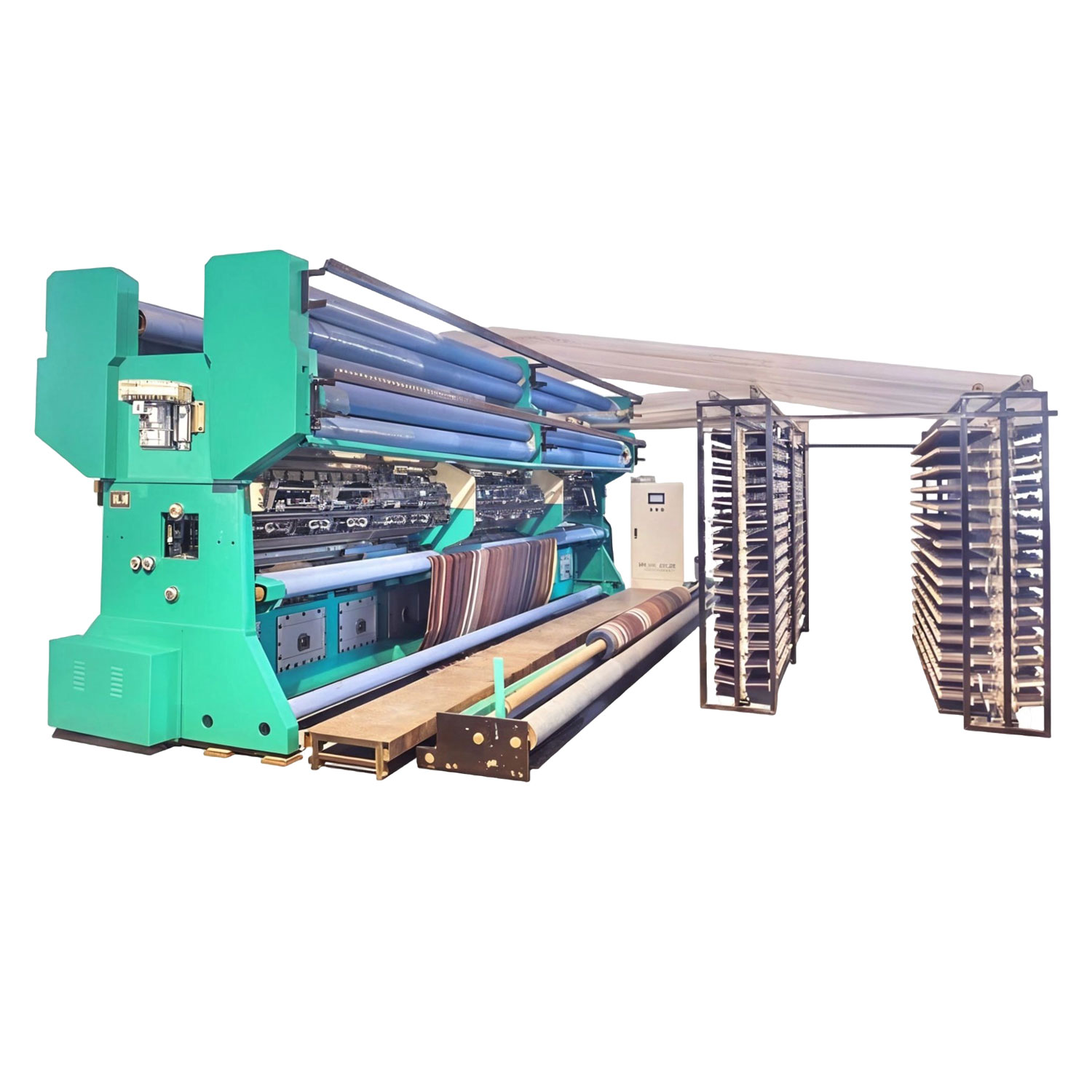

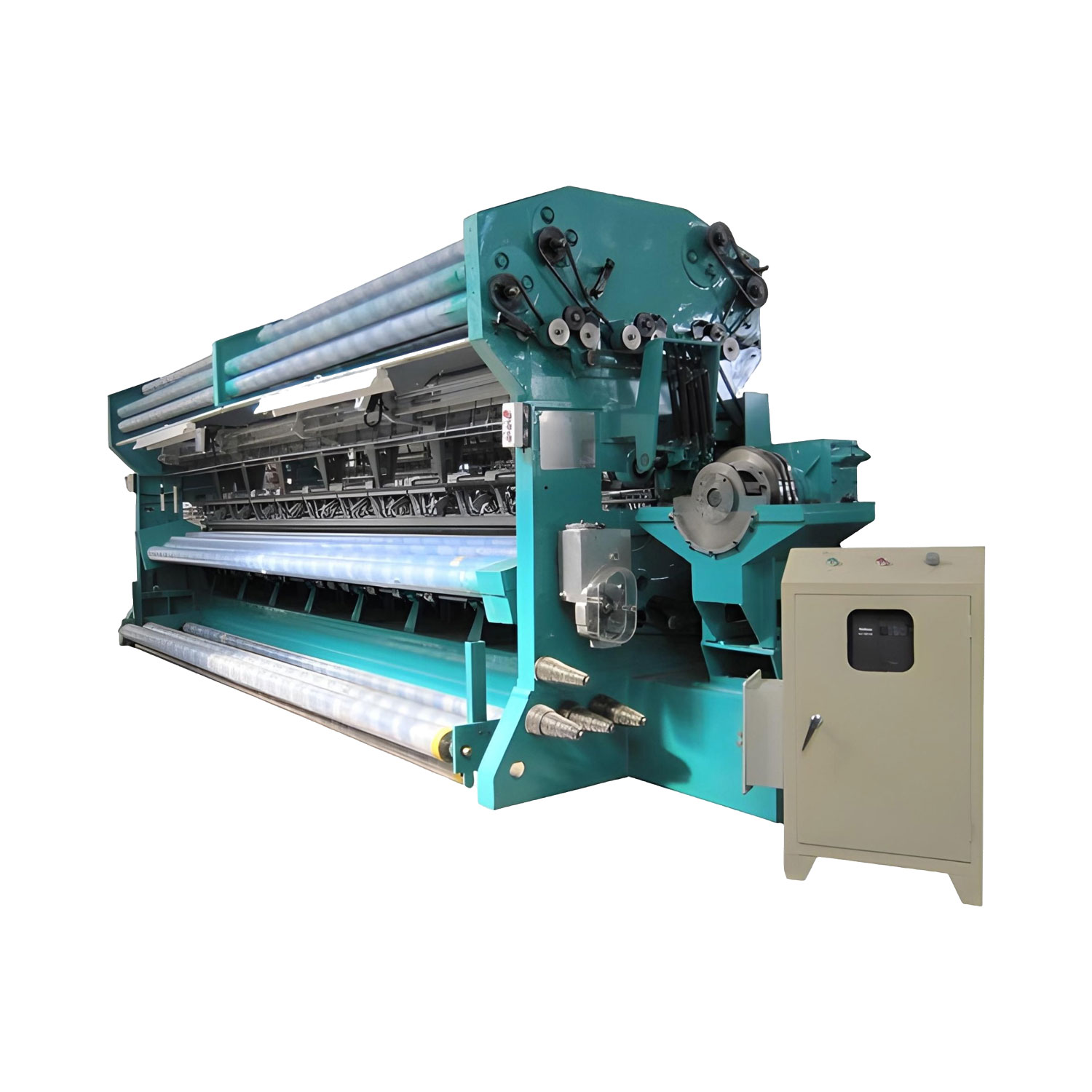

Raschel Netting Machine 2-8 Bars

| Single Raschel Netting Machine For Fishing Nets/Anti-Bird Nets – Warp knitting Machine | |

| Model No. | GS-RS(X)-EN/EL |

| Ground Bars | 2/3/4/6/8 Bars |

| Gauge | E6/E8/E12/E18 |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

- TECHNICAL DRAWINGS

Working Width & Gauge:

- Type: Compound needles

- Gauge: E6, E8, E12, E18

- Width: 181″, 188″, 220″, 230″, 275″

- Bars / Knitting Elements:

- Single-bar bar, knockover-cum-comb bar, and slider bar.

- Stitch comb bar

- 2/3/4/6/8 ground guide bars or 2 pattern bars with 4 ground guide bars.

- GB1 to GB4 stitch-forming

Yarn Feeding Systems:

- WARP BEAM SUPPORT

- Position: 4 warp beam positions, free standing arrangements warped from sectional beams with flange diameter 812mm x 32”.

Yarn let-off device is electronically controlled by the means of a geared motor.

GrandStar® (GrandStar COMMAND SYSTEM):

- A system where by an operator is able to set or program, manage and modify the electronic characteristics of the machine.

Integrated Monitoring Systems:

Integrated Laserstop

Yarn Let-off Device:

For each completely mounted warp beam position, One electronically controlled yarn let-off drive is another.

Fabric Take-up:

Electronically regulated system with an antifriction drive; gearing is driven by a servomotor and regulated by Motion Control.

Batching Device:

Cloth rolling device which is treated as a floor-standing equipment.

Pattern Drive:

Electronics guide bar drive EL.

Electrical Equipment:

- Speed-regulated drive

- Total connected load of the machine: 25 kVA

- Voltage: Power supply specifications require 380V±10% three phase power.

- Main power cord requirements: No less than 4mm² three-phase four-core power cord, ground wire no less than 6mm²

- Oil Supply: Oil/water heat xchanger

Equipment Working Conditions:

Temperature: 25℃±6℃

Humidity: 65%±10%

Floor pressure: 2000-4000KG/㎡

Training & Service

Installation & Training

With training in 20+ countries and local teams in Turkey, India, Vietnam, Indonesia, and the USA, we offer comprehensive support through videos, manuals, online help, and on-site sessions.

Local Service

To ensure peak performance, Grandstar offers on-site services in key regions like Turkey, India, Vietnam, Indonesia, and the USA, paired with regular inspections by skilled engineers.

Application

Applications of Raschel Netting Machines

Raschel netting machines are essential in industries that require high-quality, durable, and versatile netting solutions. These machines operate using a warp knitting technique to produce various types of nets with different mesh sizes and densities. Below are the primary applications of Raschel netting machines:

-

Agricultural Sector:

Raschel netting machines produce protective nets for crops, trees, and greenhouses. These nets are designed to shield plants from harsh weather, pests, and birds, enhancing agricultural productivity. -

Fishing Industry:

The fishing industry heavily relies on Raschel netting machines to produce durable, knotless nets. These nets are used in commercial fishing, aquaculture, and even for recreational purposes. -

Sports and Recreation:

Nets for sports such as soccer, volleyball, and tennis are also crafted using Raschel netting machines. The machines allow customization of net dimensions, strength, and elasticity, meeting the specific requirements of different sports. -

Industrial Uses:

Industries use nets for safety purposes, such as fall protection and load securing. Raschel machines are instrumental in producing nets that are strong yet lightweight, catering to various industrial safety standards.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |