What Are the Types of Warp Knitting Machines

Warp knitting is a fast knitting method. It makes strong and stretchy fabrics. There are many kinds of warp knitting machines. But they all have a similar basic structure. Each type has different parts because they do different jobs. They also have extra tools for special needs.

Warp knitting is not like weft knitting. In warp knitting, the yarns move in parallel lines. They go straight into the machine. This method helps make fabric quickly and evenly. Warp knitting is used in many areas. It is popular in fashion and sportswear. It is also used in car seats and industrial fabrics. Do you want to know more about the types of warp knitting machines? Let’s dive in!

Meet Grand Star Technology

Your Partner in Warp Knitting Machines

Grand Star makes warp knitting machines. The company follows three main ideas: new thinking, trust, and customer care. These ideas help them do better work for every customer. Grand Star is more than just a machine maker. The company works to improve textile making for the future.

It offers many types of machines. These include Raschel, Tricot, Double-Raschel, Lace, Stitch-Bonding, and Warping machines. The team can adjust both the machine parts and the control systems. This helps customers make new fabric designs. The machines mix smart control tools with exact mechanical parts. This makes them work well with the changing textile world.

A Global Leader in Warp Knitting

Grand Star has led warp knitting since 2012. From the start, the company wanted to change how textiles are made. It brings in new ideas to help work faster, better, and cleaner. This focus helps customers get strong and smart machines. The company is known for top-quality tools and clear thinking. Its goal is to push the textile field forward step by step.

Experts in Machine Design

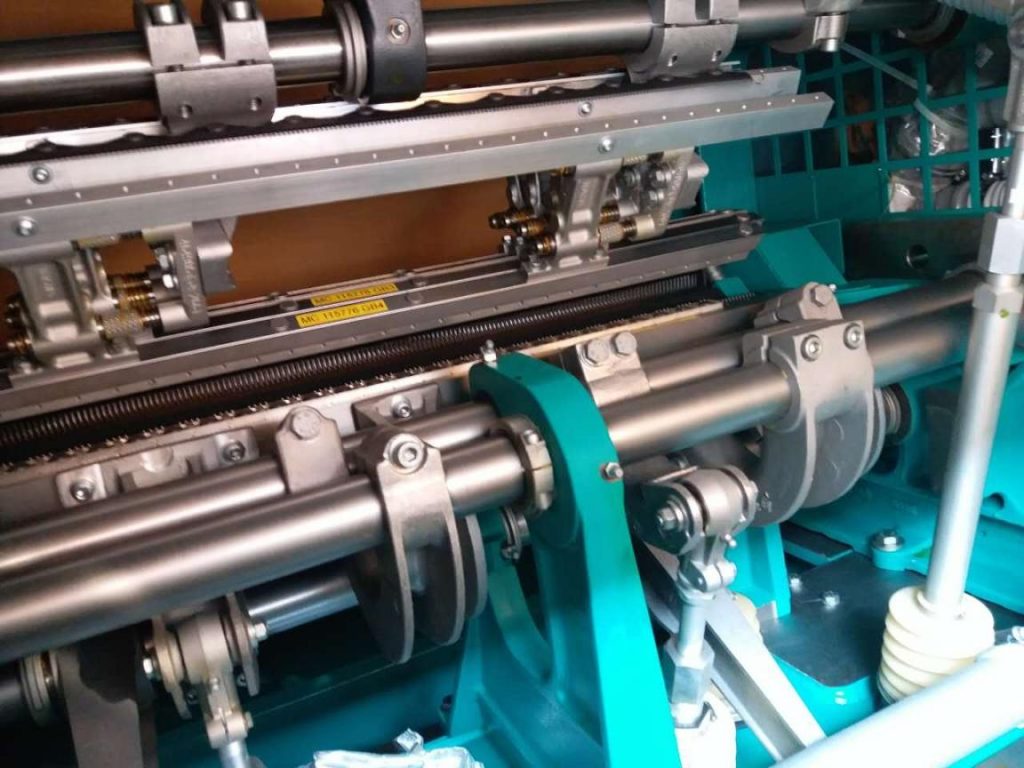

Grand Star makes high-level warp knitting machines. It builds each machine with care and skill. The team focuses on how machines work and how long they last. They also support each customer before and after buying the machines. The team listens and helps with every need.

Trusted Around the World

The main office is in Fujian, China. But the company works with many countries. These include the United States, Japan, Turkey, Vietnam, Indonesia, India, Colombia, and Mexico. Grand Star has become a top name in many places. Many fabric makers trust the company for strong machines and good help.

Number of Warp Knitting Machine‘s Needle Beds

Single-Needle Bed Machines

Warp knitting machines can have different numbers of needle beds. Some machines have only one needle bed. These are called single-needle bed machines. They are simple in structure. They are often used for making basic fabrics. These machines work well for light and soft materials. They are easy to run and fix. Many factories choose them for fast and steady work. Single-needle machines are a good choice when the fabric design is not too complex.

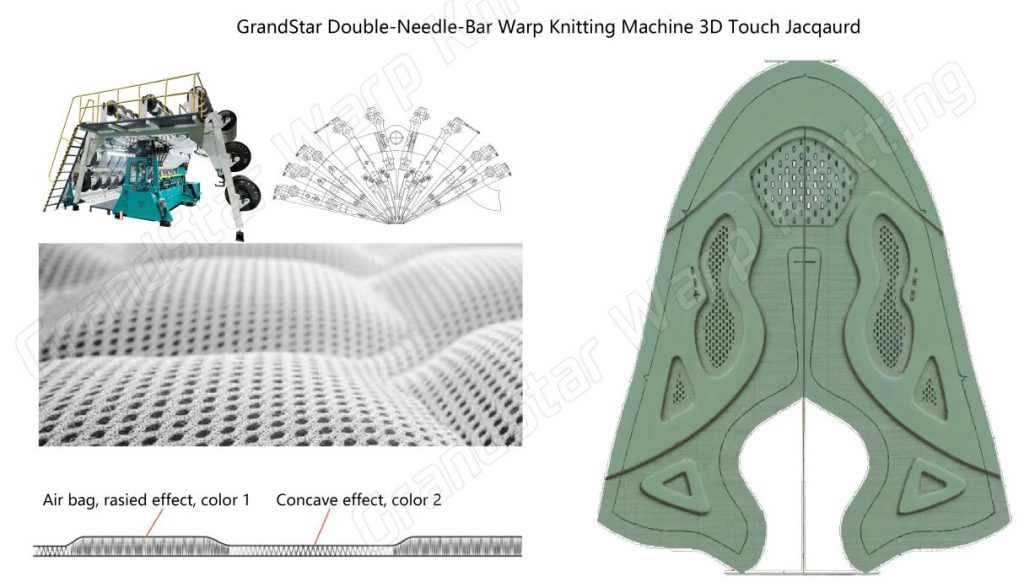

Double-Needle Bed Machines

Other machines have two needle beds. These are called double-needle bed machines. They can make more complex fabric patterns. The fabrics are often thicker and stronger. These machines are used when the product needs more shape or structure. They are often used for 3D fabrics or technical textiles. These machines can also help make spacer fabrics. They offer more design options for advanced textile needs.

Types of Warp Knitting Machine‘s Knitting Needles

Crochet Needle Machines

Warp knitting machines use different kinds of needles. One type is the crochet needle. This kind is simple and strong. It works well for making nets, lace, and mesh fabrics. Many factories use it for low-stretch fabrics. The crochet needle has a hook. This hook pulls the yarn through loops. The machine is easy to use and needs little maintenance. It is good for basic designs and open fabric structures.

Tongue Needle Machines

Another type is the tongue needle machine. This machine is used for many fabric types. It can make both light and heavy fabrics. The needle has a small latch. The latch opens and closes to move the yarn. This needle type is flexible. It can help make detailed and tight fabric designs. Many factories like it because it offers more design options.

Compound Needle Machines

The last type is the compound needle machine. It has two needle types: grooved needle and tubular needle. These needles work together to hold and move the yarn. Compound machines are used for fine and smooth fabrics. They give high speed and clean results. These machines are common in modern textile factories.

Direction of Warp Knitting Machine‘s Fabric Drawing-Out

Tricot Warp Knitting Machines

Warp knitting machines can be grouped by the way the fabric comes out. One kind is the Tricot warp knitting machine. In this machine, the fabric moves down while it is being made. This type is often used for smooth and light fabrics. It is good for underwear, linings, and other soft items. Tricot machines do not have a grid-shaped shedding plate. Instead, the big sinker takes on this job. It holds the loops and moves the fabric. The machine works at an angle of about 110 degrees between the fabric and the needle bed.

This angle causes a strong pulling force on the needles. When the tension gets too high, the needles can bend. This is common when using fine crochet needles. These thin needles do not have strong stiffness. Composite needles are stronger. They can handle more tension. But if the yarn is pulled too hard, the loop can slip back, and the machine may stop working well.

Raschel Warp Knitting Machines

Another type is the Raschel warp knitting machine. This machine pulls the fabric backward during knitting. It has a comb-shaped shedding plate that holds the fabric. The angle between the fabric and the needle bed is about 160 degrees. This setup keeps the fabric nearly flat with the needles. The pulling force on the needles is low. This reduces bending of the needle, even with more tension. Raschel machines are better for thicker fabrics and complex patterns. They can run smoother under heavy loads. They are often used for technical fabrics, nets, or lace that need strong support.

Innovations in Control and Automation

Smart Control Panels with Real-Time Monitoring

Grand Star uses smart control panels in its machines. These panels are easy to use. They help users check machine status at any time. The system shows clear updates on speed, yarn use, and fabric output. Real-time data helps workers catch problems early. It also helps them fix issues fast. This lowers errors during production. Each machine works better when problems are found and solved quickly. These control panels help save time. They also help improve the quality of the fabric.

Digital Interface for Custom Patterns

Grand Star machines have digital screens for setting patterns. Users can create and change fabric styles with just a few clicks. The system allows for fast updates. There is no need to stop the machine. The operator can make changes while the machine runs. This makes the whole process smooth and quick. Each design can be saved and reused. This helps with large orders or repeat patterns.

AI for Maintenance and Performance

Grand Star uses AI to help with machine care. The system gives alerts when parts need checking. This helps reduce sudden stops. The machine runs longer without breaks. This saves time and costs. AI also tracks how each part is working. It tells the team what needs repair. This means fewer breakdowns and better fabric output.

Sustainability and the Future

Energy-Saving Designs

Grand Star builds machines that use less power. Each design is made to run smoothly with low energy. Less power use means lower factory costs. It also helps protect the environment. This is important for today’s textile industry. Using less energy does not mean lower performance. The machines still work fast and strong.

Recyclable Yarn and Less Waste

Grand Star machines work well with recyclable yarns. They help turn waste into useful products. This supports eco-friendly fabric making. Each step in the process uses just enough yarn. The system avoids extra waste. This helps reduce cost and saves materials. The machines are made to work clean and smart.

A Greener, Smarter Future

Grand Star wants to lead the way in green warp knitting. The team works on better, cleaner machines. They also test new ideas often. The goal is to make warp knitting smarter and more earth-friendly. Every new model brings better tech and lower waste.

Explore Warp Knitting Machine Types with Grand Star

There are many kinds of warp knitting machines. Each one works in a different way. Some use one needle bed. Others use two. Some pull fabric downward. Others pull it backward. Some use crochet needles. Others use compound or tongue needles. Each type makes a special kind of fabric.

Grand Star builds all these machines. They are strong, fast, and easy to run. You can choose the one that fits your fabric needs. Try Grand Star‘s warp knitting machines. Find the best type for your factory today!

Hey, I’m Vincent!

Solving complex challenges with precision and creativity in the warp knitting industry. Passionate about advancing textile engineering and turning innovative ideas into reality. Shaping the future of warp knitting.