Raschel Jacquard RSJC 5/2

| Raschel Jacquard RSJC 5/2 For Rigid Farics – Warp Knitting Machine | |

| Model No. | RSJC 5/2 (EL) |

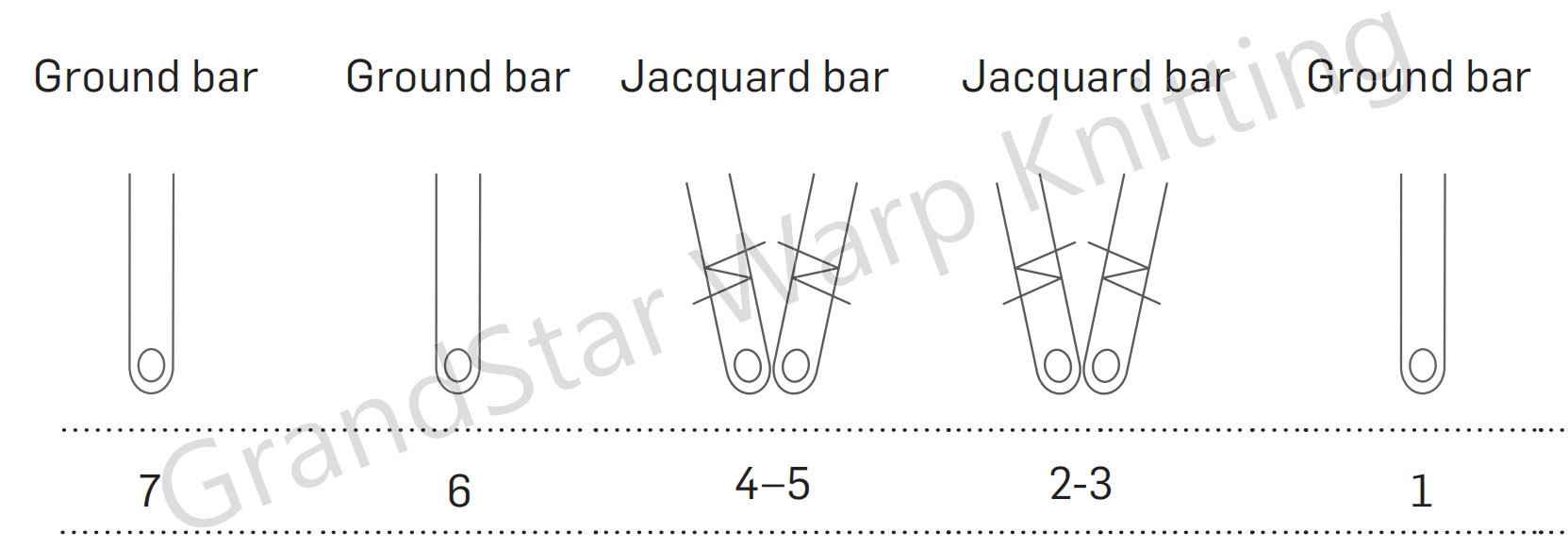

| Ground Bars | 3 Bars |

| Jacquard Bars | 2 Groups (4 Bars) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

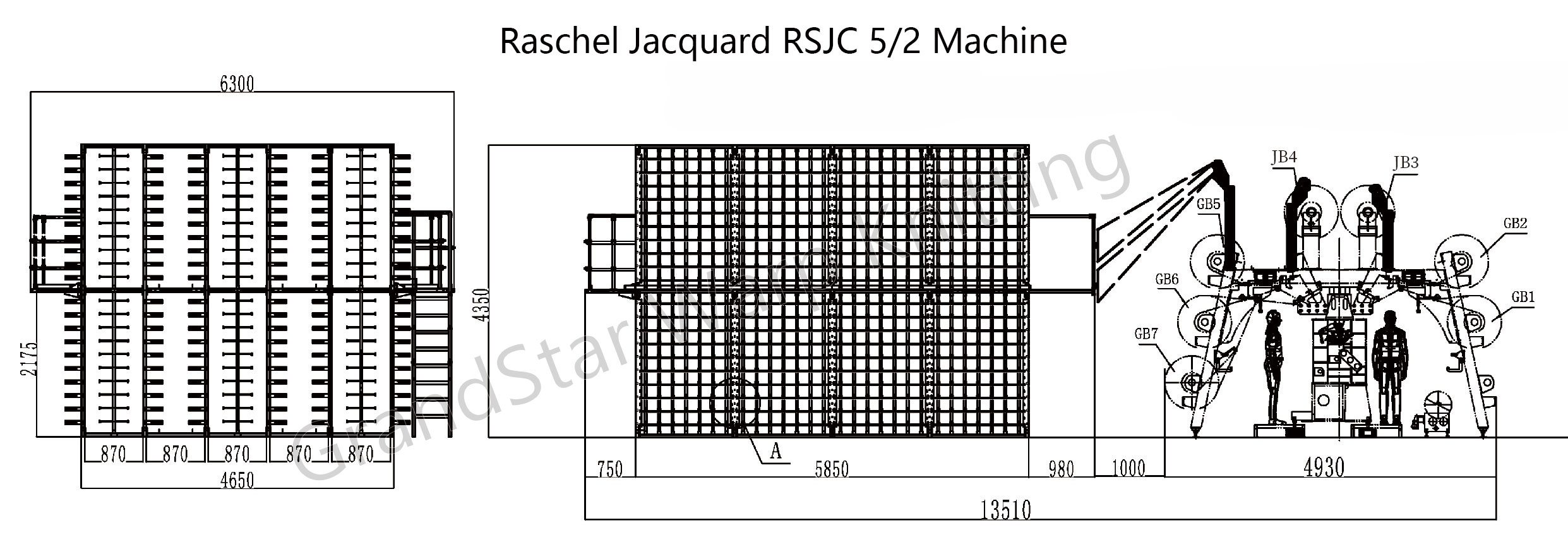

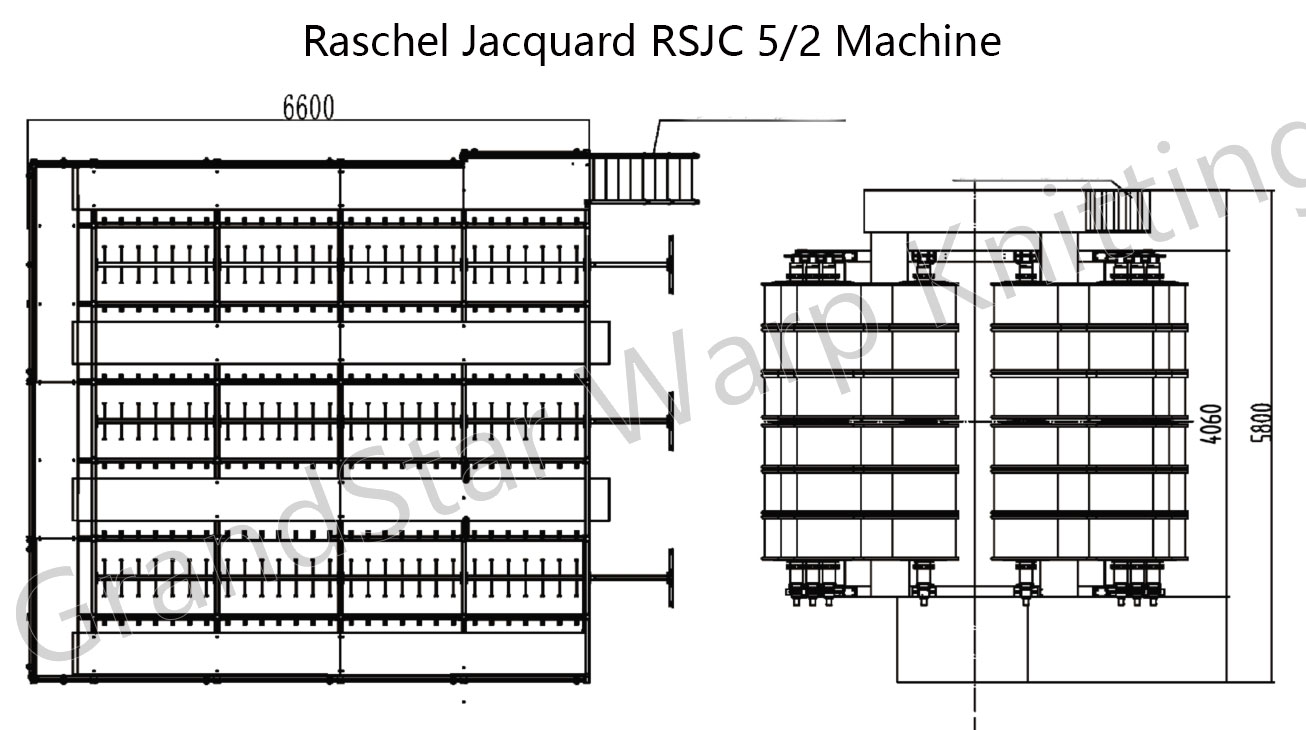

- TECHNICAL DRAWINGS

Working Width

3454mm (136 inches): Creates a vast working space for incorporating various technologies and accommodation that necessitate vast fabric manufacturing. It is available in E24 and E28 for fine and medium fabric gauge respectively.

Bars and Knitting Elements

- Individual Needle Bar and Tongue Bar: They serve a very important role of enhancing easy and accurate control of knitting mechanisms.

- The top combing section has a stitch comb bar, a knockover comb bar, and three ground guide bars and two group Jacquard bars (4 of them in total).

Warp Beam Support

This model can support six warp beam positions, particularly for sectional beams with flange dimension of 21 Inches and 32 Inches each.

Advanced Operator Interface

Equipped with the GrandStar® Command System; for on-demand configuration, control, and modulation of every electronic aspect.

Fabric Take-up and Batching Device

- With an electronically regulated fabric take-up system geared motor fitted with four rollers to support the fabric.

- Equipped with a second roller in order to accommodate a rolling diameter to up to 1270mm or 50 inches.

Pattern Drive

Equipped with an electronic guide bar drive (EL) for shogging up to 50mm, with options available up to 150mm in a 130” model.

Electrical and Oil Supply

- Electrical Equipment: 7.5 KW connected load, three phase, 380V ± 10%.

- Oil Supply: Heating and cooling through an air heat exchanger; a water conditioning system can be provided based on the nature of the environment in which it is installed.

Training & Service

Installation & Training

We offer technical training for warp knitting machines through videos, manuals, online tools, and on-site sessions in 20+ countries, supported by teams in five regions.

Local Service

Grandstar guarantees smooth machine performance through on-site services in Turkey, India, Vietnam, Indonesia, and the USA, supported by frequent inspections by skilled engineers.

Application

The RSJC 5/2 is ideal for producing a wide range of fabrics:

- Home Textiles: It involves curtain, upholstery and decorative fabrics.

- Fashion Fabrics: Thin and elaborate motifs for fabrics particularly used in designing clothing materials.

- Technical Textiles: Use of raw materials commonly found in industrial application in which stability is mandatory.

- Netting and Mesh Fabrics: Both for utilitarian and ornamental uses.

These beneath drawings give detailed instructions about the structure and functional parts of the machine to let it properly fit in your textile manufacturing plant.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |