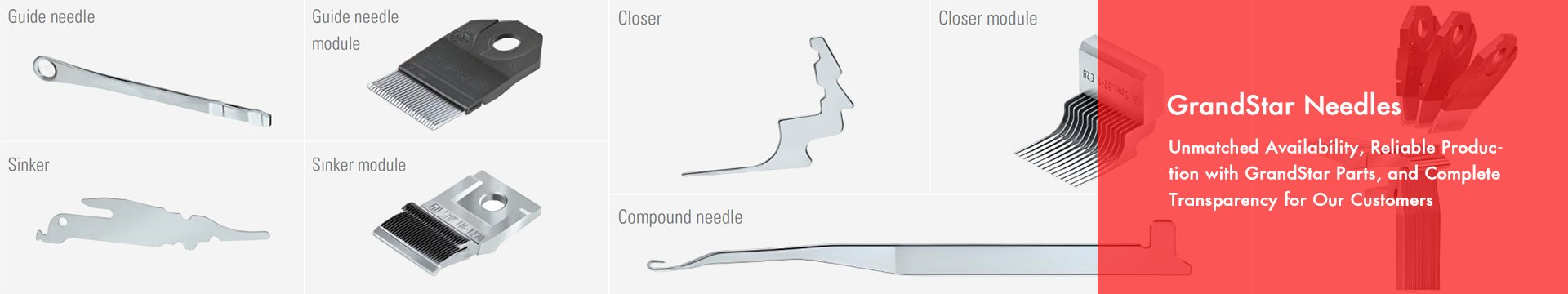

Sinker Needle

| Sinker Needle (Sinker Module) For Warp Knitting Machine | |

| Model No. | P-XX-XX |

| Place of Origin | Fujian, China |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- PRODUCT LIST

Sinker Needle (Sinker Module) for Warp Knitting Machines

Introduction to Sinker Modules

Sinker modules are essential components in warp knitting machines, designed to meet the diverse requirements of various machine types. These modules play a pivotal role in fabric production, with their design and functionality tailored to specific machine applications.

For high-speed tricot machines, combined holding-down and knockover sinker modules are predominantly used. These modules excel in maintaining precision, which is critical for achieving high-quality fabric. In contrast, Raschel machines utilize a wider variety of sinker modules, many of which serve supporting or holding functions during loop formation. While these modules are vital for operational stability, their direct impact on fabric quality is generally less significant compared to holding-down and knockover sinker modules.

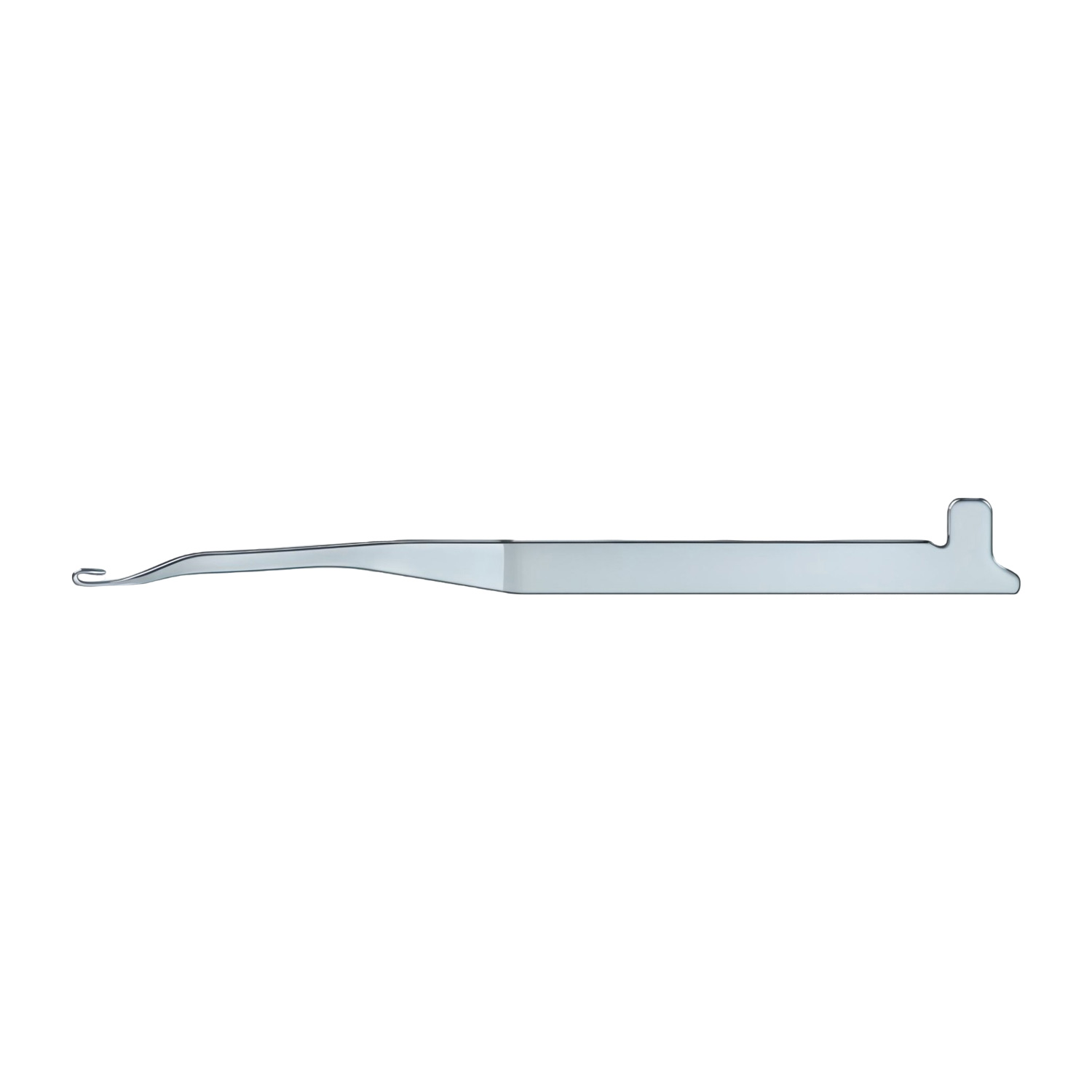

Functions of the Sinker Needle

The sinker needle in high-speed warp knitting machines is responsible for:

- Holding and Controlling Coils: It secures and guides the old coils while assisting in the winding process.

- Adjusting Yarn Bending Depth: By moving up and down, the distance between the settlement piece and the sinker needle can be adjusted to set the depth of the yarn’s bending arc.

- Fine-Tuning Coil Density and Length: Forward and backward adjustments of the settlement sheet help ensure the optimal distance between the throat and the groove needle rod, enabling precise control over coil density and stem length.

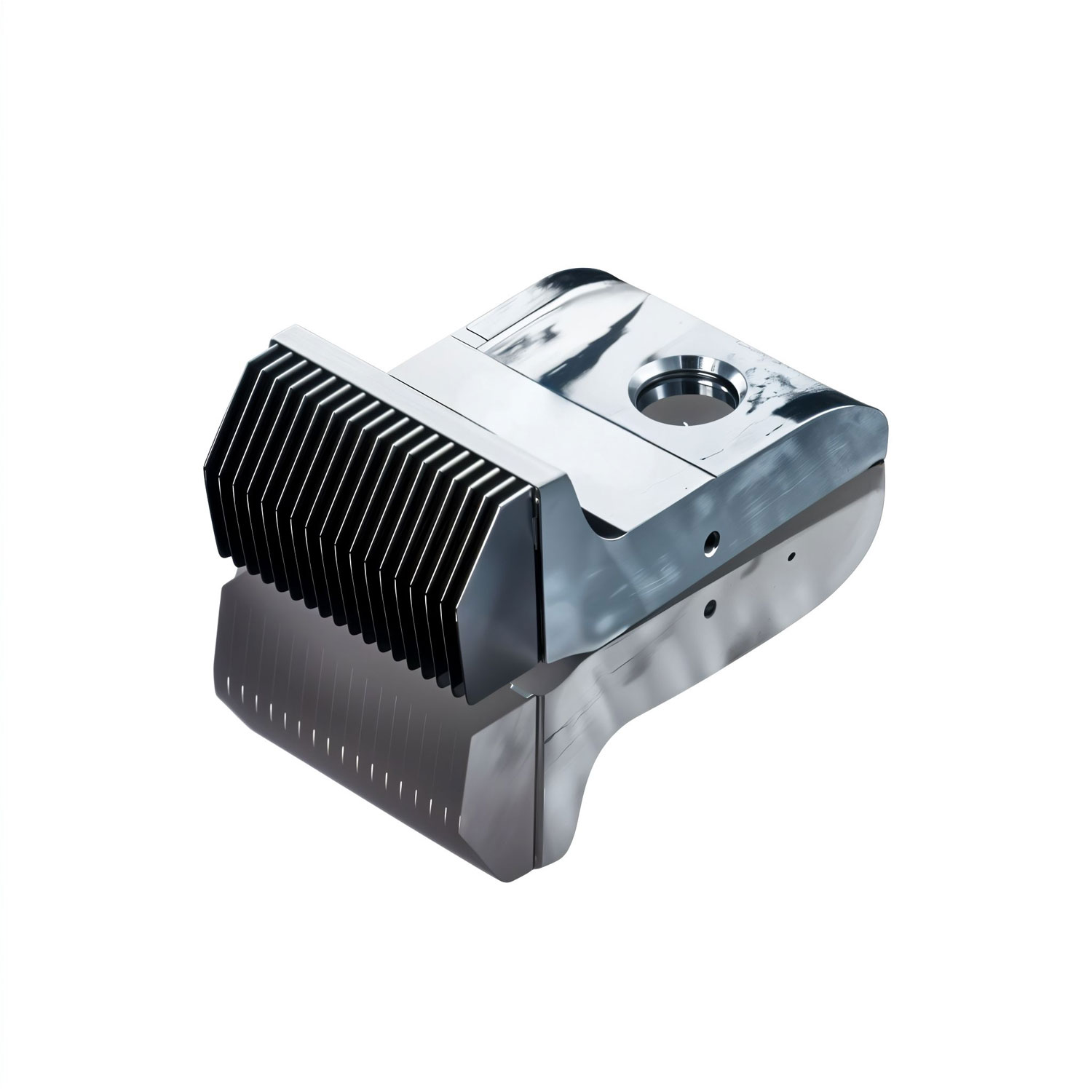

Settlement Sheet in Raschel Warp Knitting Machines

The settlement sheet is a critical component specifically designed for Raschel warp knitting machines. Its key features include:

Material Composition

Manufactured using high-grade stainless steel and tin block, ensuring durability and resistance to wear.

Design Details

The front end of the alloy sheet is equipped with multiple grooves that accommodate yarn guide needles. Each groove precisely aligns with a corresponding yarn guide needle, enhancing operational accuracy.

Importance of Precision and Material Selection

The precision of sinker modules significantly influences the quality of fabric produced, particularly in high-speed tricot machines. Similarly, the choice of materials, such as stainless steel and alloys, ensures long-lasting performance and consistent results in demanding industrial applications.

Why Choose Our Sinker Modules?

At GrandStar Warp Knitting Company, we understand the importance of high-performance sinker modules. Our products are engineered with meticulous attention to detail, combining cutting-edge technology with robust materials to meet the highest standards of precision and efficiency.

By integrating our sinker modules into your warp knitting machines, you can achieve superior fabric quality, operational reliability, and enhanced productivity—making them the ideal choice for professional textile manufacturers.