Warp And Weft Direction for elastic yarn

| Direct Warper for elastic yarn – Warping Machine / Warp Preparation | |

| Model No. | GS-DSE 21/21 EC |

| Application | Elastic Yarn |

| Beam Size | 21*21 |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

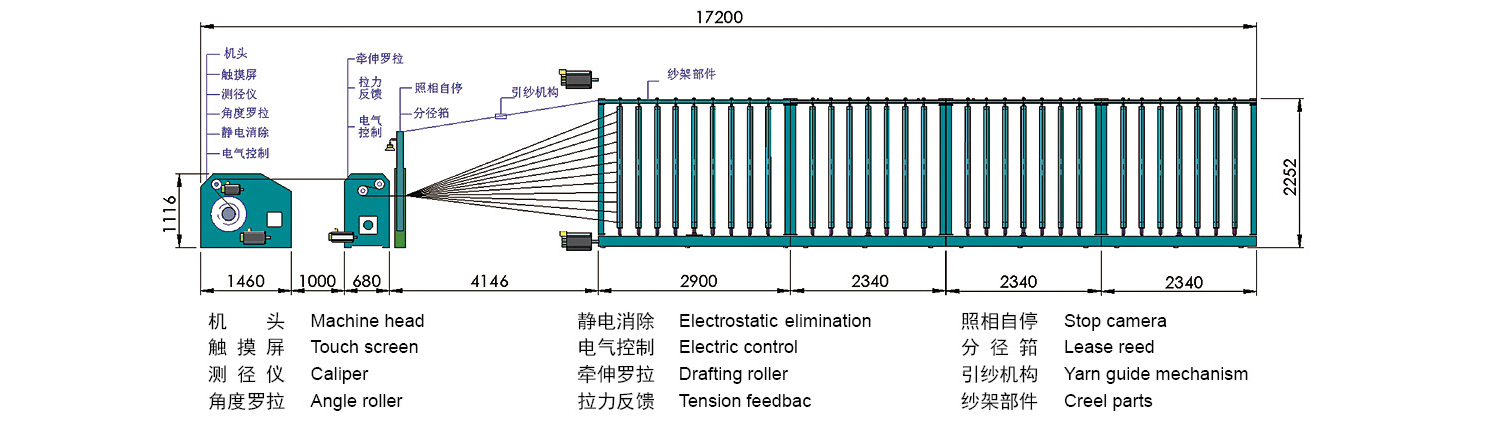

| GS-DSE HH 21-21 EC | |

| Technical facts | |

| GS-DSE HH 21-21 EC | |

| Max. creel speed | up to 300 m/min |

| Sectional beam size | 21 inches + 21 inches |

| Max. yarn tension | 150 N |

| Laser measure range | 250 mm |

| Highest beam circumference control | By automatic layer thickness control |

| Three stretching zones | Final stretching up to 100% |

- High-Precision Alignment: The machine employs cutting-edge technology to accurately detect and adjust the alignment of warp and weft threads for flawless fabric weaving.

- User-Friendly Interface: With an intuitive control panel, operators can quickly calibrate the machine, saving valuable time in setup and operation.

- Robust Construction: Built with high-quality materials, the machine is durable and designed to withstand continuous industrial use.

- Versatile Compatibility: Suitable for a wide range of fabrics, including cotton, silk, polyester, and blends, ensuring adaptability to various production needs.

- Real-Time Monitoring: Equipped with advanced sensors and a display system, it offers real-time feedback to ensure alignment accuracy.

- Energy Efficient: Designed to consume minimal power, it reduces operational costs while maintaining high performance.

Training & Service

Installation & Training

Technical support is a cornerstone of our warp knitting machine services. To ensure our customers maximize the performance of their machines, we provide comprehensive training programs in multiple formats.

Local Service

Our commitment to exceptional after-sales service extends to Turkey, India, Vietnam, Indonesia, and the USA, with plans to expand our local service teams to additional countries in the near future.

Application

- Textile Mills: Streamlines the weaving process, ensuring uniformity in fabric production.

- Garment Manufacturing: Reduces defects caused by misalignment, ensuring high-quality outputs.

- Quality Control: Enables precise inspections in textile labs for research and development purposes.

- Custom Fabric Production: Ensures exact alignment for intricate designs and patterns in custom weaving projects.

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |