Split warping Machine

| Split Warping Machine / Warp Preparation | |

| Model No. | GS-DSS 21-30 / 21-30 |

| Application | Filament Yarn |

| Beam Size | Max 21*30″ |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

Split Warping Machine: Precision, Efficiency, and Innovation

The Split Warping Machine is an advanced, high-performance solution developed to meet the increasing market demands for high-speed, high-density warp knitting, as well as for processing superfine, high-stretch filaments, specialty fibers, and value-added textile products. Engineered with our company’s patented technology and incorporating the latest international advancements, this machine sets a new benchmark in the warp knitting industry.

Versatile Applications & Superior Performance

Designed as a multi-functional system, the Split Warping Machine is adaptable to a wide range of yarn types, including:

- Chemical fiber filaments

- Low-stretch yarns

- Acrylic and cotton spun yarns

- Single filament processing

Its cutting-edge technology ensures exceptional performance, making it the ideal choice for high-speed warp knitting applications.

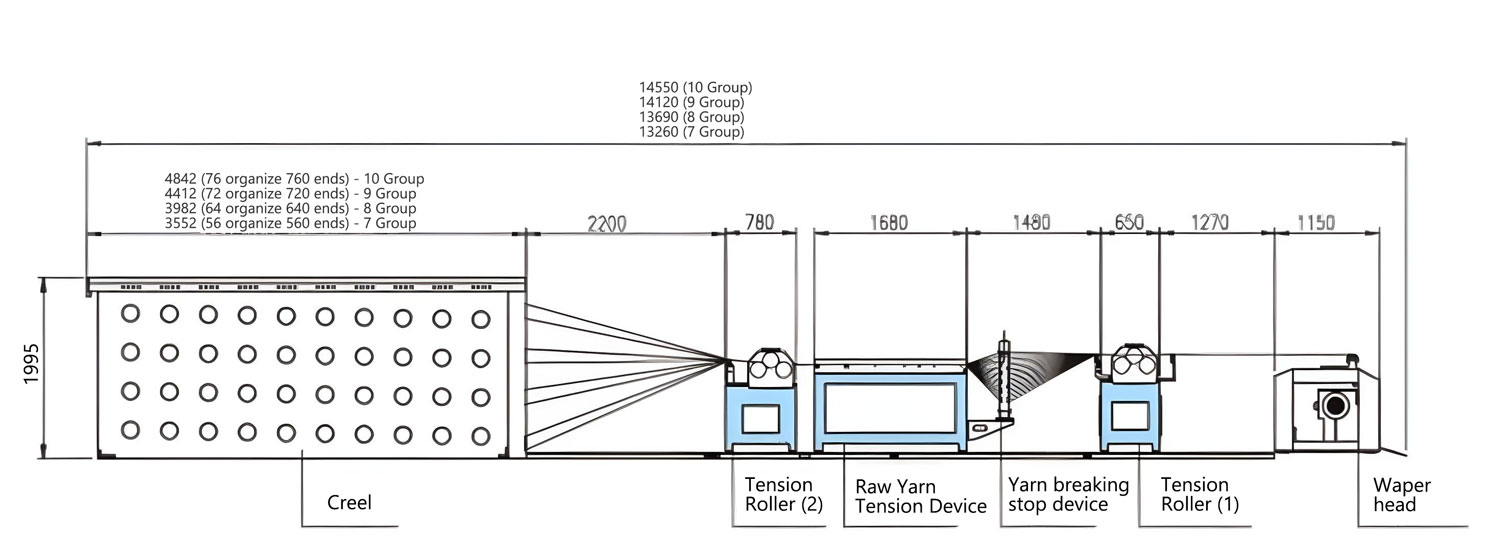

Innovative Mother Yarn Splitting & Direct Warping

This machine excels in splitting mother yarn and directly winding it onto a warp beam in a single, streamlined process. Whether processing nylon, polyester, or other mother yarn types, the integrated splitting and warping function significantly enhances efficiency, precision, and cost-effectiveness by:

- Eliminating the need for separate splitting and warping processes

- Reducing production time and space requirements

- Lowering operational costs

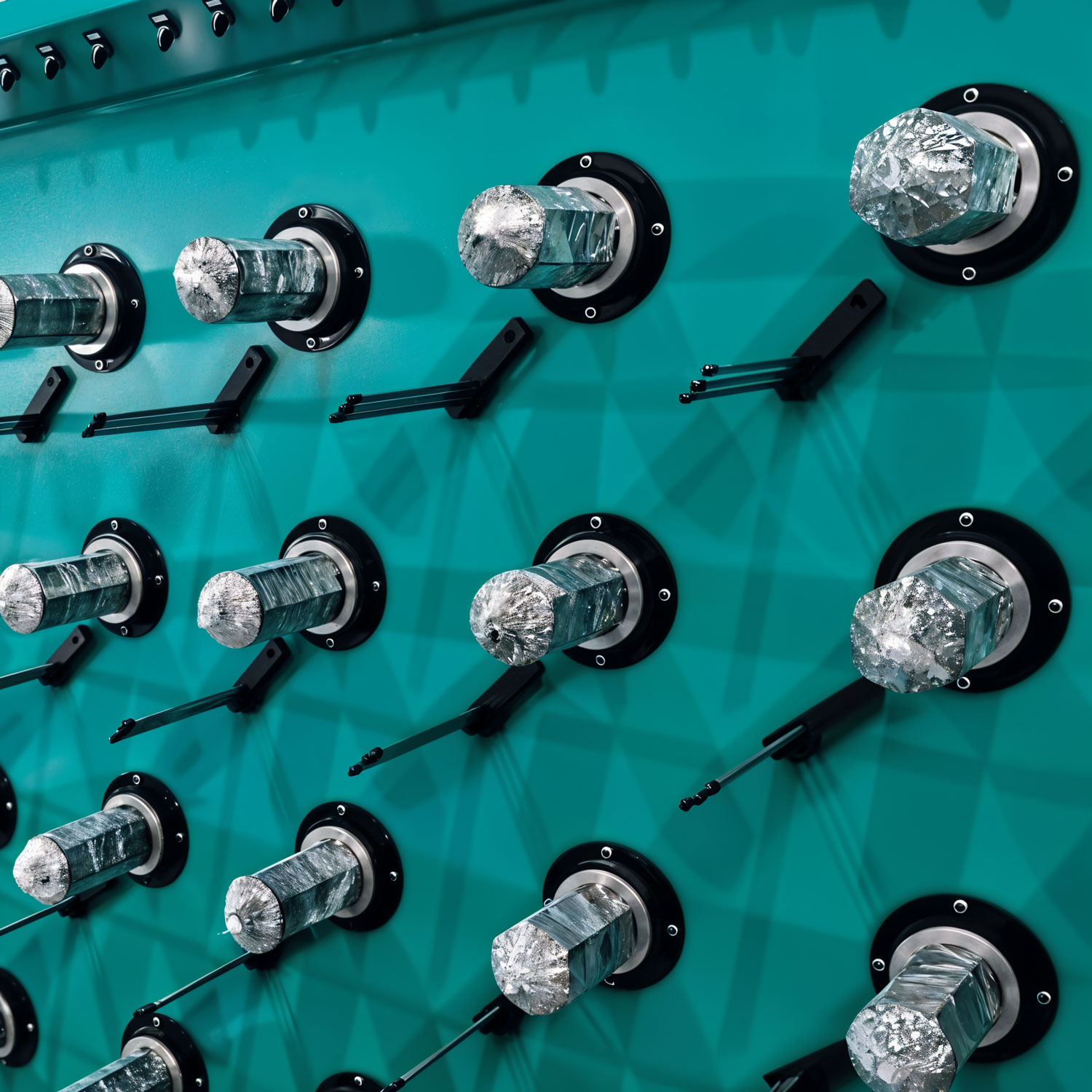

Advanced Tension Control for Flawless Warping

Equipped with a specialized tension roller system and a high-precision individual electric creel tension motor, this machine guarantees:

- Equal winding tension across all yarns

- Seamless continuous operation with minimal yarn breakage

- Enhanced warp knitting quality and consistency

State-of-the-Art Automation for Maximum Efficiency

The automatic tension control system, powered by a customized, next-generation PLC touchscreen interface, ensures:

- 100% utilization of cheese yarns with little to no waste

- Optimized yarn consumption, reducing material loss

- Superior process automation, minimizing manual intervention

Your Best Choice for High-Speed Warp Knitting

With its unparalleled technological advancements, high-speed capabilities, and versatile yarn adaptability, the Split Warping Machine is the ultimate solution for modern warp knitting manufacturers seeking to enhance production efficiency, reduce costs, and achieve superior fabric quality.

Training & Service

Installation & Training

Our technical support covers warp knitting machine training via manuals, videos, online resources, and on-site programs in over 20 countries, with teams in five key regions.

Local Service

Grandstar ensures machine longevity with on-site services across Turkey, India, Vietnam, Indonesia, and the USA, combined with professional maintenance routines.

Application

- Filament Yarn Processing:

This machine is perfect for direct warping of filament yarns, including synthetic, polyester, and nylon yarns, ensuring precise tension and consistent quality. - High-Tenacity Yarn Warping:

With its high-tenacity device, it can handle yarns with up to 1600N tension, making it suitable for heavy-duty textile applications such as industrial fabrics and technical textiles. - Textile Weaving Preparation:

It prepares warp beams efficiently for weaving operations, offering uniform tension and alignment critical for high-quality fabric production. - Specialty Fabrics Production:

The tandem warping device allows for processing specialty yarns, enabling the production of customized fabrics for industries such as automotive, aerospace, and home furnishings.

GS-DS Series Technical Specifications

| Feature | GS-DS 21/30 DNC | GS-DS 21/40 DNC |

|---|---|---|

| Maximum Speed | 1000 m/min. | 1000 m/min. |

| Maximum Yarn Tension | 200N | 200N |

| Pressure Roller | Available | Available |

| Levelling Roller Unit | Yes | Yes |

| Tandem Warping Device | Available | Available |

| High-Tenacity Device | Available | Available |

| Maximum Yarn Tension (High-Tenacity) | 1600N | 1600N |

| Maximum Speed (High-Tenacity) | 600 m/min. | 600 m/min. |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |