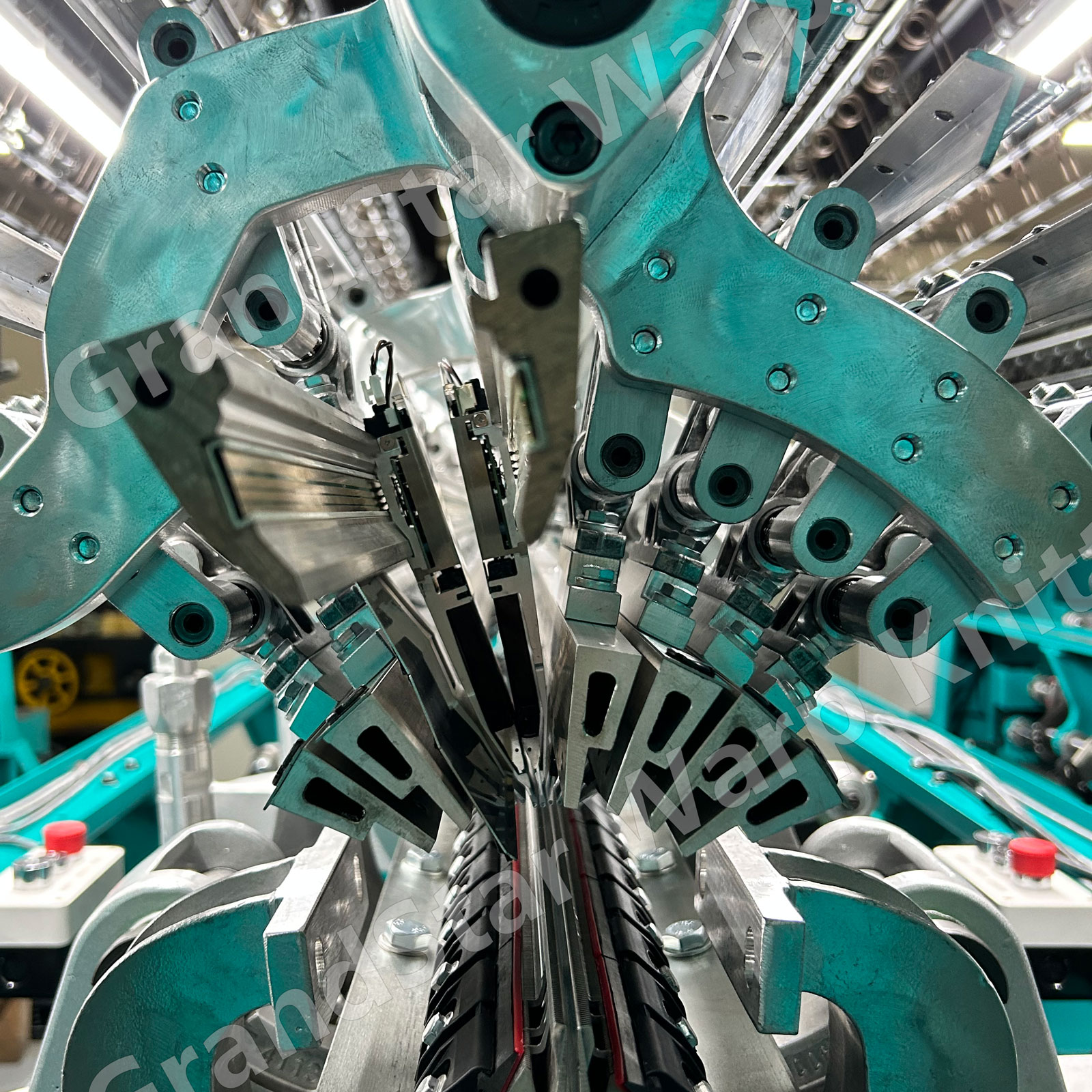

Recondition Machine

| Category | Solutions |

| Place of Origin | Fujian,China (Mainland) |

| Certification | CE |

| Package | Wooden Cases |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

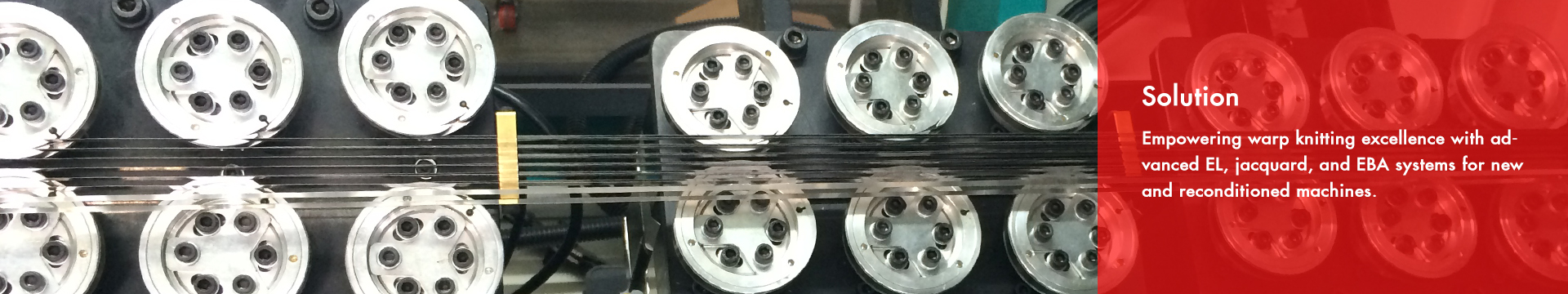

- PRODUCT DETAILS

- Regular inspection and testing

Each and every machine is looked after carefully so that they are in the best possible working condition, especially built tough.

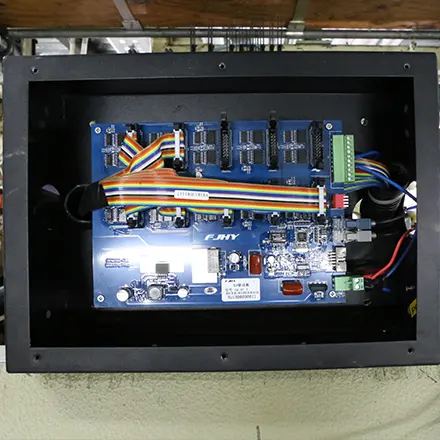

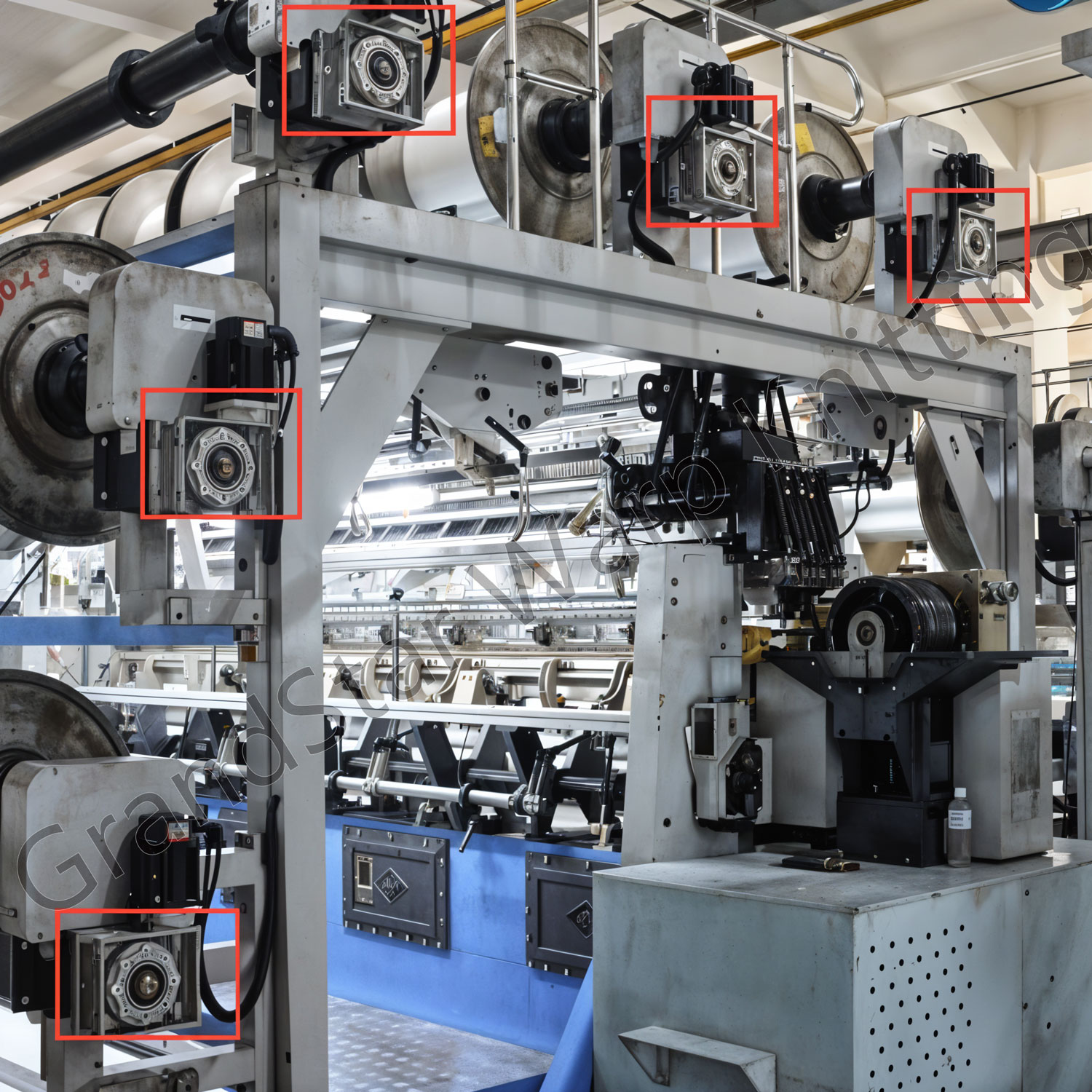

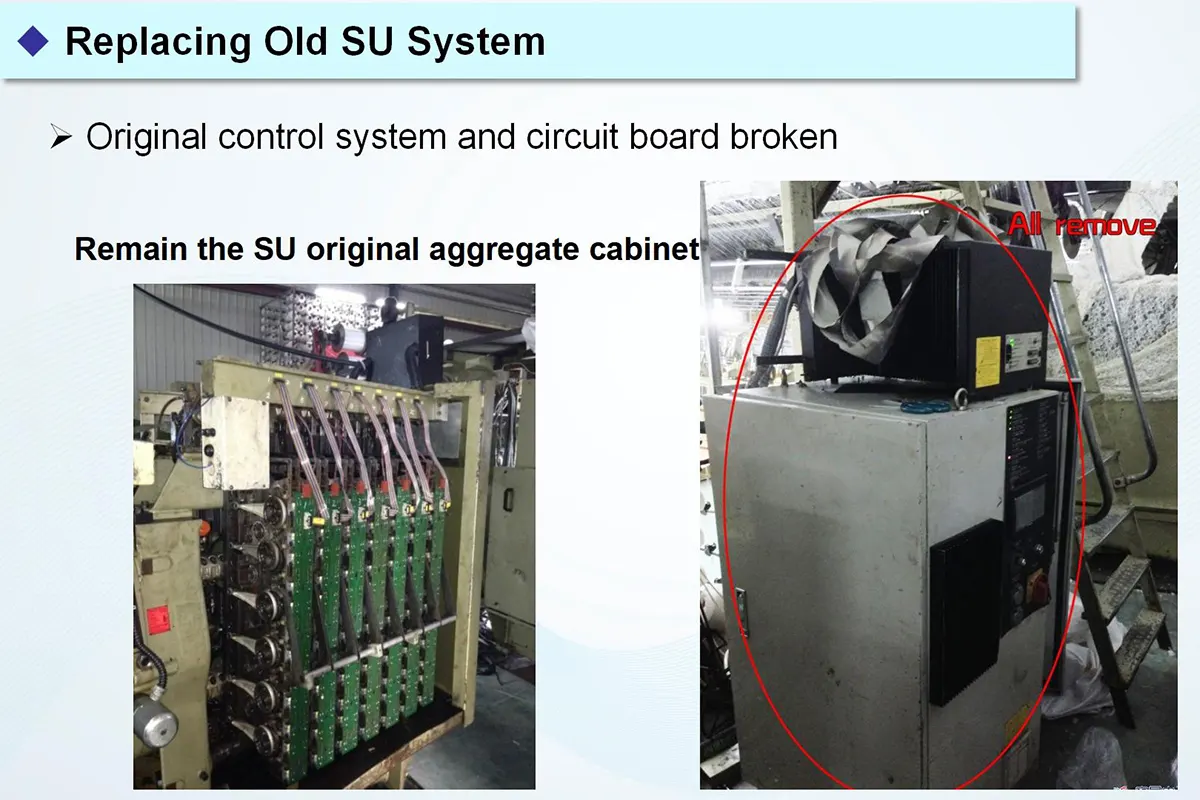

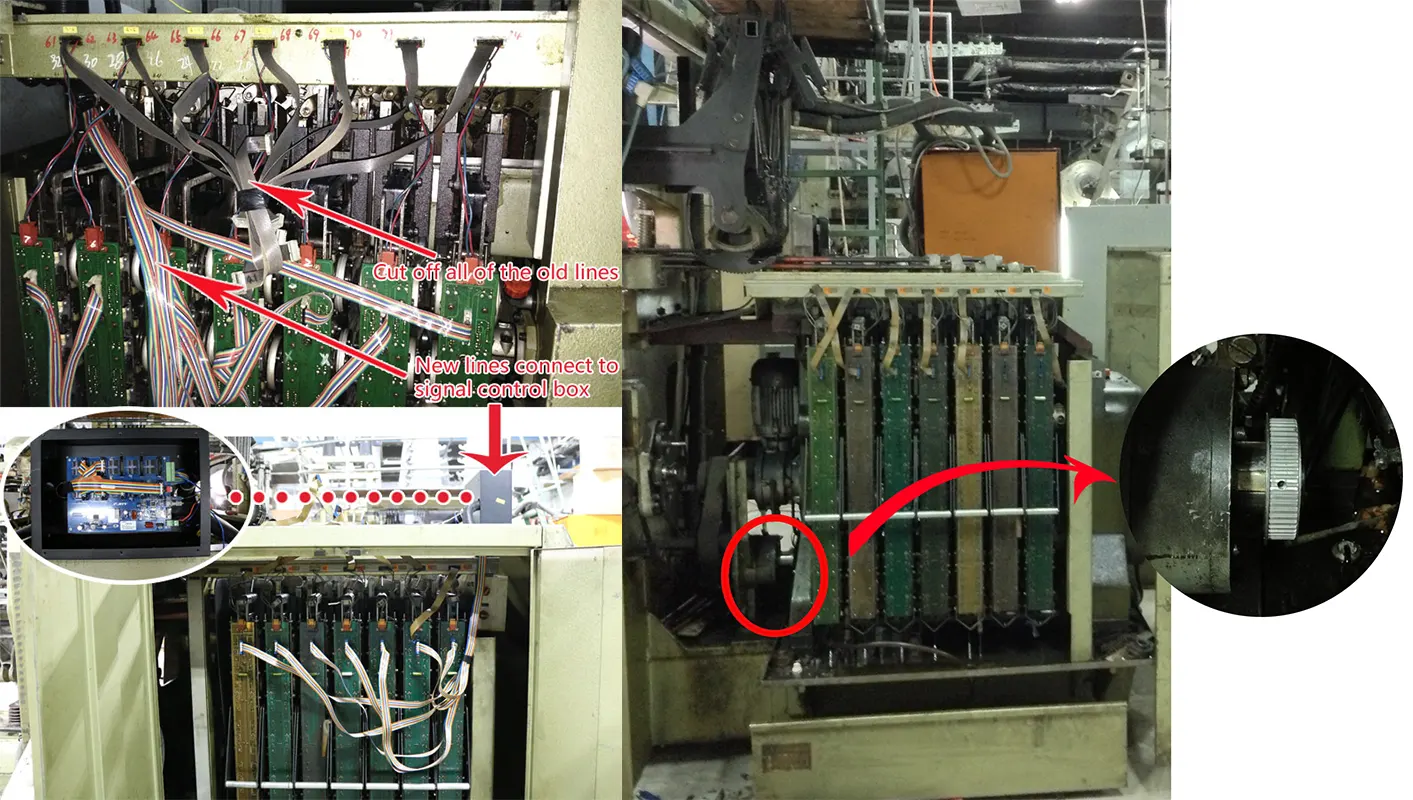

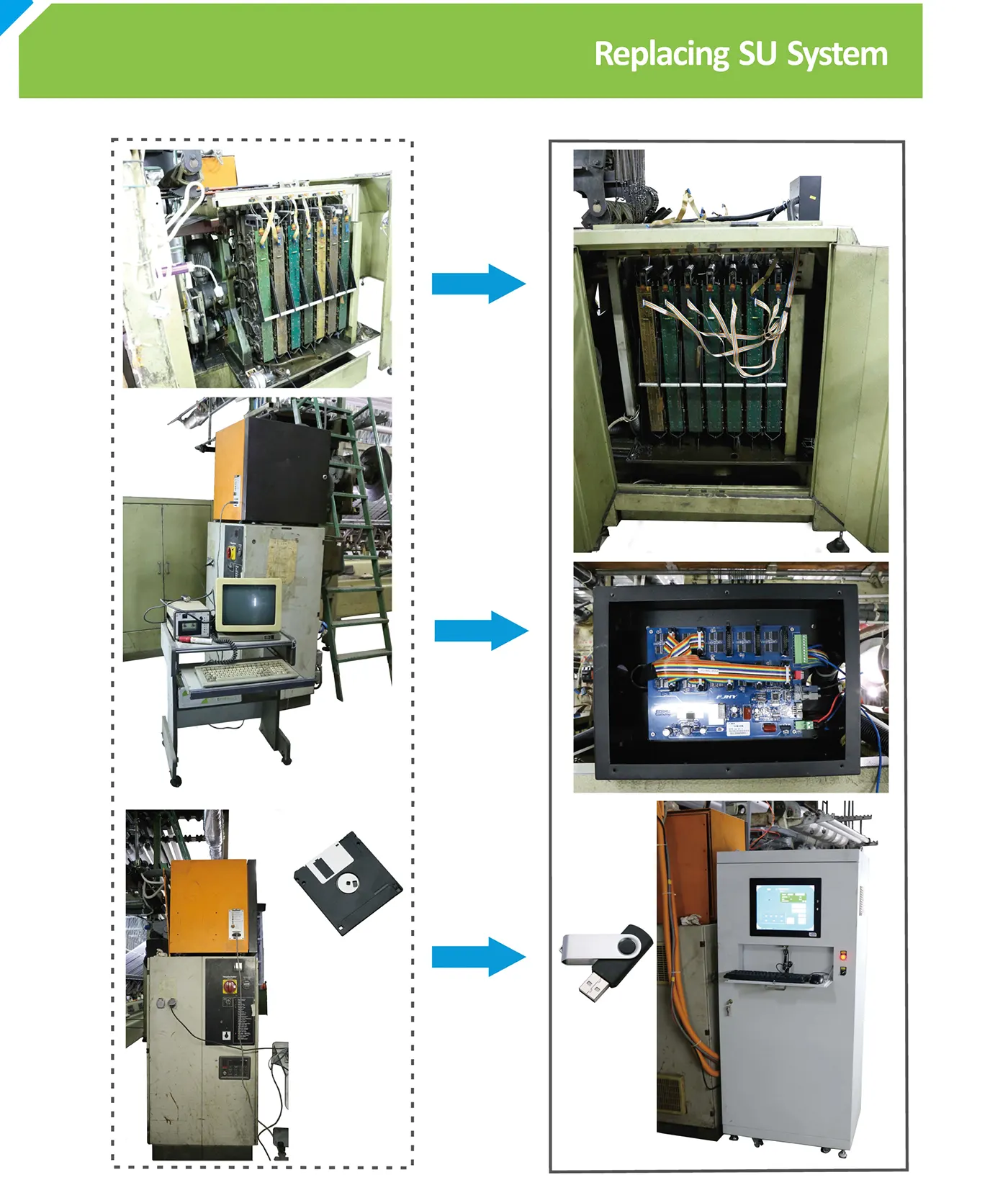

- Upgraded Components

Faulty or outmoded parts are substituted by new, high quality components so that the efficiency of the item increases.

- Enhanced Performance

These machines undergo readjustment in order to achieve the necessary parameters intending to match the requirements of contemporary production conditions.

- Cost-Effective Solution

Produce the capabilities of new equipment at a much lower price.

- Customizable Upgrades

One can get customized refurbishments as per the requirement for the production line either in electronics or structural changes.

- Sustainability

Encourages environmental conservation since it achieves the reestablishment of the lifecycle of industrial implements rather than the frequent disposal of substandard products.

Application

- Automotive Manufacturing

Saves money when used to manufacture automotive textiles or even automotive textile parts since it will deliver quality work without the need to acquire new equipment.

- Home Furnishings

Used in the manufacturing of curtains, upholstery and decorative and fashion fabrics with ease and accuracy.

- Industrial Applications

Used machines can be reused for technical purposes like medical textiles, filtration fabrics and protective wears.

- Small and Medium Businesses

Caters for those small businesses that wish to expand capacity without necessarily buying new equipments.