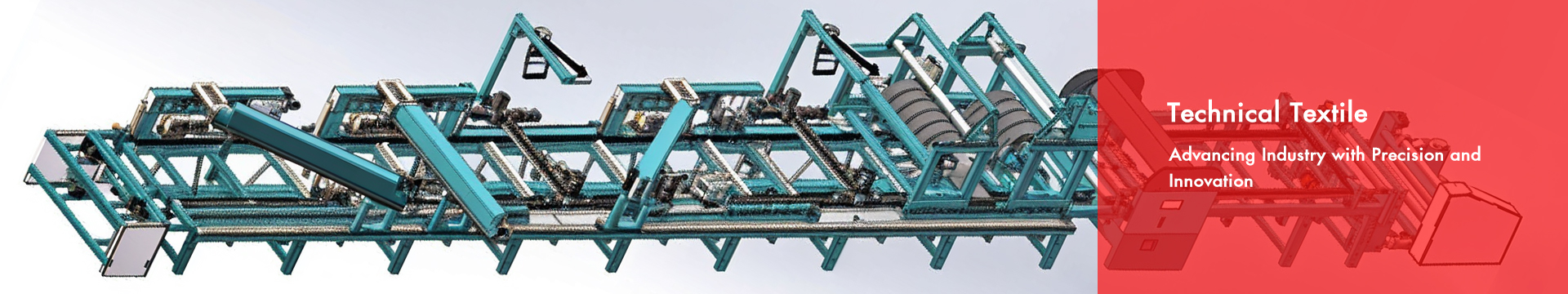

Technical Textile

Technical textile machines are special purpose and sophisticated equipment used for producing technically premium fabrics with desired performances. These machines form the basics of producing the fabrics much as the ones not for aesthetic and general functional purposes but as ones developed to serve particular needs in various industries. Modern technical textile machines can produce fabrics of high performances like geotextiles, medical textiles, protectant cloths and industrial composites. Developing these machines are accurate, fast and flexible since the world is more demanding for textile solutions.

Key Features of Technical Textile machine

- Precision Engineering: Sophisticated instruments and automated processes guarantee the creation of fabrics of unvarying quality and optimal dimensions.

- Versatility: Equipped to work with synthetic, natural and blended fibers to generate fabrics for specific purpose.

- Innovative Fabrication Techniques: With the special production requirements of multi-axial weaving, non-woven processing technology and warp knitting technology.

- High Output Efficiency: Intended for heavy production with fast sequences to achieve timely and efficient production for the customer.

- Customizability: Machines can also be versatile and manufacturers can change configurations depending on textile type; fire resistant fabrics or fabrics that wick moisture.

- Sustainability Features: Most technical textile technologies involve the re-processing of waste fibers or the use of energy conserving manufacturing processes.

Applications of Technical Textile machine :

- Geotextiles: As construction equipment for road construction, soil reinforcement and agricultural drainage purposes, these machines create robust fabric for long-term environmental use.

- Medical Textiles: Develop exacting materials for plasters, surgical aprons and orthopaedic bandages which should have high standard of cleanness and safety.

- Protective Fabrics: Vital to generate heat-resistant, chemical and bullet-proof fabrics to be used in policing, fire-fighting services, and industries where employees operate in dangerous environments.

- Industrial Composites: Produce fabrics with high strength and light density that can be used for automobile, aircraft parts, and constructions for upgraded demanding reinforcements.

- Sports and Performance Wear: Create sweat-receptive, quick dry, stretchable and springy fabrics primarily intended for sportswear and sports accessories.