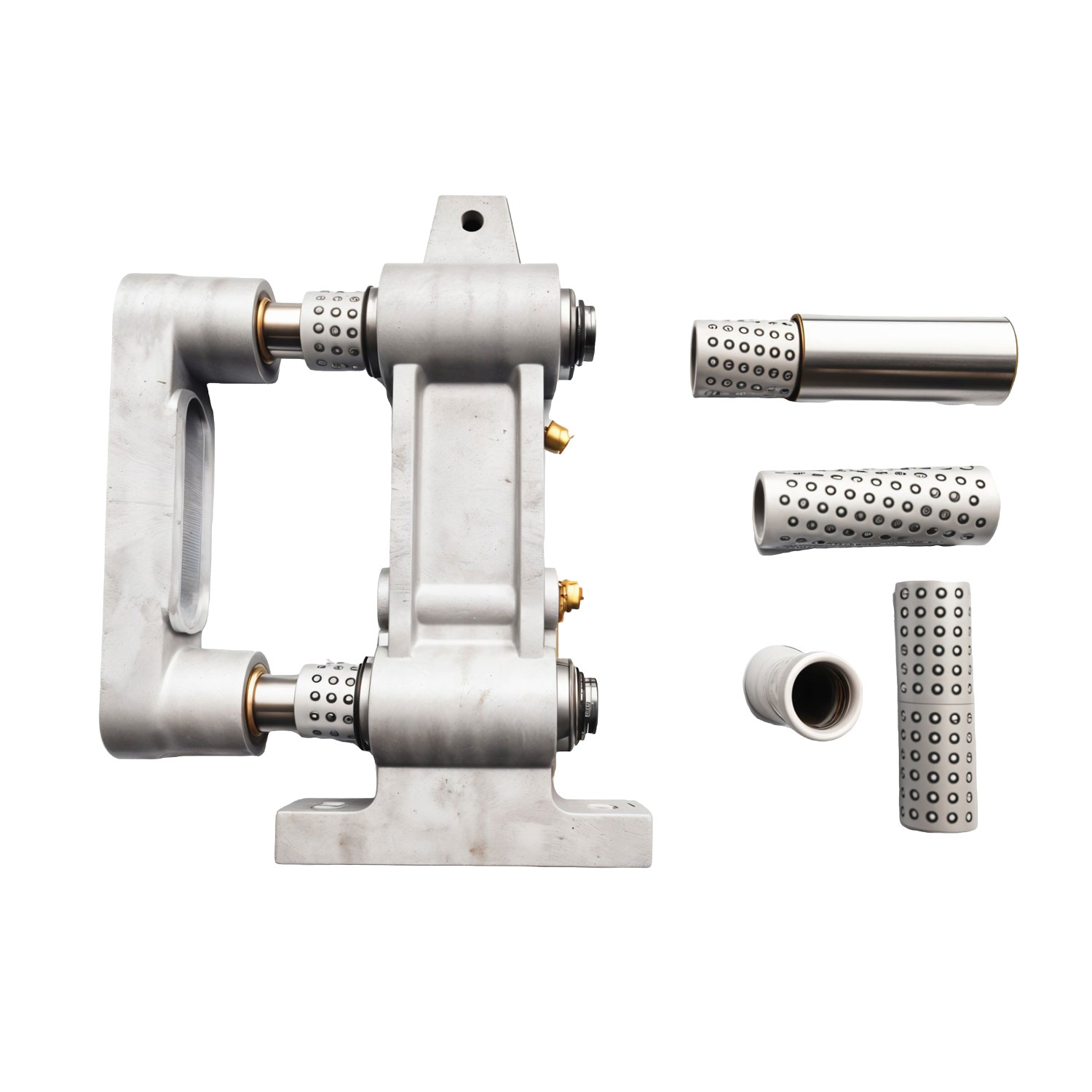

- Unrivaled Customization: We provide tailor-made pattern discs for a variety of warp knitting machines, including tricot machines (HKS 3, HKS 4, KS2), terry towel warp knitting machines, double needle bar warp knitting machines, and Liba warp knitting machines. Whether your process requires tempi 12 or tempi 10, we ensure precise manufacturing to meet your specific needs.

- Superior Heat Treatment: Unlike standard discs on the market, our advanced heat treatment process enables our pattern discs to withstand extreme operating speeds of up to 3500 RPM, ensuring exceptional durability and stability during high-speed production.

- Precision Engineering for Seamless Operation: Our pattern discs are meticulously designed with accurate positioning holes on both sides, facilitating easy installation and seamless integration into existing systems.

- Comprehensive Chain Block Solutions: We offer a complete range of N, E, and H chain blocks, ensuring that customers receive an all-inclusive solution for their warp knitting machinery.

Enhance Efficiency and Reduce Costs

By choosing our pattern discs, manufacturers benefit from a cost-effective solution without compromising on performance and longevity. Our innovative approach to design and material selection ensures that customers experience minimal downtime, reduced maintenance costs, and higher production efficiency.

Invest in Quality – Optimize Your Production

We specialize in producing high-quality, precision-engineered pattern discs and chain blocks that set new industry benchmarks. With our expertise in warp knitting technology, we empower textile manufacturers to enhance their output while maintaining exceptional quality standards.

Contact us today to discover how our advanced pattern discs can transform your warp knitting production.

Application

🔹 Versatile Applications in the Textile Industry

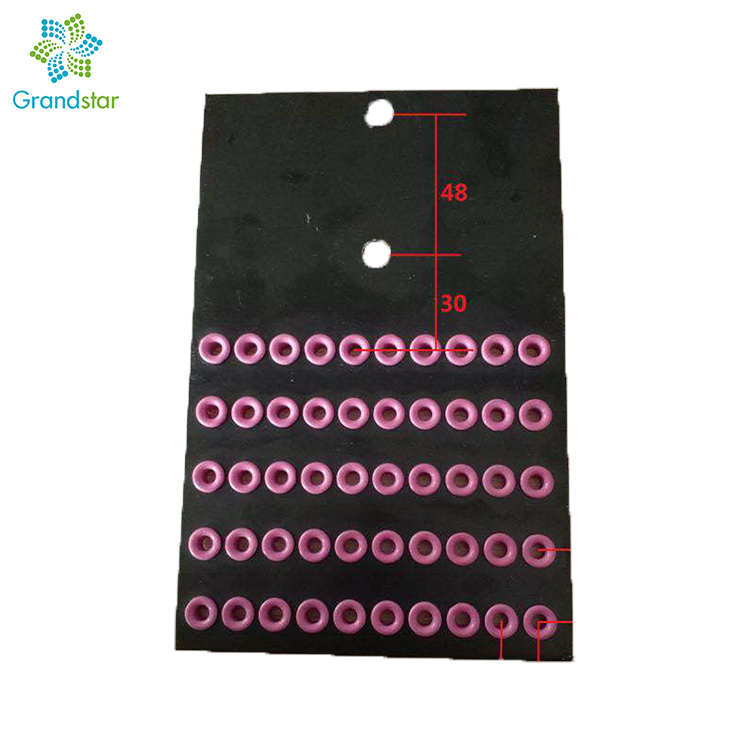

The KFD Yarn Tensioner is an indispensable component in diverse textile manufacturing processes, including:

- Warp Knitting: Guarantees uniform tension for high-performance technical textiles and intricate warp-knitted designs.

- Traditional Weaving: Optimizes yarn control in conventional weaving looms, enhancing durability and texture consistency.

- Circular Knitting: Ensures seamless, high-quality fabric production by regulating yarn tension with precision.

🚀 Elevate Your Warp Knitting Performance with KFD Yarn Tensioner

By integrating the KFD Yarn Tensioner into your textile production line, you gain a competitive edge with superior fabric quality, increased efficiency, and cost savings. Experience the next generation of warp knitting tension control—where precision meets performance.

Patterner Disc Order Form

Please fill in the required fields accurately. Our team will review your order and contact you for confirmation.

| Field | Customer Input | Example |

|---|---|---|

Model |

RSE 4-N-1 | |

Machine Serial Number |

72676 | |

Gauge |

E32 | |

Bra’s Number |

GB 2 | |

Ratio |

12:1 | |

Chain Link Number |

1-2/1-0/1-2/2-1/2-3/2-1// | |

Machine Speed |

1350 |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |