Terry Warp Knitting with the Versatile 3-Guide-Bar Tricot Machine

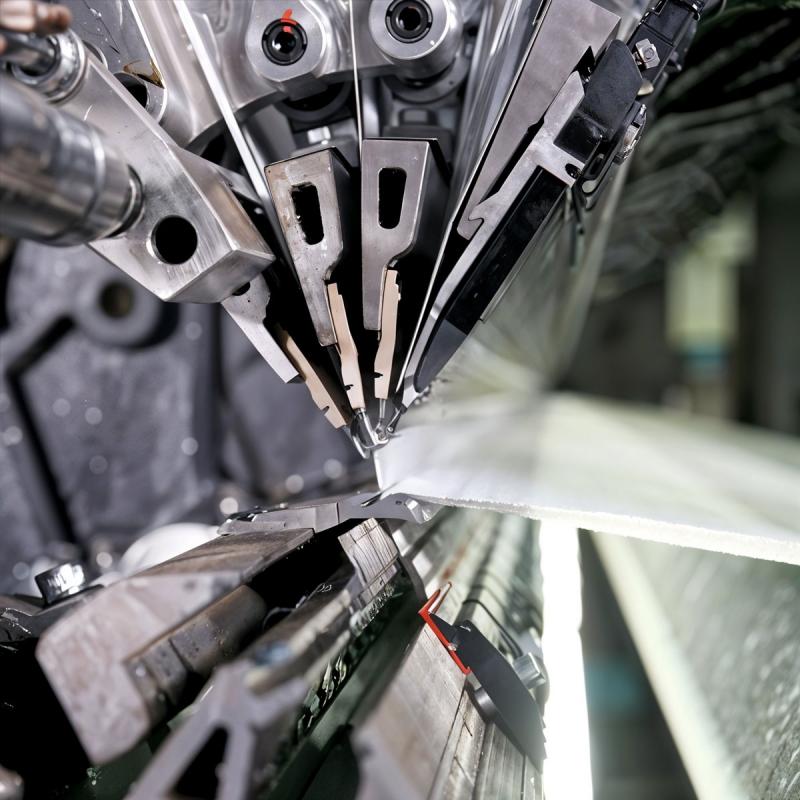

Warp knitting machines have changed a lot in recent years. New designs and better technology have made them more efficient. One example is Grand Star’s Tricot Knitting Machine with 3 guide bars. It has a special needle bar arrangement. It also has compound needles. These features help make fabric formation better. This design gives control over stitches. As a result, different textures can be made.

More and more industries need high-quality terry fabrics. Why is that? Terry fabric is soft and absorbent. It is used in many products, like towels and clothing. This is why there is a growing demand for better knitting machines.

Understanding the 3-Guide-Bar Tricot Knitting Machine

How the 3-Guide-Bar System Enhances Knitting Precision

The 3-guide-bar system makes knitting more precise. But how does it work? The machine has several guide bars that move by themselves. These guide bars control the fabric pattern. They can slide different distances. This movement creates different patterns and textures on the fabric. Isn’t that useful for manufacturers?

The machine also has an advanced take-up and let-off system. This system keeps the fabric tension even. The take-up system is electronic. This means it controls the tension well during the whole process. The let-off system works with each warp beam. This ensures the yarn tension stays correct. If the tension is not right, the fabric may have defects. So, this feature helps produce high-quality fabric every time.

Key Features and Benefits for Textile Manufacturers

This machine offers many benefits. It helps make fabrics with high precision. Manufacturers can create different textures and patterns. It also reduces errors. That means there is less waste. Since the tension control is automatic, the fabric always stays in good shape. Wouldn’t that save time and money? Many textile factories need machines that work fast. This machine is made for speed. It knits fabric quickly without losing quality. It is also reliable. This means manufacturers can produce more fabric in less time.

Why Choose This Machine for Your Business?

Comparison with Traditional Knitting Machines

This machine is different from older knitting machines. It has modern features that improve quality. For example, it has an integrated monitoring system. This system uses lasers and cameras to check fabric quality. If there is a problem, the machine can fix it right away. Because of this, there is less waste. Also, every piece of fabric looks the same. That is important for businesses that sell high-quality products.

The machine also has a special control system. It is called the GrandStar® COMMAND SYSTEM. This system makes it easy to control the machine. The screen is simple to use. Workers can adjust the machine settings quickly. This makes the process smooth. Wouldn’t that make work easier?

Return on Investment and Long-Term Value

This machine is a good investment. It uses energy efficiently. The drive system is designed to save power. This makes it good for the environment. It also lowers electricity costs. Businesses can save money over time.

Since the machine reduces waste and improves fabric quality, it helps businesses make more profit. It is also built to last. Manufacturers can use it for many years without problems. Because of this, businesses can see a high return on investment.

Advantages of Terry Warp Knitting in Wholesale Production

Increased Efficiency and Fabric Consistency

Terry warp knitting machines work fast. They produce fabric at high speed. This helps businesses meet demand. The machines also make fabric with the same quality every time. The stitches stay even. The patterns do not change. This is important for manufacturers. Customers want fabrics that look and feel the same in every batch.

The machine also has automatic tension control. This keeps the fabric structure stable. When tension is not right, defects can happen. But with this machine, the yarn stays tight and smooth. This makes the final product better. It also reduces waste. Less waste means more profit for businesses.

Cost-Effectiveness and Scalability for Large-Scale Manufacturing

This machine saves money. It uses energy well. It does not waste power. This lowers electricity costs. Businesses can produce more fabric without spending too much. That makes it a good investment.

It is also good for large-scale production. Factories need machines that can run for long hours. This machine is strong and reliable. It does not break easily. Fewer breakdowns mean less downtime. When machines keep running, factories can make more products. This helps them grow and take bigger orders.

Applications and Market Potential

Industries Benefiting from Tricot Warp Knitting Technology

Many industries use fabrics made with tricot warp knitting. The fashion industry is one of them. This machine makes lightweight and breathable fabrics. These fabrics are used in clothes. Designers like them because they are soft and smooth.

Technical textiles also use this technology. Some industries need fabrics that perform well under pressure. The automotive, medical, and construction industries use these fabrics. They need strong and durable materials. This machine helps make fabrics that last long and handle tough conditions. Home textiles also benefit. Upholstery fabrics, curtains, and bedding need special patterns. This machine makes large and detailed designs possible. It is useful for making stylish home decor. Sportswear is another big industry. This machine makes fabrics that control moisture. Athletes need clothes that stay dry. This fabric helps keep them comfortable. It is perfect for high-performance sportswear.

Global After-Sales Support and Expansion Plans

Our after-sales service covers many countries. We have teams in Turkey, India, Vietnam, Indonesia, and the USA. We also plan to expand to more places. In areas without local support, we help online first. Our team gives real-time guidance. If needed, we send engineers to fix issues. This ensures that our customers get the best service.

Boost Your Business with the Best Terry Warp Knitting Machine!

This machine makes production faster. It creates high-quality fabric. Stitches stay even, and patterns stay perfect. Automatic tension control prevents defects. This saves time and reduces waste. It is strong and built to last. It runs for long hours without stopping. It uses less power. This helps lower costs. It lets businesses grow and take more orders. Many industries trust this machine. It makes fabric for clothing, home decor, sportswear, and more. It is perfect for large-scale production.

Upgrade your factory today. Increase efficiency. Contact us now!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.