Fall Plate Raschel Lace Machine 84-Bars

| Fall plate Multibar Raschel Lace Machine – Warp Knitting Machine | |

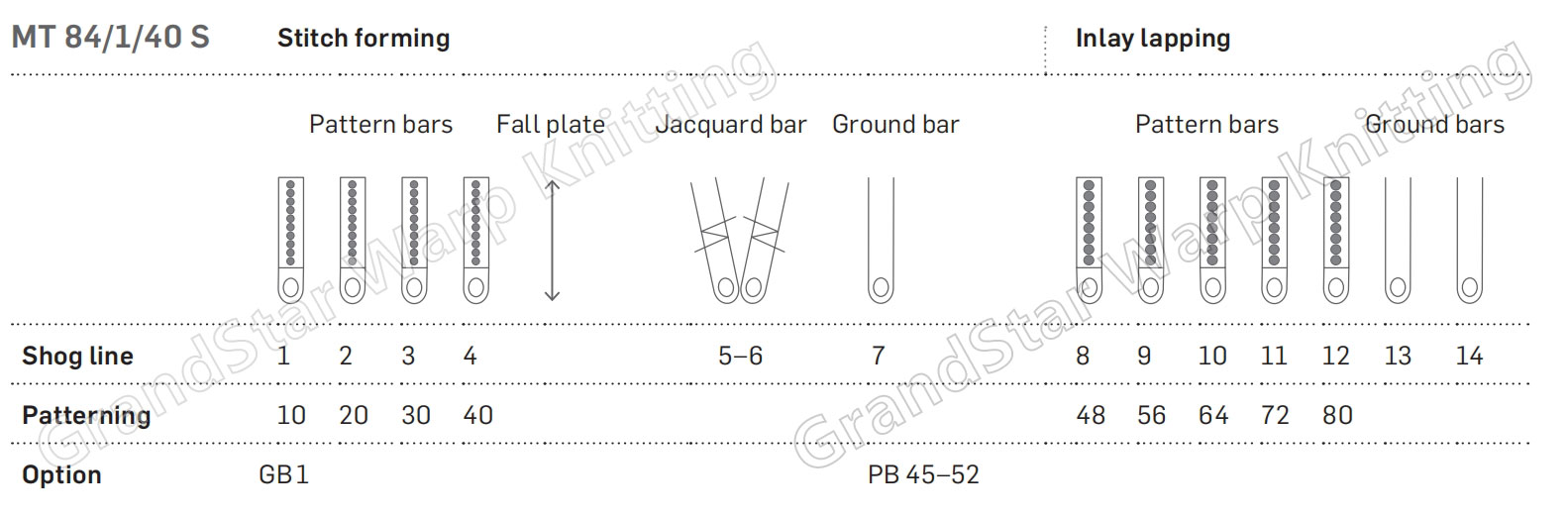

| Model No. | GS-MT 84/1/40 |

| Pattern Bars | 80 Bars |

| Ground Bars | 3 Bars |

| Jacquard Bars | 1 Bar |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

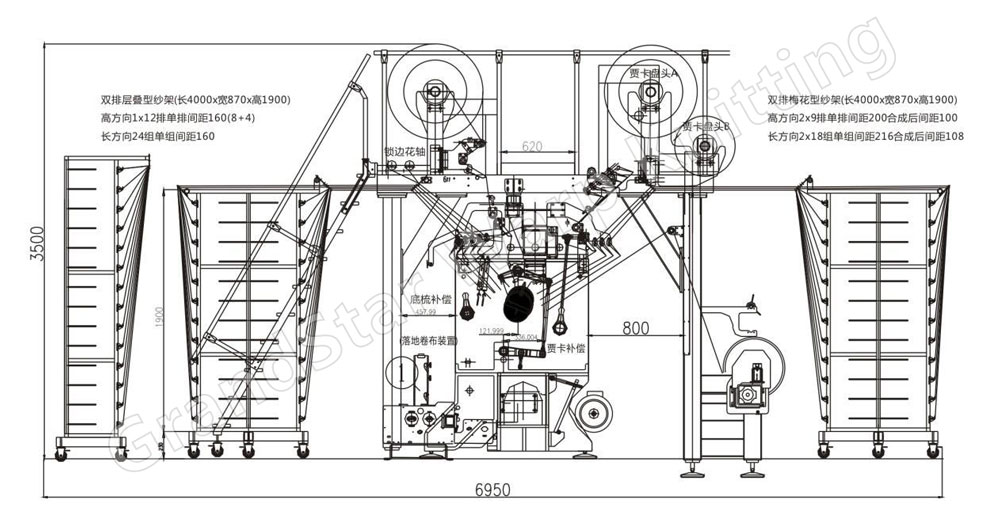

- TECHNICAL DRAWINGS

Engineered for Precision Elastic and Rigid Lace Production

Key Features

- Split Jacquard Bars for Precision Stitching

Includes two split Jacquard bars and one guide bar for accurate and efficient stitch formation.

- Rear Guide Bars with Counter-Lapping

Equipped with two rear guide bars, offering advanced pattern versatility and flexibility for intricate designs.

- PB2-11 System Replaceable with GB1

Seamlessly interchangeable for enhanced operational flexibility, adapting to various production demands.

- Multi-Functional Design

Tailored to meet diverse manufacturing requirements, enabling production of both elastic and rigid lace fabrics.

- Advanced Fabric Creation

Produces ultra-light, transparent, and durable ground fabrics, revolutionizing lace production.

- Innovative Warp Knitting Technology

Provides unparalleled performance and precision, setting new industry standards.

Technical Specifications

- Working Width:

3403 mm (134 inches)

- Gauge Options:

E24 / E28

Monitoring and Control Systems

- Integrated LaserStop Monitoring System

Ensures accurate operation and consistent monitoring.

- Yarn Let-Off System

Features four electronically controlled yarn let-off gears, offering superior tension control for both ground and Jacquard bars.

- Fabric Take-Up System

Electronically regulated fabric take-up driven by a geared motor with a four-roller mechanism for smooth, efficient fabric handling.

- Batching Device

Includes a separate floor-standing cloth rolling device for precise fabric batching.

Pattern Device EL

- Offers electronic control over guide bars for both ground and pattern bars, enabling intricate designs and consistent quality.

Electrical and Operational Requirements

- Drive System: Speed-regulated for consistent and precise operation.

- Power Requirements:

- Total connected load: 25 kVA

- Voltage: 380V ± 10% (three-phase power supply)

- Main power cord: Minimum 4 mm² (three-phase four-core power cord)

- Ground wire: Minimum 6 mm²

- Heat Management: Integrated oil/water heat exchanger for effective temperature control.

Operating Environment

- Temperature: 25°C ± 3°C

- Humidity: 65% ± 10%

- Floor Pressure: 2000–4000 kg/㎡

Training & Service

Installation & Training

Training for warp knitting machines is offered globally through videos, manuals, online guidance, and on-site programs, backed by local teams in Turkey, India, Vietnam, Indonesia, and the USA.

Local Service

Grandstar ensures machine longevity with on-site services across Turkey, India, Vietnam, Indonesia, and the USA, combined with professional maintenance routines.

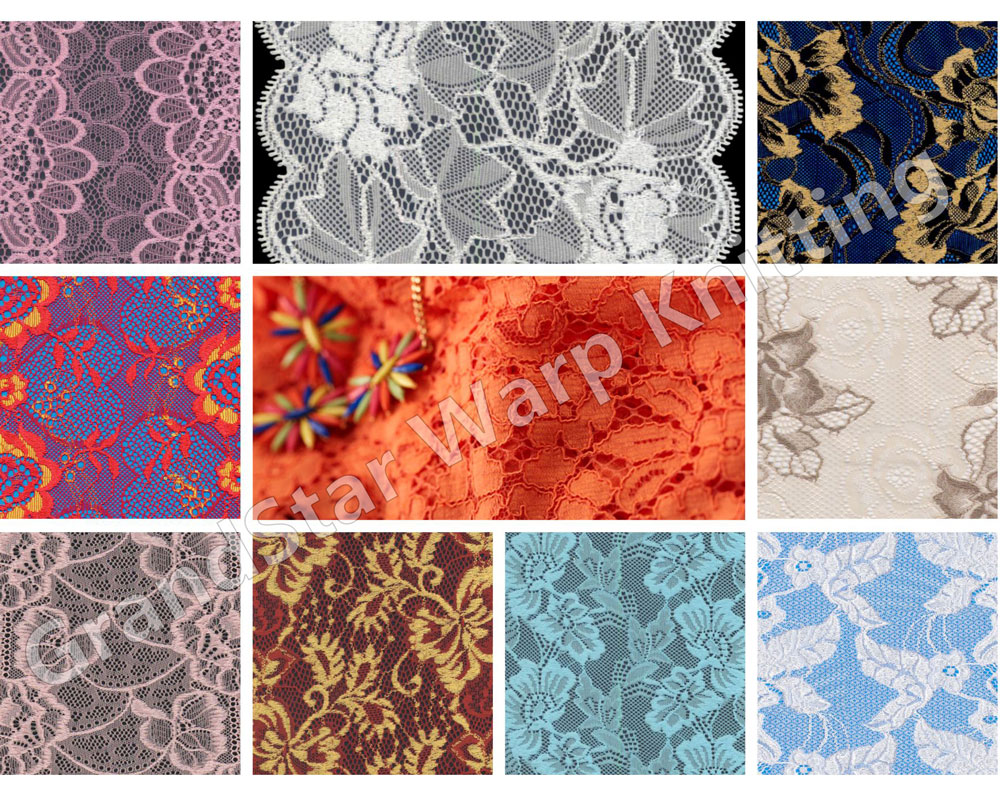

Application

-

Elastic and Rigid Lace Fabric Production: Ideal for producing intricate lace patterns for fashion apparel, lingerie, and accessories.

-

Home Décor and Upholstery: Enables the creation of decorative lace fabrics for curtains, cushion covers, and tablecloths.

-

Technical Textiles: Produces durable and lightweight lace for specialty applications, including medical textiles and industrial design.

-

Transparent Ground Fabrics: Creates ultra-light, transparent ground fabrics for advanced design applications in both fashion and interiors.

-

Customized Lace Patterns

- Offers unparalleled pattern versatility to meet the needs of high-end design and industrial applications.