Raschel Knitting Net Machine Latch Needle

| Single Raschel Netting Machine Latch Needle For Hay Bale Nets/Harvest Nets – Warp knitting Machine | |

| Model No. | GS-RN(X)-EN/EL |

| Ground Bars | 2/3/4/5/6/8 Bars |

| Gauge | E3/E6/E8/E10/E12/E18 |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

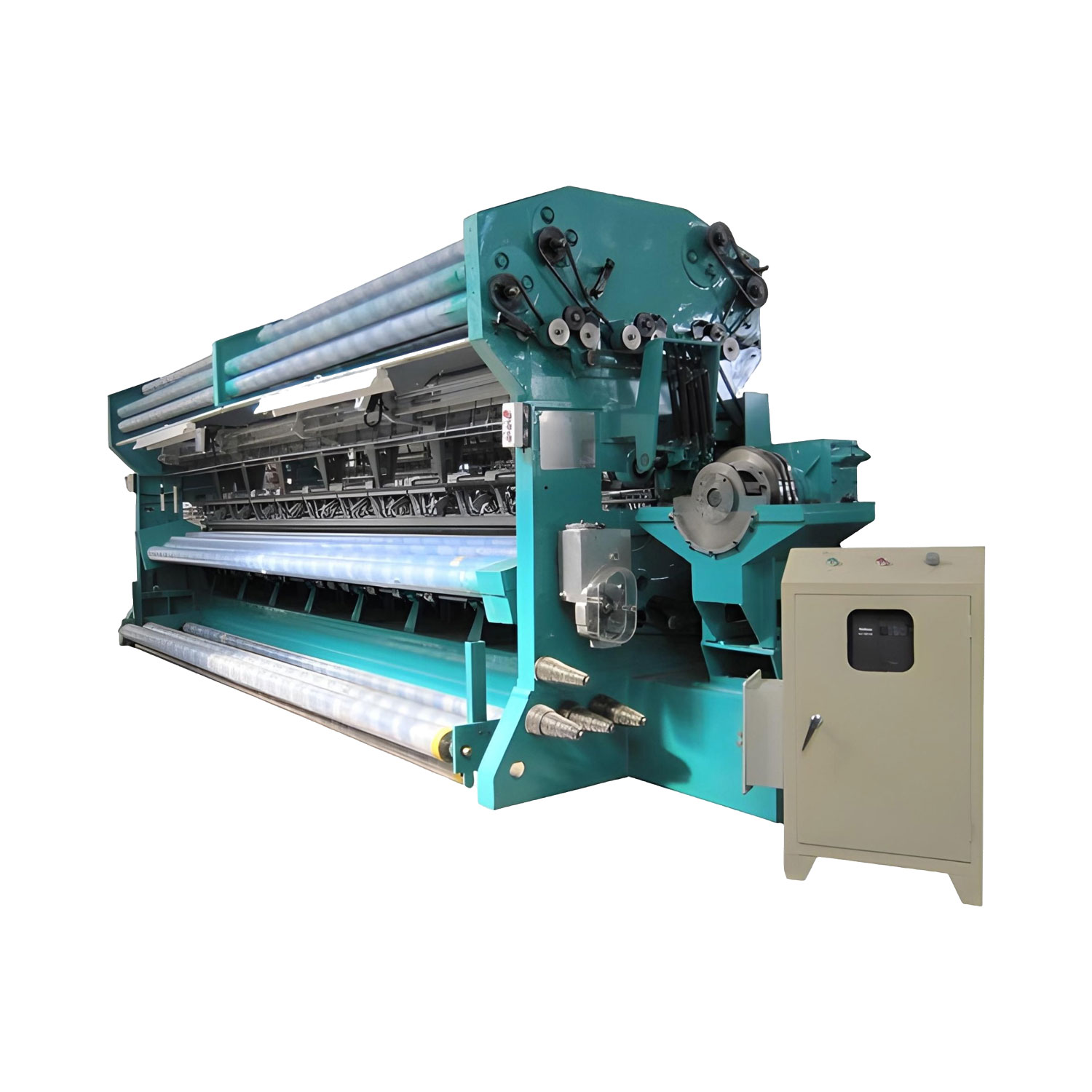

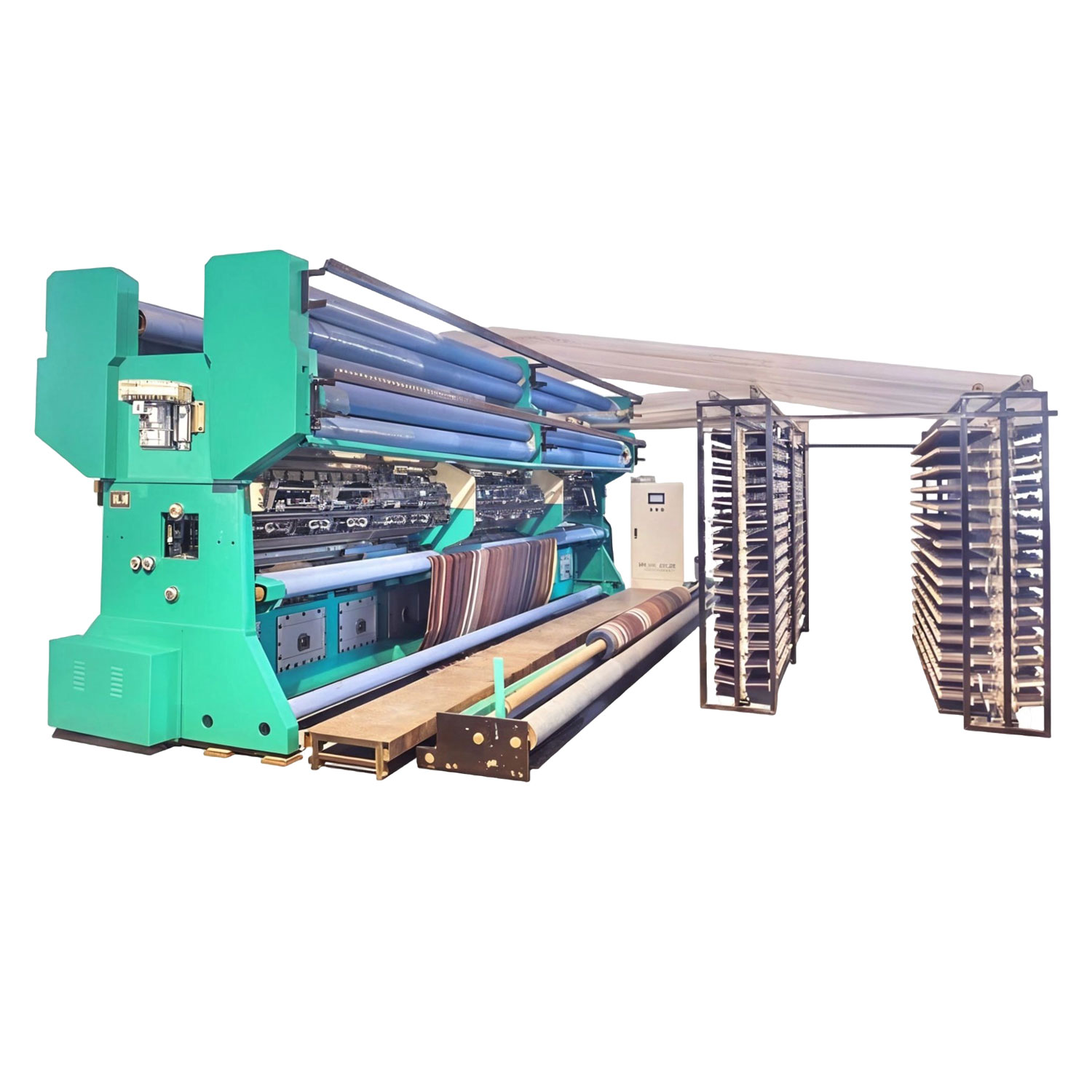

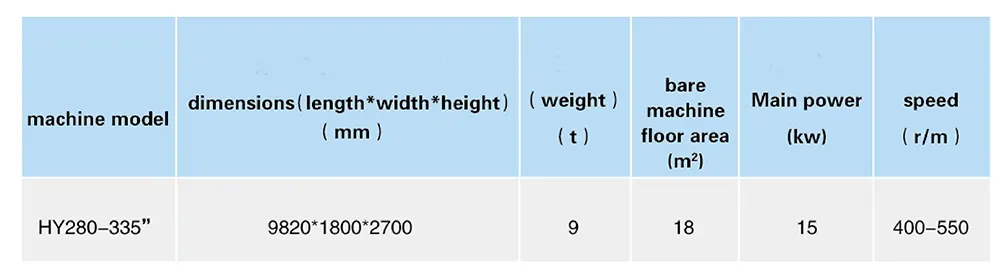

- TECHNICAL DATA

- TECHNICAL DRAWINGS

Working Width & Gauge

- Type: Latch needles (can be mounted on the bed in blocks or inserted separately)

- Gauge Options: E3, E6, E8, E10, E12, E18

- Widths Available: 181″, 205″, 268″, 283″, 335″, 413″, 503″

Knitting Elements

- Bars: Single-needle bar, knockover comb bar, slider bar, stitch comb bar

- Number of Bars: 6 (Options available: 2, 3, 4, 5, 6, 8)

Yarn Feeding Systems

-

Warp Beam Support:

- Supports 2/3/4/5/6/8 warp beam positions

- Free-standing for sectional beams with an 812 mm (32″) flange diameter

- Yarn let-off device: Electronically controlled, driven by a geared motor

-

Yarn Feeding Devices:

- 3 or 4 feeding device positions with 3 driven feeding rollers each

- Designed to work from a creel

-

FTL (Film Cutting and Stretching Device): For working with primary film

Control System

- User-friendly operator interface to configure, control, and adjust machine functionality

Integrated Monitoring Systems

- Integrated Laserstop: Ensures smooth and error-free operation

Fabric Take-up System

- Type: Mechanical regulated with friction drive

- Drive: Powered by a servomotor, controlled via Motion Control

Batching Device

- Type: Separate floor-standing cloth rolling device

Pattern Drive

- N-drive:

- Supports 2/3/4/5/6/8 pattern discs

- Integrated tempi change gear

Electrical Equipment

- Drive: Speed-regulated

- Total Connected Load: 25 kVA

- Voltage: 380V ±10%, three-phase power supply

- Power Cord Requirements:

- Main power cord: Minimum 4m², three-phase, four-core

- Ground wire: Minimum 6m²

Oil Supply

- System: None

Equipment Working Conditions

- Temperature: 25℃ ±6℃

- Humidity: 65% ±10%

- Floor Pressure: 2000–4000 KG/㎡

Training & Service

Installation & Training

We support warp knitting machines with training in 20+ countries, offering manuals, videos, online help, and on-site guidance with local teams in five major regions.

Local Service

With on-site support in Turkey, India, Vietnam, Indonesia, and the USA, Grandstar enhances machine performance through regular engineer-led inspections and upkeep.

Application

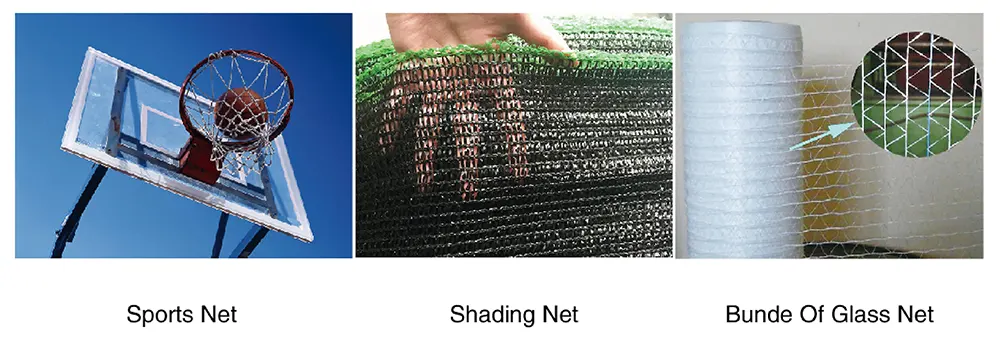

- Agriculture Nets: Used for shade nets, greenhouse covers, and anti-hail nets.

- Fishing Nets: Ideal for creating robust and durable fishing nets for commercial and recreational use.

- Sports Nets: Produces nets for tennis, soccer, volleyball, and other sports equipment.

- Packaging Nets: Suitable for crafting mesh bags and packaging solutions for fruits, vegetables, and industrial products.

- Safety Nets: Creates high-strength nets for construction safety, fall protection, and industrial use.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |