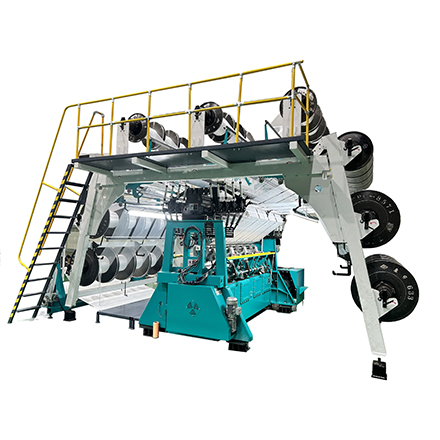

Triple Jacquard Double Raschel 7/3

| Triple Jacquard Double Needle Bar Raschel Machine – Warp Knitting Machine | |

| Model No. | GS-RDPJ 7/3 (EL) |

| Ground Bars | 4 Bars |

| Jacquard Bars | 6 Bars (3 Group) |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- TECHNICAL DATA

- TECHNICAL DRAWINGS

-

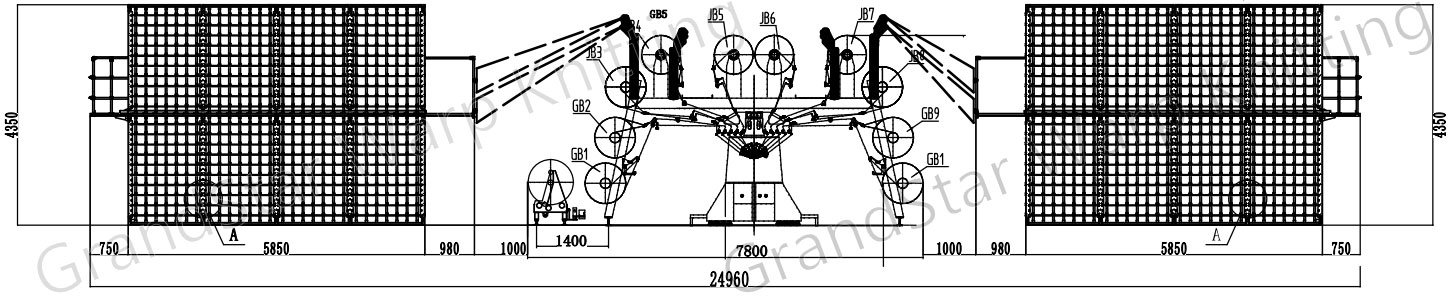

Working width / Gauge:

3454 mm = 136″

E18, E22, E24, E28

-

Knock-over comb bar distance:

2–12 mm, continuously adjust able. Central trick plate distance readjustment

-

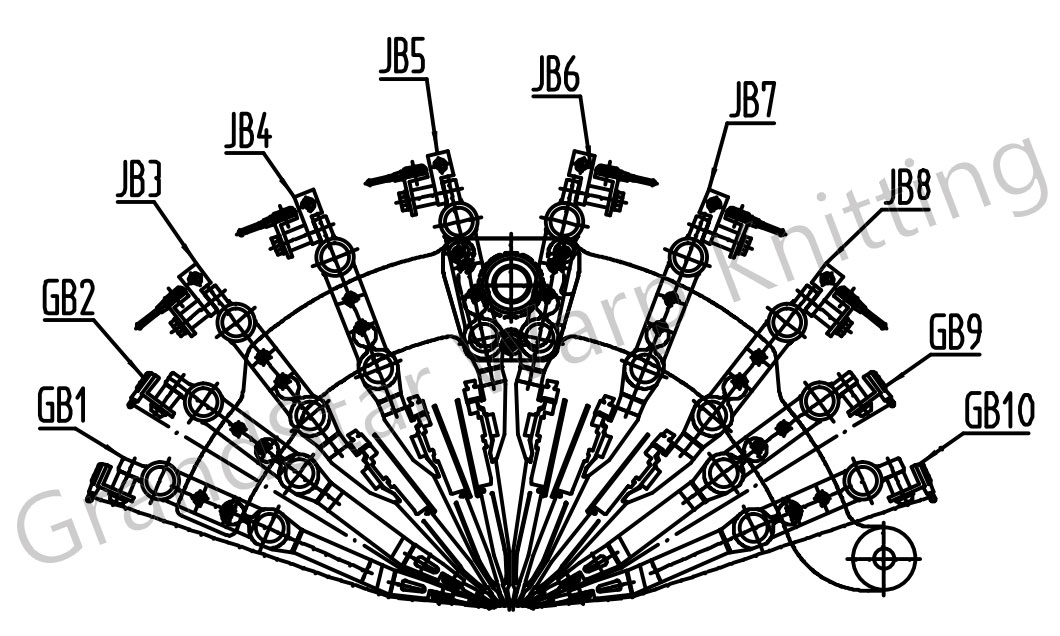

Bars / knitting elements:

Four ground guide bars, Three Group Piezo Jacquard guide bar (split execution);

GB3, GB4, JB5 and JB6 stitch forming on both needle bars.

Two individual latch needle bars, two knock-over comb bars, two stitch comb bars

-

Warp beam support:

10 × 812 mm = 32″ (free-standing)

-

GrandStar®(GrandStar COMMAND SYSTEM)

Operator interface to configure, control and adjust the electronic functionality of the machine

-

Yarn Iet-off device

For each completely mounted warp beam position: one electronically controlled yarn Iet-off drive

-

Fabric take-up

Electronically regulated fabric take-up, driven by geared motor, consisting of four rollers.

-

Batching device

Separate rolling device

-

Pattern drive

Electronic guide bar drive EL, all guide bars shog up to 150 mm

-

Electrical equipment

Speed-regulated drive, total connected load of the machine: 7.5 KW

Voltage: 380V±10% three-phase power supply, main power cord requirements: not less than 4m㎡ three-phase four-core power cord, ground wire not less than 6m㎡

-

Oil supply

Heating and cooling by means of circulating air heat exchanger, filter with dirt-monitoring system

-

Equipment working conditions

Temperature 25℃±3℃, humidity 65%±10%

Floor pressure: 2000-4000KG/㎡

Training & Service

Installation & Training

Local Service

Application

- Fashion & Apparel: Used in high-end garments, activewear, and accessories like scarves and bags for intricate patterns and durability.

- Home Textiles: Ideal for upholstery, curtains, drapes, and bedding due to its decorative design and strength.

- Technical Textiles: Suitable for automotive interiors, industrial fabrics, and protective clothing due to its robustness.

- Textile Arts & Crafts: Perfect for tapestries, wall hangings, and embroidery projects with detailed patterns.

- Luxury Fabrics: Common in couture, bridal, and special event wear, offering unique, luxurious designs.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |