Warping Creel

| Warping Creel (Swivel-frame) For Warping Machine | |

| Model No. | Swivel-frame |

| Application | For Warping Yarn |

| Certification | CE |

| Quality | One Year Guaranteed |

| Incoterms | FOB,CFR,CIF,EXW |

| Payment Terms | L/C,D/A,D/P,T/T or To be negotiated |

- PRODUCT DETAILS

- TECHNICAL DATA

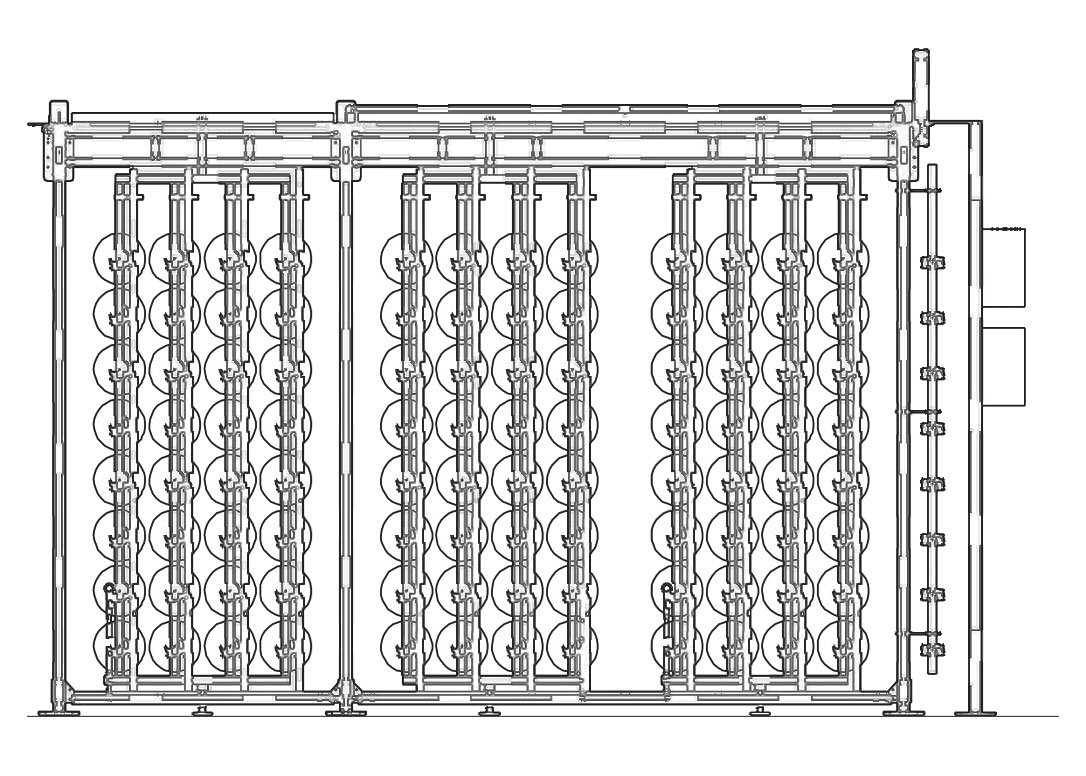

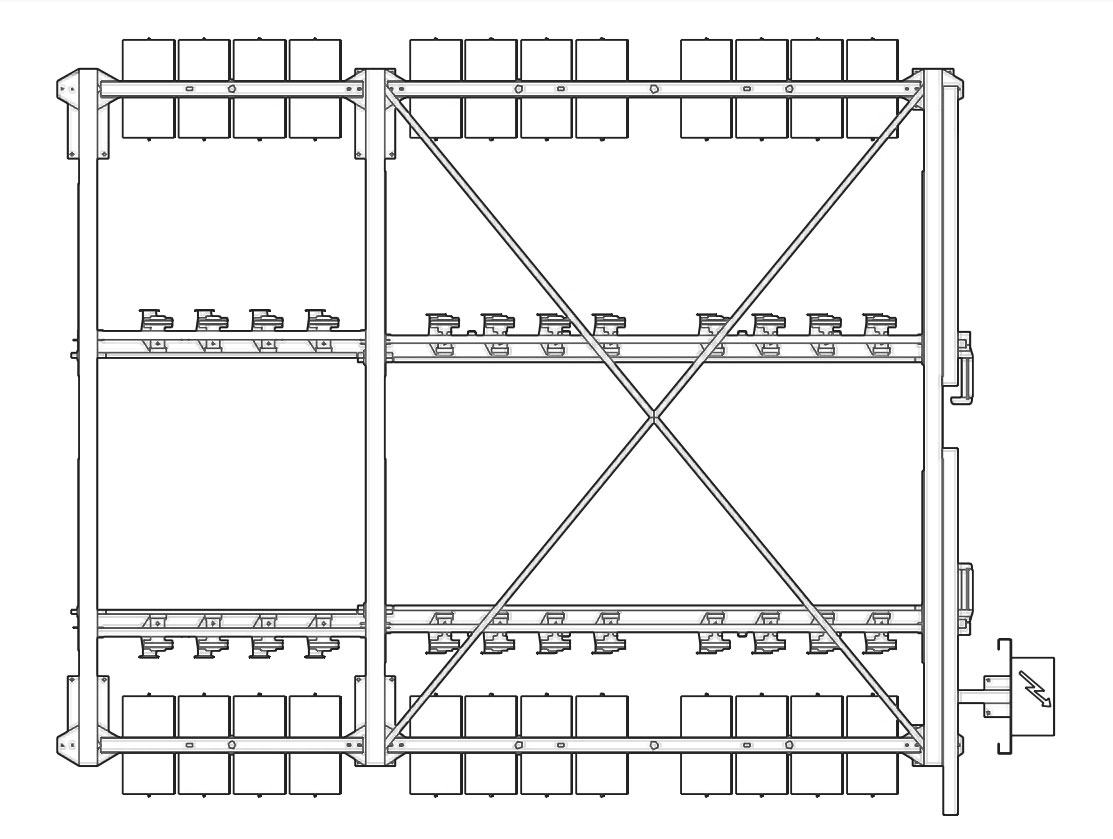

Warping Creel / Swivel-Frame Creel: Efficiency, Precision, and Flexibility

For modern textile production, efficiency and precision in warping are critical. Our Warping Creel and Swivel-Frame Creel set the industry benchmark with innovative technology designed to enhance yarn handling, reduce downtime, and optimize production speed. Unlike conventional creels, our advanced system is engineered for versatility, ensuring superior performance across a wide range of yarn types and applications.

Advanced Technical Capabilities

- Raw Material Compatibility: Supports cotton, regenerated fibers, synthetics, wool, and blended yarns, making it suitable for diverse textile applications.

- Swivel-Frame Creel: Designed for spun, filament, and technical yarns, providing unmatched adaptability in modern textile operations.

- V-Creel for Direct Warping: Ideal for fine and coarse spun yarns, reducing yarn stress and enhancing warping efficiency.

Key Advantages Over Competitors

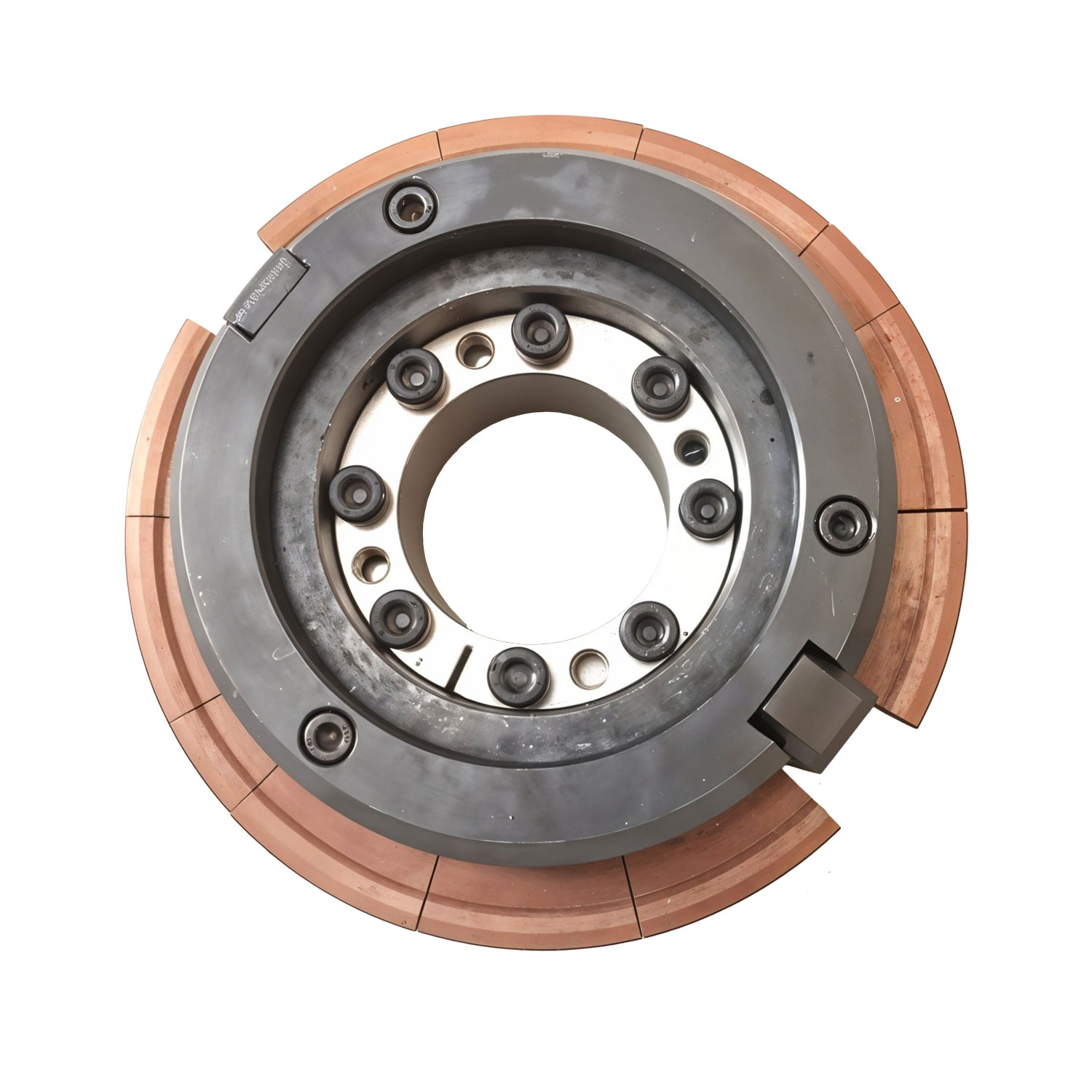

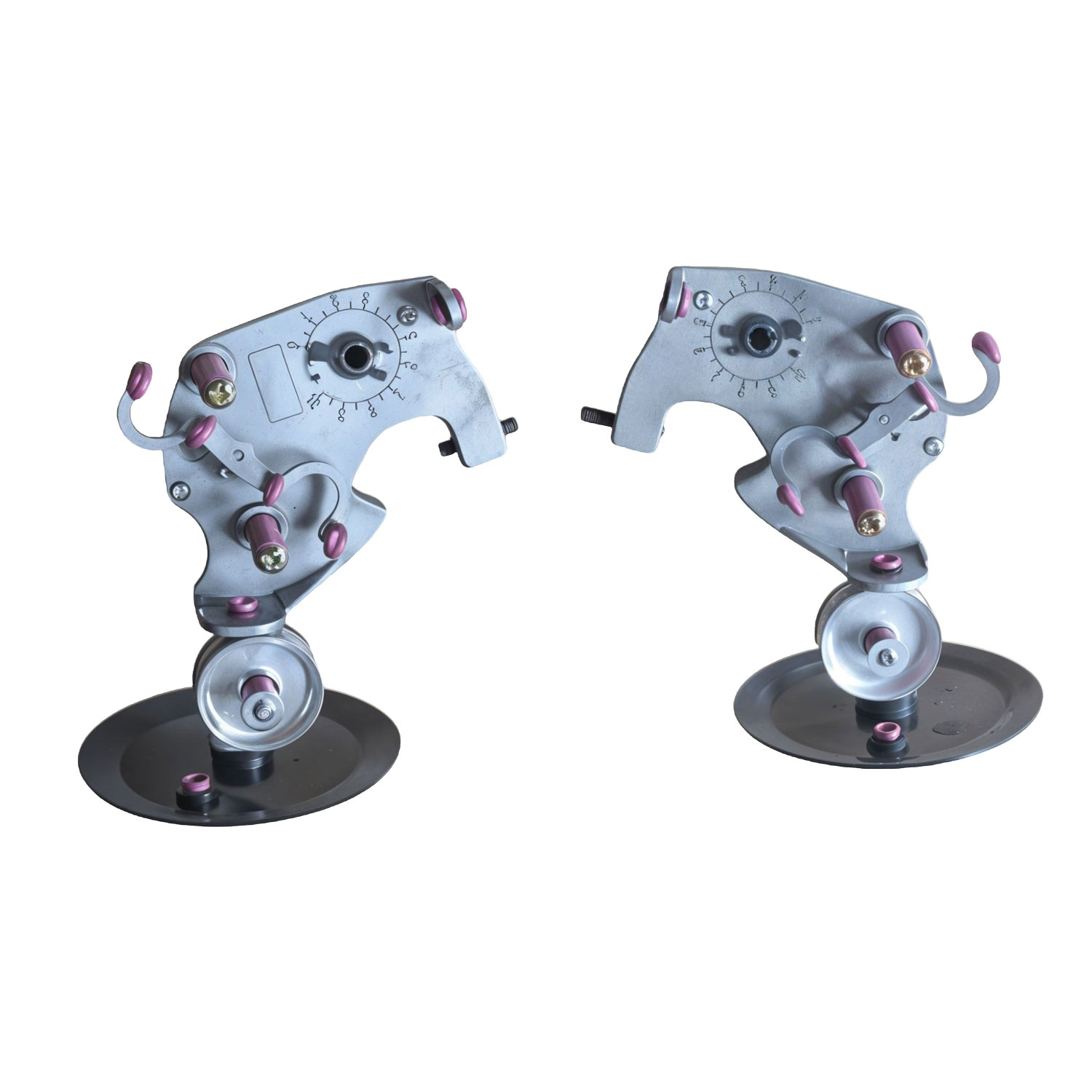

1. Precision-Controlled Yarn Tension

Our automatic pre-tensioner ensures controlled warp tension, preventing snarling and inconsistencies at machine start-up. This feature provides higher yarn quality and eliminates common issues found in conventional creels.

2. Higher Speeds with Reduced Downtime

- V-creels minimize friction points during unwinding, allowing the machine to operate smoothly at speeds of up to 1200 m/min without compromising yarn integrity.

- Easy threading system significantly reduces setup time, minimizing machine downtime and boosting overall efficiency.

3. Uninterrupted Production with Reserve Loading

Our swivel-frame creel includes reserve loading, allowing for continuous operation by enabling creel loading even during production. This innovation enhances workflow efficiency and minimizes stoppages.

4. Customizable Yarn Handling Solutions

- Parallel creel options available with a choice of yarn tensioners, ensuring adaptability to different yarn requirements.

- Balloon limiters optimize yarn flow and minimize stress on the fibers, reducing wear and improving consistency.

- Touch-free end monitoring ensures real-time supervision and enhances operational accuracy.

The Ideal Solution for High-Performance Warping

By integrating state-of-the-art features, our Warping Creel and Swivel-Frame Creel outshine traditional creeling systems. Whether working with spun, filament, or technical yarns, our solution provides the precision, flexibility, and high-speed performance demanded by today’s textile manufacturers.

Experience the difference with our cutting-edge creeling solutions and elevate your warping process to the next level.

Application

- Knitting Machines: To feed yarn during knitting processes in order to minimize cases of yarn breaks and maintain fabric uniformity.

- Weaving Machines: Imperatively favorable for controlling yarn flow during fabric formation, making it possible to produce even fabric without frequent halts.

- Embroidery Machines: Avoids interconnection of the threads, which is vital for the smooth flow of threads when producing embroidered material.

- Textile Manufacturing: Versatile it can be applied to different types of fabric production, enhancing the productivity of mechanical systems that need constant yarn supply.

| Model | Tiers | Spacing | Draw-off from Outside | Draw-off from Inside |

|---|---|---|---|---|

| GS-SP | 6 | 320–320 | ✔ | ✔ |

| 6 | 360–360 | ✔ | ✔ | |

| 8 | 240–240 | ✔ | ✔ | |

| 8 | 270–270 | ✔ | ✔ | |

| 10 | 220–220 | ✔ | ✔ | |

| GS-SP-ISOTENS | 7 | 300–300 | ✔ | ✔ |

| 8 | 240–240 | ✔ | ✔ | |

| 8 | 270–270 | ✔ | ✔ | |

| GS-F | 5 | 460–460 | ✔ | ✔ |

| 6 | 320–320 | ✔ | ✔ | |

| 6 | 380–380 | ✔ | ✔ | |

| 8 | 240–240 | ✔ | ✔ | |

| 8 | 270–270 | ✔ | ✔ | |

| 10 | 220–220 | ✔ | ✔ | |

| GS-T | 5 | 360–360 | ✔ | ✔ |

| 6 | 360–360 | ✔ | ✔ |

Package and Shipment

|

|

|

Waterproof PackagingAll products are securely sealed using sea-safe packaging to ensure comprehensive protection against water damage during transit. |

Export-Grade Wooden CasesOur compound wooden cases meet international export packaging standards, guaranteeing the safety and integrity of the machinery throughout its journey. |

Reliable Shipping ArrangementsProducts are carefully transported to the designated seaport and expertly loaded into containers for secure and efficient shipping. |